caught between the V-belt and the clutch.Always use

safety gloves.

● Checking and Replacing the V-belt and Clutch

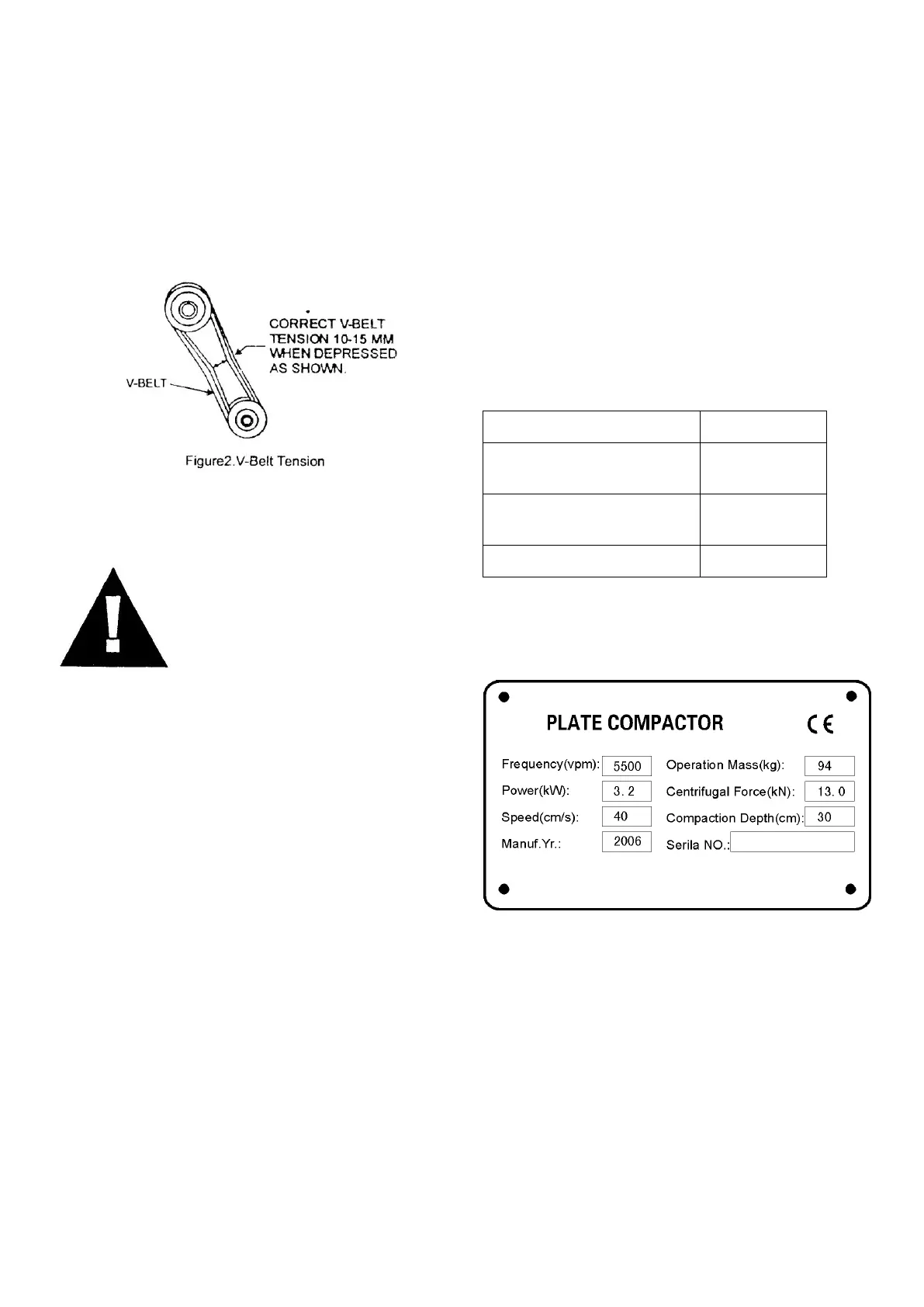

After 200 hours of operation, remove the upper belt

cover to check the V-belt tension(Figure 2).Tension is

proper if the belt bends about 10mm when depressed

strongly with finger between shafts.Loose or worn

V-belts reduces power transmission efficiency,

causing weak compaction and reduces the life of the

belt itself.

Figure2.V-Belt Tension

CAUTION:

whenever the compactor's vibration,

becomes weak or lost during

normal operation regardless of

operation hours,check the V-belt

and clutch immediately.

● Replacing the V-belt

Remove the upper and lower belt covers.Engage an

offsel wrench(13mm) or the like to vibrator pulley

(lower)fastening bolt.Engage waste cloth or the like at

midway of V-belt on the left side and while pulling it

back strongly,rotate the offset wrench clockwise so

that the V-belt will come off.

● Re-installing the V-belt

Engage V-belt to lower vibrator pulley and push the

V-belt to left side of upper clutch and,in the same

manner as in removal, rotate offset wrench clockwise

so that the V-belt goes back on.

● Checking Clutch

Check the clutch simultaneously with V-belt

checking. With belt removed.check outer drum of

the clutch for seizure and "V" groove for wear or

damage with your eyes.Clean the "V" groove as

necessary.Wear Of lining or shoe should be checked

with running check. If the shoe is worn, power

transmission becomes deficient and slipring will

result.

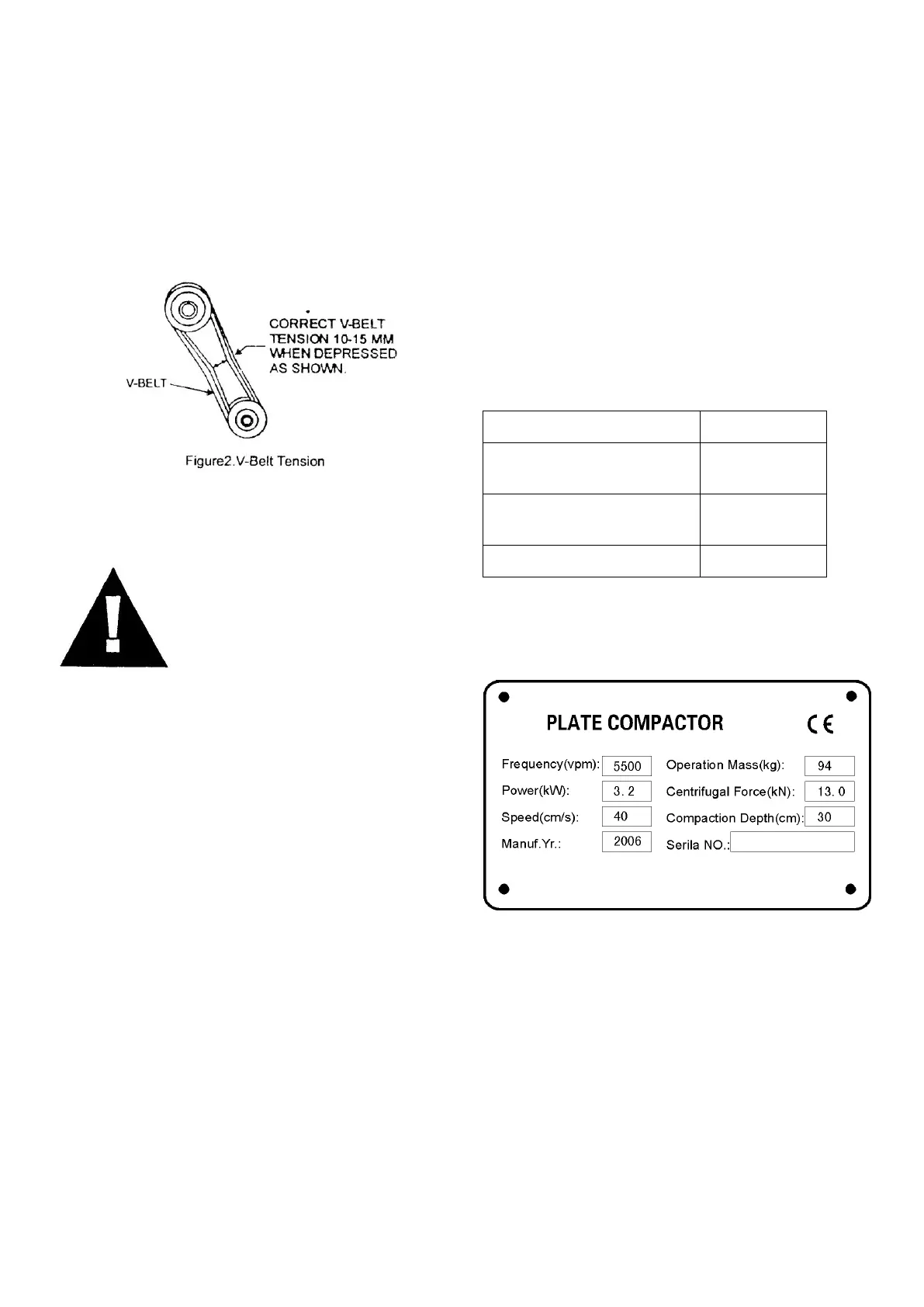

SPECIFICATIONS

motor

61006 Chinese Petrol Engine 4.8 kW output

61007 Petrol, Honda GXl60 4.0 kW output

Governed speed 3.500r/min

Drive Belt

1 x'A',section v belt

Vibrator

Frequency----- 5,500 vibration/min

Centrifugal force----- 13.0 kN

Operation Mass:

61006/61007 84kgs

Acoustic Noise(According to 2000/14/EC)

Loading...

Loading...