General Maintenance

To

increase the service life of the tool and to assure trouble-

free operation few maintenance

in

regular intervals

is

necessary:

At

the end of each working dayclean the machine from saw

dust and dirt. Also clean guide bar, saw chain and air filter.

Make sure that the cutting tool

is

in

proper operation

condition.

Refill the fuel tank and store the tool

in

a dry place.

If you let your chain saw sit idle for a longer period you

should additionally protect the engine against corrosion.

While stopping the engine inject preservative oil through

the carburetor.

You

need not rinse the engine before starting again; just

shake the fuel in the tank thorougly. If engine does not

start immediately spray some gasoline over the air filter.

After the break-in period of about

20-30

operating hours

all screws and nuts of the tool except for the carburetor

screws must be checked for tight seat and must be re-

tightened.

The electrode gap of the spark plug is

0.5 mm (0.02 in) and

should be checked with a feeler gauge from time to time

and adjusted if necessary.

If electrodes of the spark plugs

are badly burned replace spark plugs.

Rinse fuel tank with clean gasoline every 50 operating

hours.

If

necessary also clean strainer of the pick-up body.

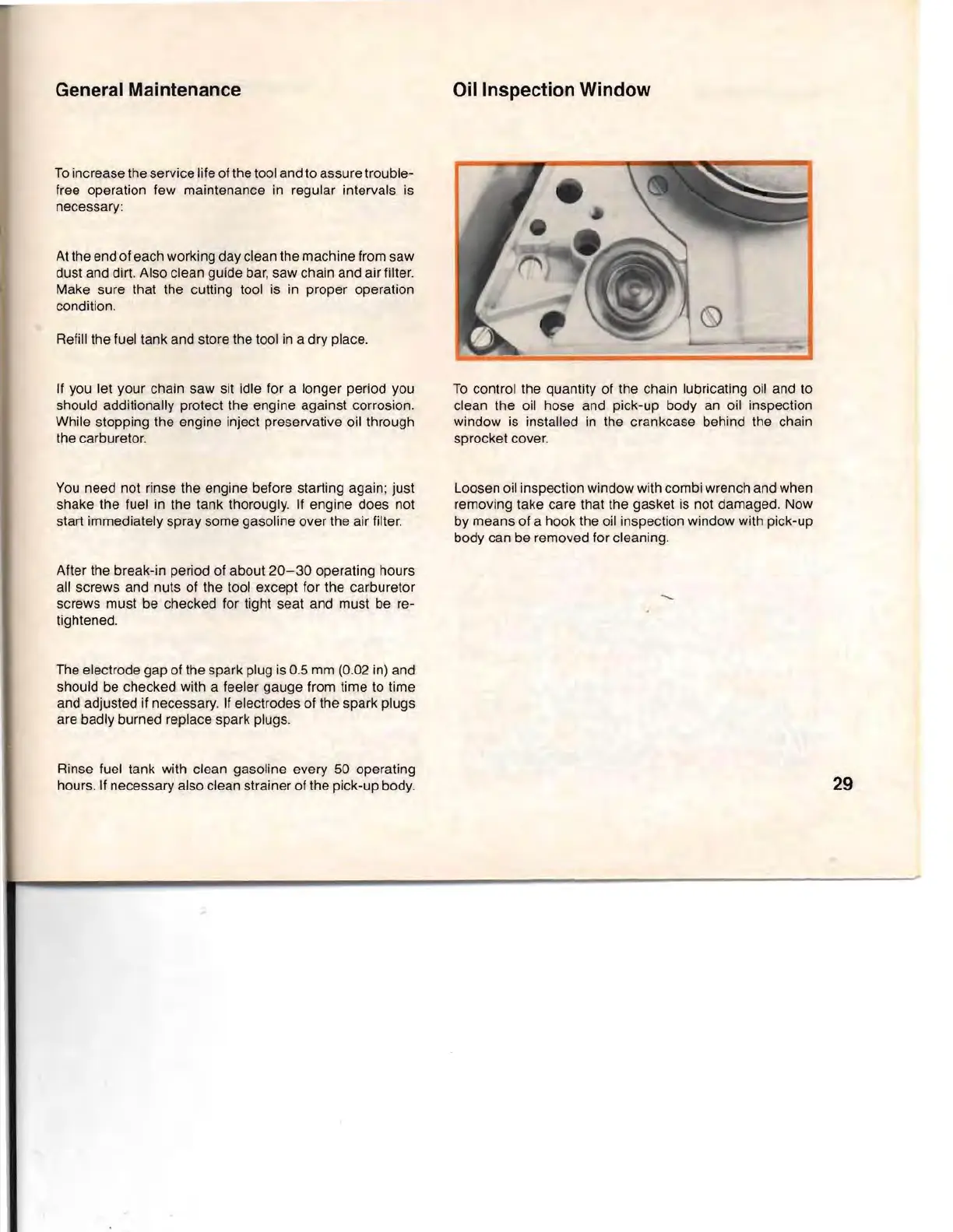

Oil Inspection Window

To

control the quantity of the chain lUbricating oil and to

clean the oil hose and pick-up body

an

oil inspection

window is installed

in

the crankcase behind the chain

sprocket cover.

Loosen oil inspection window with combi wrench and when

removing take care that the gasket is not damaged. Now

by means of a hook the oil inspection window with pick-up

body can be removed for cleaning.

29

Loading...

Loading...