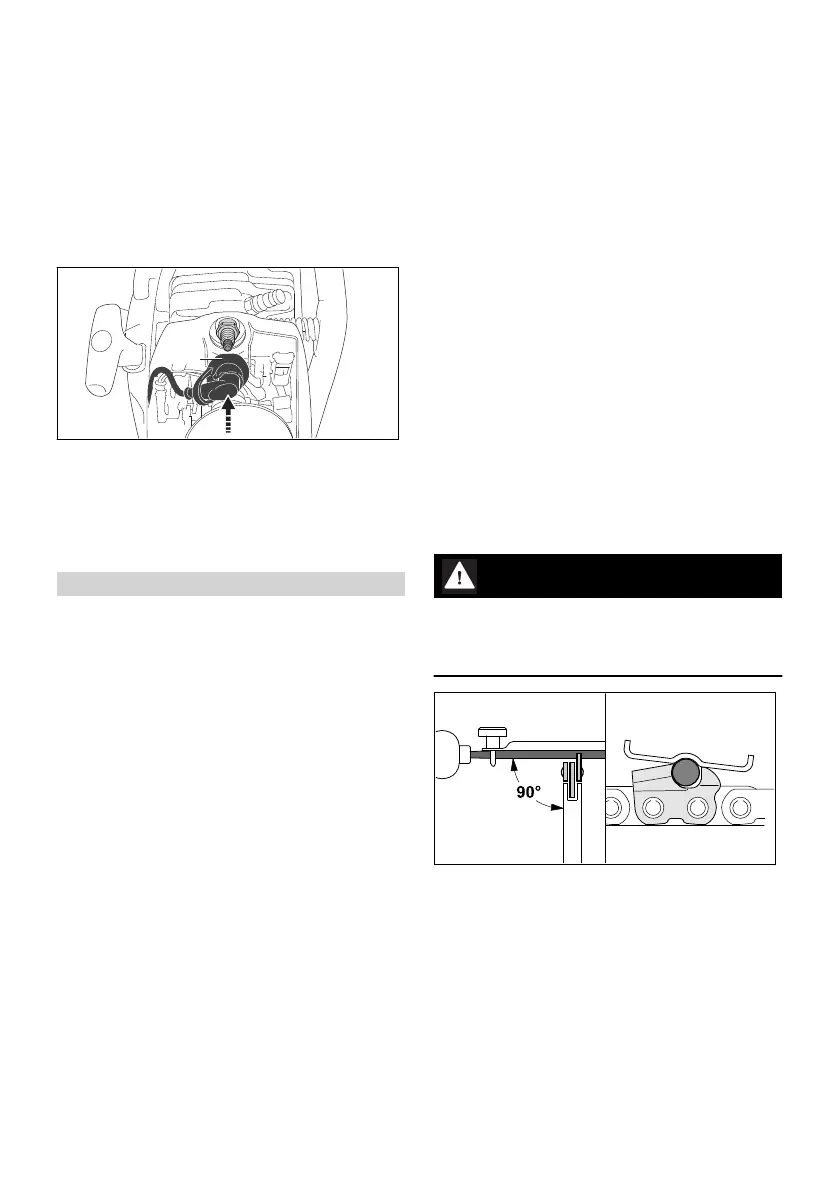

► Rotate the shroud fasteners (1) a quarter turn

counterclockwise.

► Remove the shroud (2).

► Pull off the spark plug boot (3).

► If area around the spark plug is dirty: Clean it

with a damp cloth.

► Unscrew the spark plug.

► Clean the spark plug with a damp cloth.

► If the spark plug is corroded: Install a new

spark plug.

► Insert and tighten down the spark plug.

► Press the spark plug boot (3) firmly home.

► Place the shroud (2) in position.

► Rotate the shroud fasteners (1) a quarter turn

clockwise.

The shroud fasteners are locked.

16 Maintenance

16.1 Maintenance Intervals

The maintenance intervals are dependent on the

environmental and operating conditions. STIHL

recommends the following maintenance inter‐

vals:

Chain brake

► Have the chain brake serviced by a STIHL

servicing dealer at the following intervals:

–

Full-time usage: every 3 months

–

Part-time usage: every 6 months

–

Occasional usage: every 12 months

After every 100 hours of operation

► Install a new spark plug.

Weekly

► Check the chain sprocket.

► Check and deburr the guide bar.

► Check and sharpen the saw chain.

Monthly

► Clean the air filter.

► Have oil tank cleaned by a STIHL servicing

dealer.

► Have fuel tank cleaned by a STIHL servicing

dealer.

► Have pickup body (filter) in fuel tank cleaned

by a STIHL servicing dealer.

Every 12 months

► Have pickup body (filter) in fuel tank replaced

by a STIHL servicing dealer.

16.2 Deburring the Guide Bar

A burr can build up on the outer edge of the

guide bar.

► Remove burr with a flat file or a STIHL guide

bar dressing tool.

► If you have any queries: Contact your STIHL

servicing dealer.

16.3 Sharpening the Saw Chain

Correctly sharpening saw chains requires a lot of

practice.

STIHL files, STIHL filing aids, STIHL sharpeners

and the brochure “Sharpening STIHL Saw

Chains” help you achieve the right results. To

obtain the brochure visit http://www.stihl.com/

sharpening-brochure.

STIHL recommends you have saw chains

resharpened by a STIHL servicing dealer.

WARNING

■ The chain's cutters are very sharp. There is a

risk of cut injuries.

► Wear work gloves made of durable mate‐

rial.

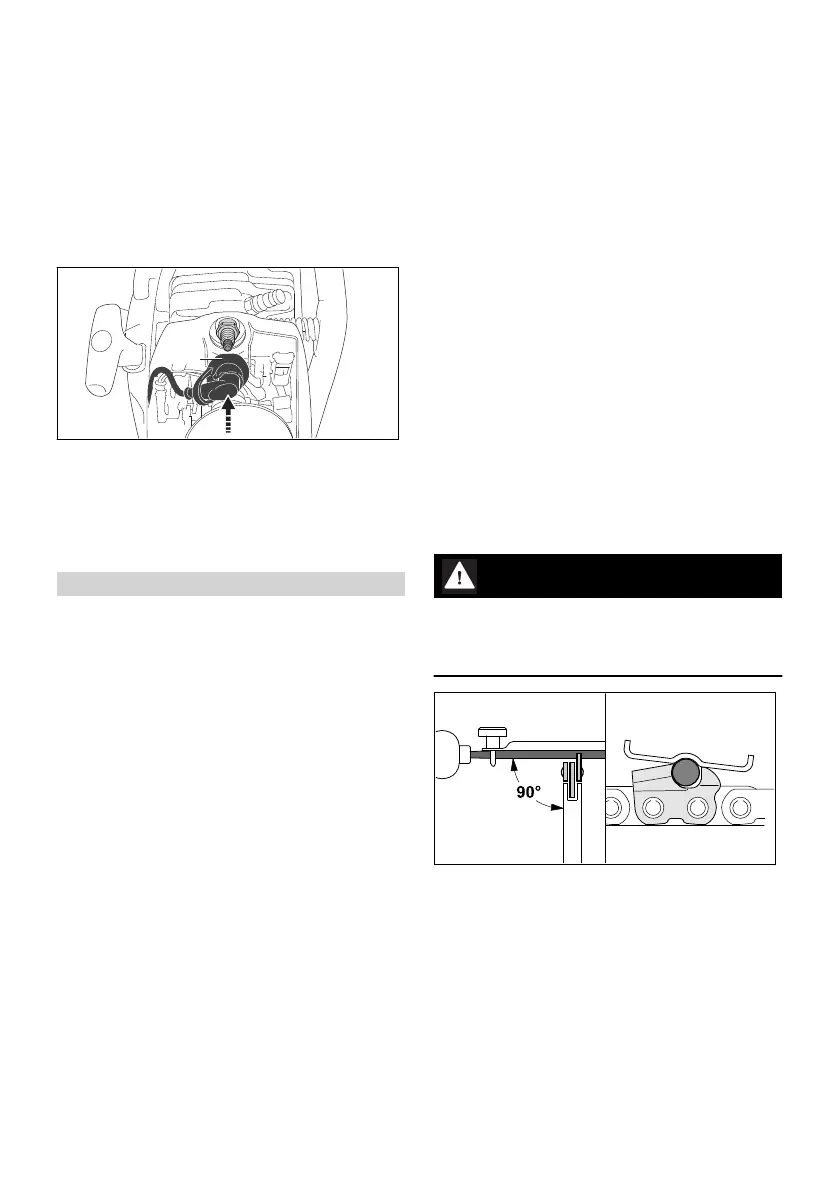

► File each cutter with a round file so that the

following points are observed:

–

Round file matches the chain pitch.

–

File from the inside to the outside of the cut‐

ter.

–

Hold the file at right angle to the guide bar.

–

Maintain a filing angle of 30°.

16 Maintenance English

0458-788-0121-B 25

Loading...

Loading...