-

5

-

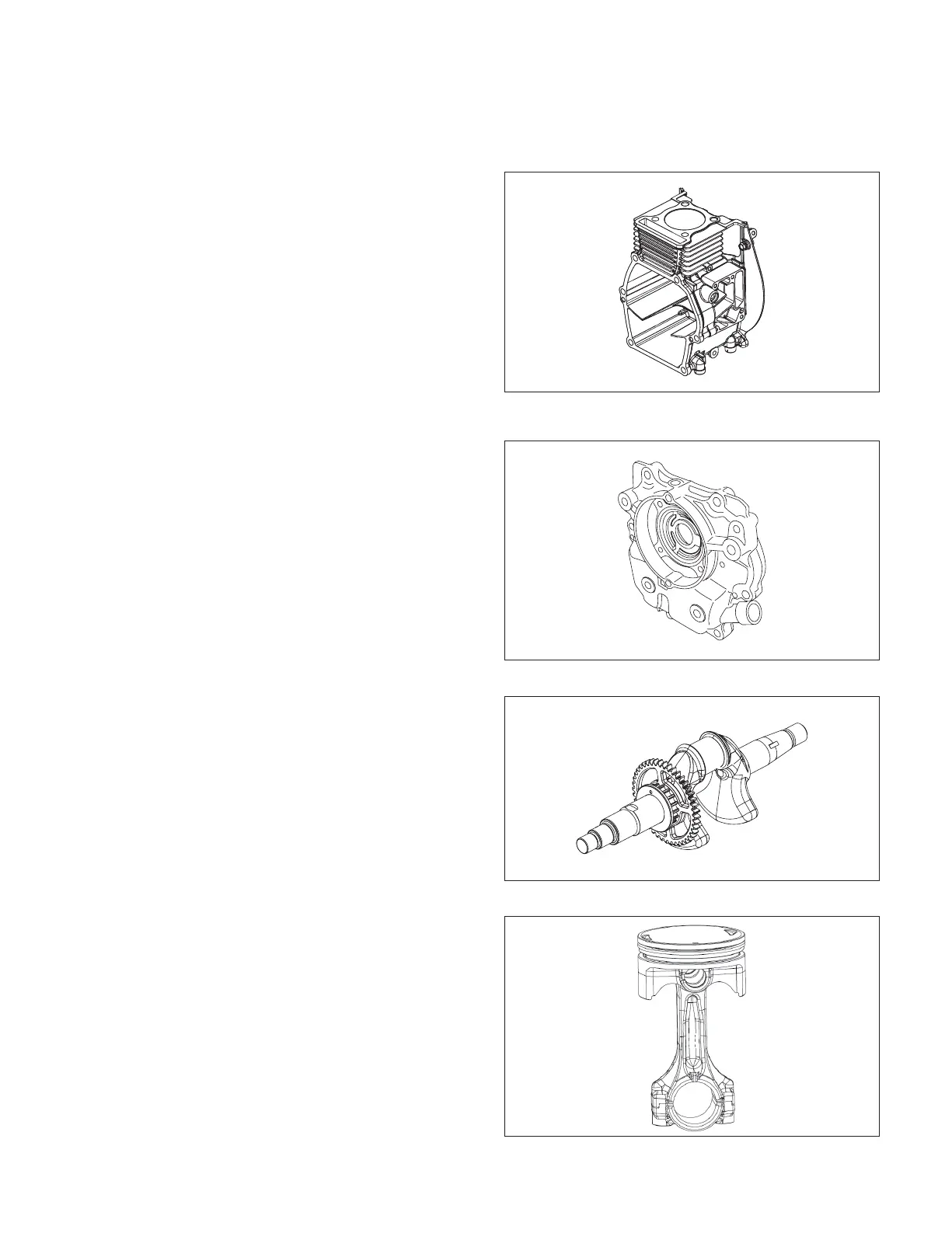

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS

4-1 CYLINDER AND CRANKCASE

The cylinder and crankcase are aluminum die-casting

as a single piece A special cast iron cylinder liner is

molded into the aluminum die-casting

The crankcase has a mounting surface on the output

shaft side to which the main bearing cover is attached

And the lib is made for the crankcase room center

cum oil shelter plate, that improvement breather

function and strength up

And inside of the crankcase has large rib for oil shelter

which to inprove the breather function and stiffness

4-2 MAIN BEARING COVER

The main bearing cover is an aluminum die-casting

with heavy-duty structure to endure to install on

rammers, which is mounted on the output shaft side of

the crankcase By removing the main bearing cover,

the inside of the engine can be inspected with ease

Pilots and bosses are machined into the cover for

direct mounting of the engine onto rammers

And it have suction pipe, oil pump, oil filter and oil

pressure switch

4-3 CRANKSHAFT

The crankshaft is forged carbon steel, and the crank

pin is high-frequency inductionhardened

The crank pulley used to drive the timing belt and the

gear used to drive the governor gear are pressed into

the output end of the shaft

4-4 CONNECTING ROD AND PISTON

The connecting rod is a specially heat-treated

aluminum alloy die-casting Its large and small ends

function as bearings The piston is an aluminum alloy

casting with grooves for mounting one compression

ring and one oil ring

JCC