22

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Malfunctions

Transport

Ensure that the machine is firmly lashed down and secured in the transport

vehicle.

Disposal

After becoming no longer fit for use, the machine and its accessories must be

disposed of in the correct manner in accordance with the national regulations.

On request, your TASKI partner can assist you with this.

Technical data

Malfunction Possible causes Troubleshooting page

Machine does not

run

No power supply

• Insert the plug into the

mains socket

Guide pillar in upright

position

• Place the machine in

the working position

20

Safety switch defect

• Call your Service Part-

ner

19

Machine cannot

be operated, but

the on light

shows

Machine has

overheated causing

motor protection

switch (trip) to cut in.

• Wait a while, try again

(the protection switch

will automatically re-

set)

Tool does not

rotate

Motor runs but not

tool

• Drive belt is torn or

lose

• Call your Service Part-

ner

Machine does not

reach rated

speed, motor

protection cuts in

Machine is

overloaded

• Check that you are

using the correct wor-

king technique

20

Insufficient voltage,

power cord is too long

• Remove extention

• Check power supply

voltage

Machine runs

uneasy

Tool deformed or

damaged

• Replace

Spray pump is

working, cleaning

solution is not

coming out

Cleaning solution has

dried up in spray unit

or tube is blocked

• Clean spray unit

• Replace

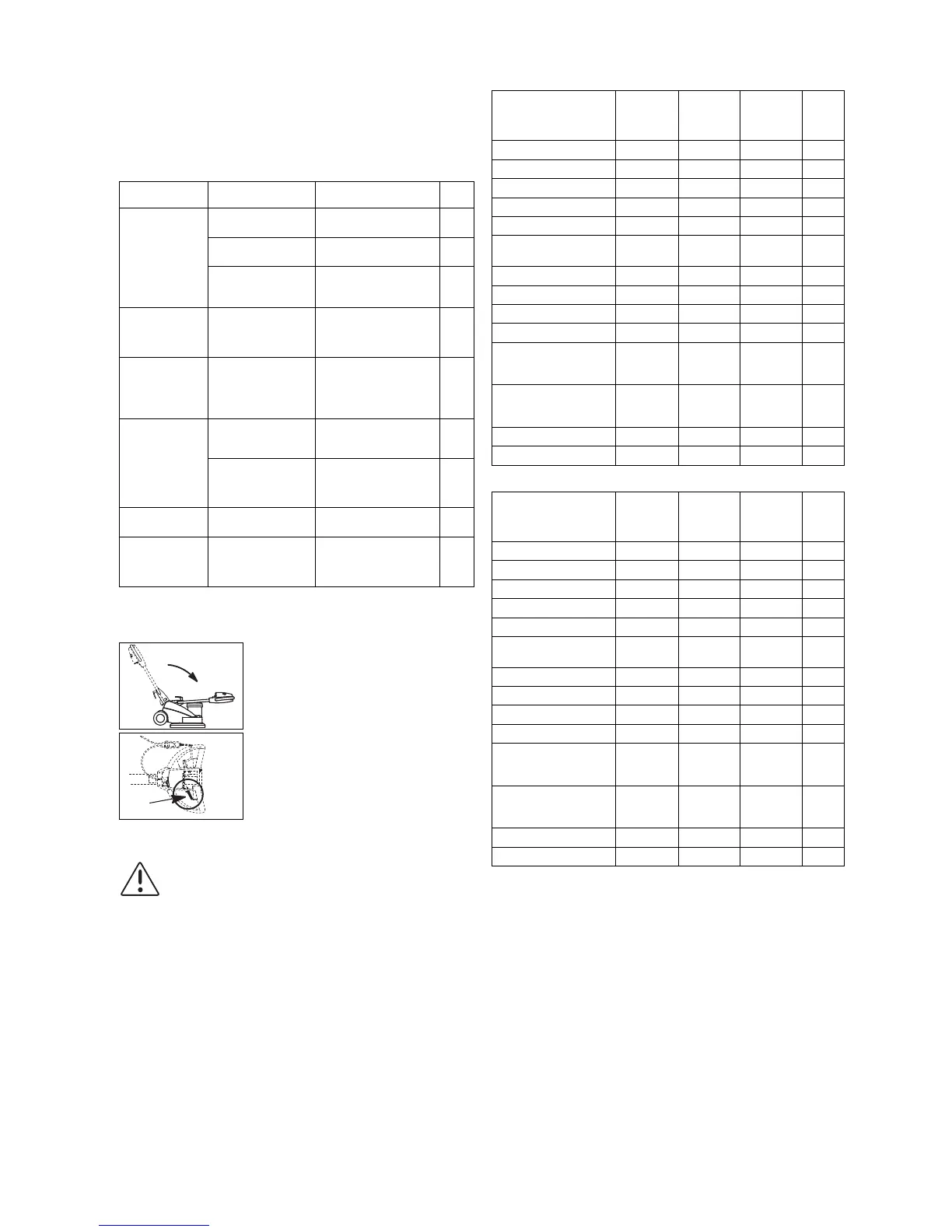

• Remove the tool (refer to Page 21).

• Pull the height adjustment lever and fold the

guide pillar towards the front.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• To lift the machine, one person must hold the tool unit and the other person

must hold the machine handle.

Caution:

The machine must always be carried by two persons and should

only be lifted by a single person in cases of emergency!

Machine 165 200 238

type 43DLS/

43DLSL

43LS/

43LSL

38LSL

Working width 43 43 38 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32 30.5 kg

Rated voltage 230-240V 230-240V 230-240V dc

Rated power 1100 800 800 W

Rated power (intergrated

socket)

700 -- -- W

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 165 165 165 min-1

Brush pressure 0.3 0.28 0.27 N/cm2

Assessed sound level

LPA according to EN

60704-1

57 57 57 dB(A)

The assessed effective

acceleration value

according to ISO 5349

0.4 0.4 0.4 m /s2

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

Machine 400 438 duo

type 43HS/

43HSL

38HSL 43LHS/

43LHSL

Working width 38 38 43 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32.5 47 kg

Rated voltage 230-240V 230-240V 230-240V dc

Rated power 1100 1100 1100 W

Rated power (intergrated

socket)

700 700 700 W

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 400 400 165/330 min-1

Brush pressure 0.3 0.28 0.4 N/cm2

Assessed sound level

LPA according to EN

60704-1

57 57 57 dB(A)

The assessed effective

acceleration value

according to ISO 5349

0.4 0.4 0.4 m /s2

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

Loading...

Loading...