Do you have a question about the TechnipFMC Smith Meter C2 and is the answer not in the manual?

| Model | C2 |

|---|---|

| Manufacturer | TechnipFMC |

| Category | Measuring Instruments |

| Type | Positive Displacement Flow Meter |

| Flow Range | Up to 1200 GPM (depending on meter size) |

| Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Output Options | Pulse, 4-20mA, Modbus |

| Material | Stainless Steel |

| Power Supply | 12-24 VDC |

Explains the positive displacement mechanism and double case design for ease of maintenance.

General advice and precautions for disassembly and cleaning of meter parts.

Lists essential tools and equipment required for meter disassembly.

Procedure for removing the standard pressure-outer cover on specific meter models.

Details on servicing the packing gland with glycerine solution for specific meter models.

Step-by-step guide for servicing and disassembling the high-pressure packing gland.

Instructions for removing the gear train components from the meter cover.

Description of the inner mechanism and its role in meter operation.

Procedure for adjusting rotor end clearance on C2 through G6 meter models.

Procedure for adjusting rotor end clearance on H8 and JA10 meter models.

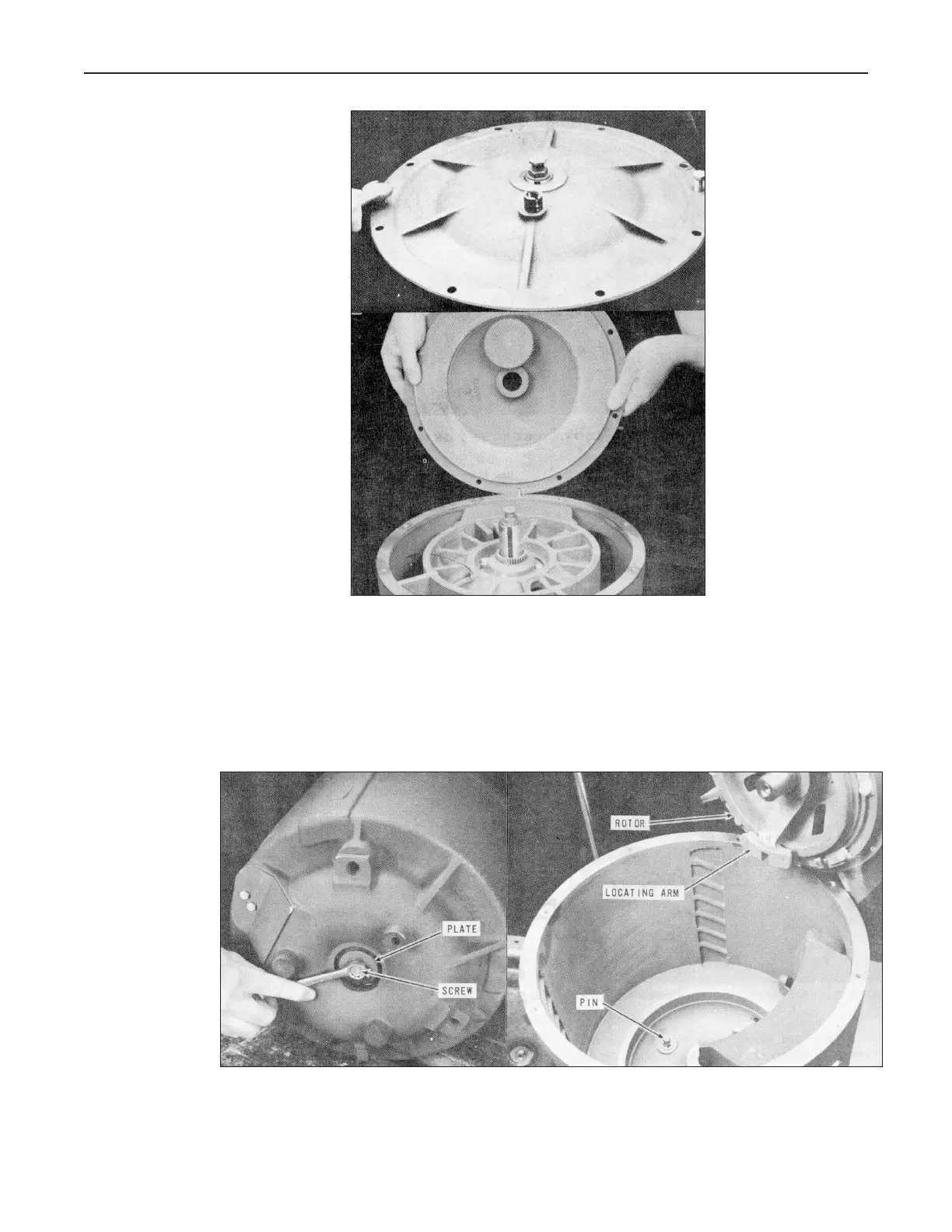

Steps for removing the inner mechanism from the meter housing.

Instructions for removing the rollers and pins from the rotor cover.

Details on the C2 series meter, including rotor spring positioning.

Lists recommended minimum and maximum fitting clearances for meter repair.

Guidance on checking meter clearances using feeler gauges.

Method for measuring blade slot clearance using feeler gauges.

Procedure for measuring blade top end clearance relative to the rotor.

Method for checking blade tip to housing clearance.

Procedure for measuring clearance between the rotor and block.

Method for measuring blade roller clearance against the cam radius.

Alternative method for measuring blade roller to cam radius difference.

Procedure for adjusting rotor and setting total end clearance.

Template for recording meter clearances found and after assembly.