Do you have a question about the Thermo King UT-Series and is the answer not in the manual?

| Application | Truck and trailer refrigeration |

|---|---|

| Refrigerant | R-404A |

| Capacity | Varies by model |

| Power Source | Diesel engine or electric standby |

| Dimensions | Varies by model |

| Weight | Varies by model |

Contact information for Thermo King's multi-lingual breakdown and repair assistance service.

Guidance for contacting local dealers for general inquiries and unit maintenance.

Basic safety practices for working with Thermo King units and safety stickers.

Information on the unit's automatic start/stop capability and safety precautions.

Safety warnings and precautions for battery installation and cable routing.

Safety warnings regarding handling fluorocarbon refrigerants and their properties.

Precautions for working with or around refrigerant oil, including protective gear.

First aid procedures for refrigerant and refrigerant oil exposure.

Information on the location and purpose of safety decals on the unit.

Decals near fans that can cause injury if clothing gets tangled.

Warning against using ether starting aids due to fire or explosion risk.

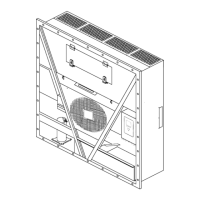

Overview of the UT-Series unit as a microprocessor-based transport temperature control system.

Details about the TK376 diesel engine, its power ratings, and belt drive system.

Information on Extended Life Coolant, its maintenance interval, and color.

Explanation of the centrifugal clutch's engagement and function during operation.

Details about the TKO Scroll 6.0 hp compressor used in UT-Series units.

Description of Standard and Premium HMI control panels for unit operation.

Explanation of the CYCLE-SENTRY fuel-saving system for optimum operating economy.

Process of melting frost on evaporator coils and defrost initiation methods.

Details on the optional Data Acquisition System for monitoring and recording temperatures.

Information on operating the unit using external electric power during standby.

Description of the electric power receptacle for connecting to an electric power source.

Features standard on units equipped with Electric Standby.

List of features available as an option on units equipped with Electric Standby.

Description of components found in the engine compartment.

Explanation of devices that protect the unit from damage.

Location and function of the engine oil pressure switch/sensor.

Function of the preheat buzzer during the CYCLE-SENTRY system's glow plug activation.

Role of the coolant temperature sensor in monitoring engine temperature.

How the overload relay protects the electric standby motor from overload.

Recommendations for pharmaceutical applications under Thermo King protocol.

Pretrip inspection procedures to minimize operating problems before each trip.

Instructions for checking belt condition and tension.

Guidance on checking electrical connections for security and integrity.

Visual inspection for leaks, loose parts, or damage to the unit.

Procedure for cleaning condenser and evaporator coils.

Inspection of the cargo box interior and exterior for damage.

Checking cargo doors and weather seals for proper condition and fit.

Inspection of defrost drain hoses to ensure they are open.

Visual inspection of remote evaporators and defrost initiation check.

Operating the unit using the Premium HMI controller and accessing menus.

Details of the Premium HMI control panel display and its hard keys.

Features of the HMI controller for displaying information and changing settings.

Description of hard keys and soft keys on the HMI control panel.

Reference to resources for operating the TSR-3 controller and diagnosing alarms.

Explanation of how alarm codes are generated and their purpose.

Procedures for inspecting the unit and cargo before loading.

Visual guide to loading considerations for optimal temperature management.

Procedures to ensure the cargo has been loaded properly after loading.

Procedures for performing enroute inspections to minimize temperature issues.

Remedies for common problems encountered during return air temperature readings.

Troubleshooting for improper air circulation and unit start failures.

Technical specifications for the Thermo King TK 376U diesel engine, including fuel and oil types.

Recommended oil viscosity based on ambient temperature and engine RPM specifications.

Details on engine coolant types and coolant system capacity.

List of fuses, their sizes, and functions within the unit's electrical system.

Specifications for the unit's electrical system, including voltage and battery details.

Requirements for standby power, including circuit breakers and extension cord size.

Guidance to contact Thermo King dealer for refrigeration system service or maintenance.

Determining inspection and service intervals based on operating hours and unit age.

Key items to inspect and service during a pretrip check.

Instructions on recording inspection and service performed on the dealer service record.