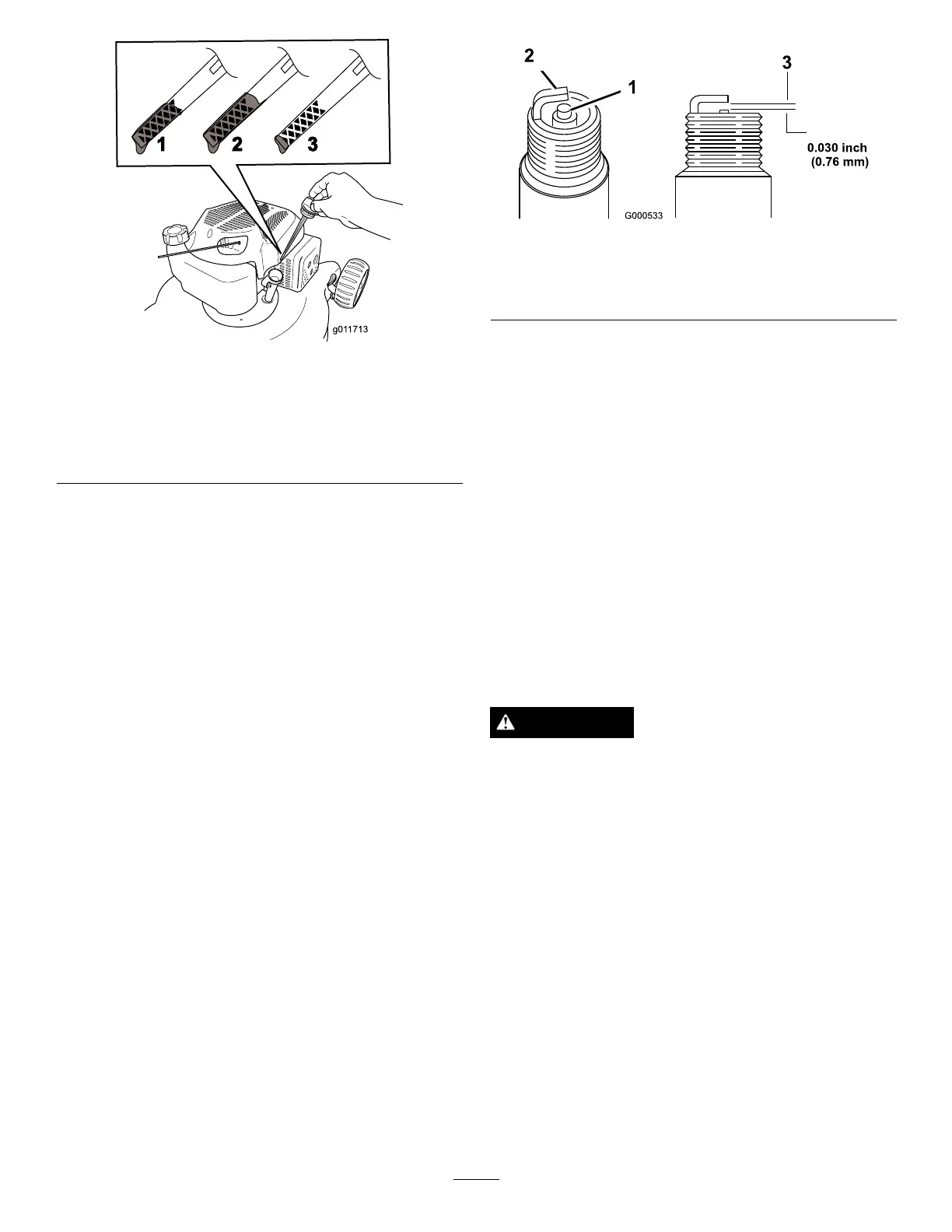

Figure22

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

8.Installthedipstickandhandtightenitsecurely.

9.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Checkthesparkplugafterevery100operatinghours.

UseanChampionRN9YCsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

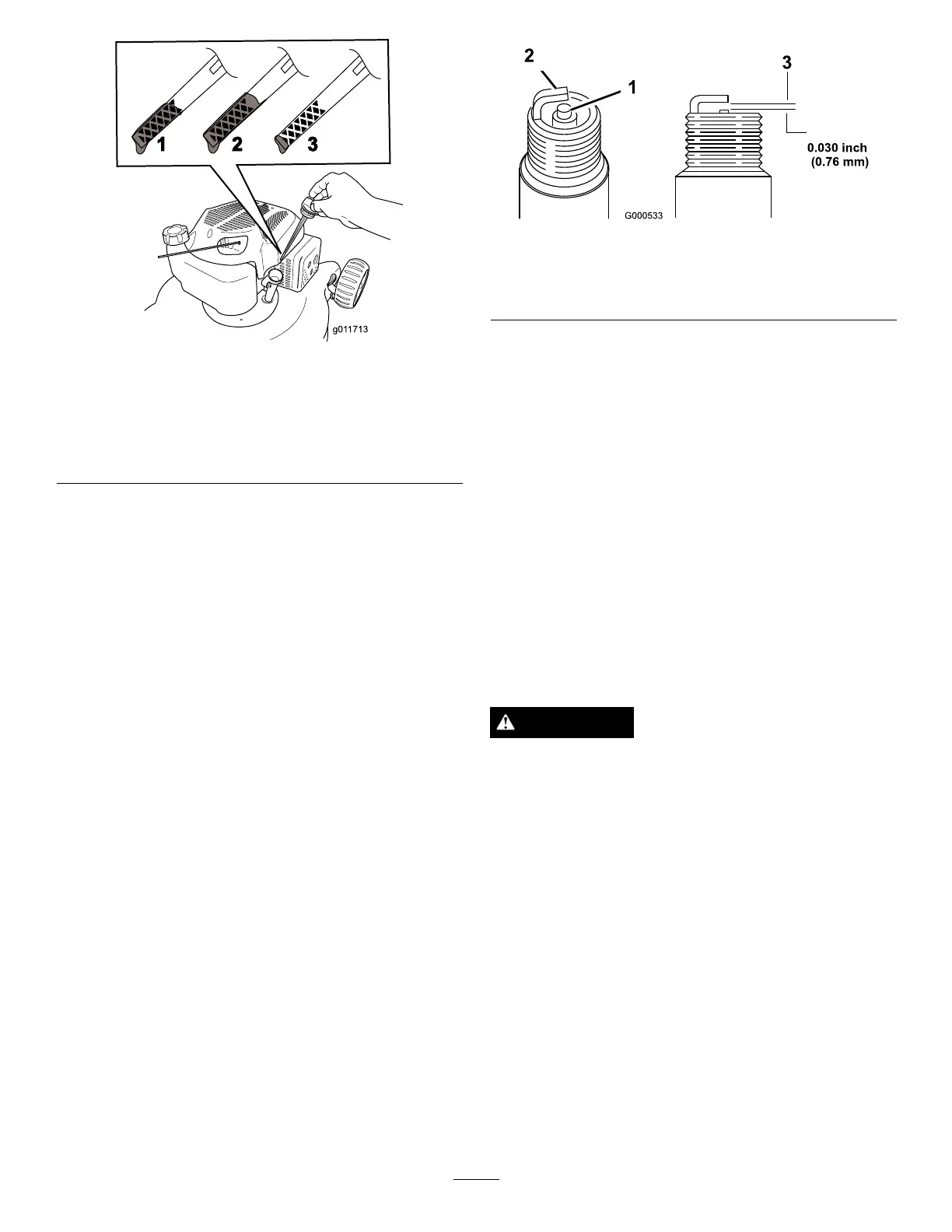

5.Setthegapontheplugto0.030inch(0.76mm)

(

Figure23).

Figure23

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto15ft-lb(20N-m).

8.Connectthewiretothesparkplug.

ReplacingtheBlade

ServiceInterval:Yearly

Important:

Y ou will need a torque wr ench to install

the blade pr oper l y

.Ifyoudonothaveatorque

wrenchorareuncomfortableperformingthis

procedure,contactanAuthorizedServiceDealer.

Examinethebladewheneveryourunoutofgasoline.If

thebladeisdamagedorcracked,replaceitimmediately.

Ifthebladeedgeisdullornicked,haveitsharpenedor

replaceit.

WARNING

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

•Disconnectthewirefromthesparkplug.

•Weargloveswhenservicingtheblade.

1.Disconnectthesparkplugwirefromthesparkplug.

RefertoPreparingforMaintenance.

2.Tipthemowerontoitsside,withtheairlterup.

3.Useablockofwoodtoholdthebladesteady.

4.Removetheblade(turnthebladebolt

counterclockwise),savingallthemountinghardware.

5.Installthenewblade(turnthebladeboltclockwise)

andallmountinghardware(

Figure24).

12

Loading...

Loading...