Note:Max.ll:0.55L(0.58qtor18.6oz),type:SAE

30detergentoilwithanAPIserviceclassicationof

SF,SG,SH,SJ,SL,orhigher.

7.Waitabout3minutesfortheoiltosettleinthe

crankcase.

8.Wipethedipstickcleanwithacleancloth.

9.Insertthedipstickintotheoil-lltube(butdonot

screwitin),thenremovethedipstick.

10.Readtheoillevelonthedipstick(Figure20).

•Iftheoillevelislow ,slowlypourasmallamountof

oilintotheoil-lltubeandrepeatsteps8through

10untiltheoillevelonthedipstickiscorrect.

•Iftheoillevelishigh,draintheexcessoiluntilthe

oillevelonthedipstickiscorrect.

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

11.Installthedipsticksecurely.

12.Recycletheusedoilproperly.

ReplacingtheBlade

ServiceInterval:Yearly

Important:

Y ou will need a torque wr ench to install the

blade pr oper l y

.Ifyoudonothaveatorquewrenchor

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladewheneveryourunoutofgasoline.Ifthe

bladeisdamagedorcracked,replaceitimmediately.Ifthe

bladeedgeisdullornicked,haveitsharpenedandbalanced,

orreplaceit.

WARNING

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

Weargloveswhenservicingtheblade.

1.RefertoPreparingforMaintenance(page13).

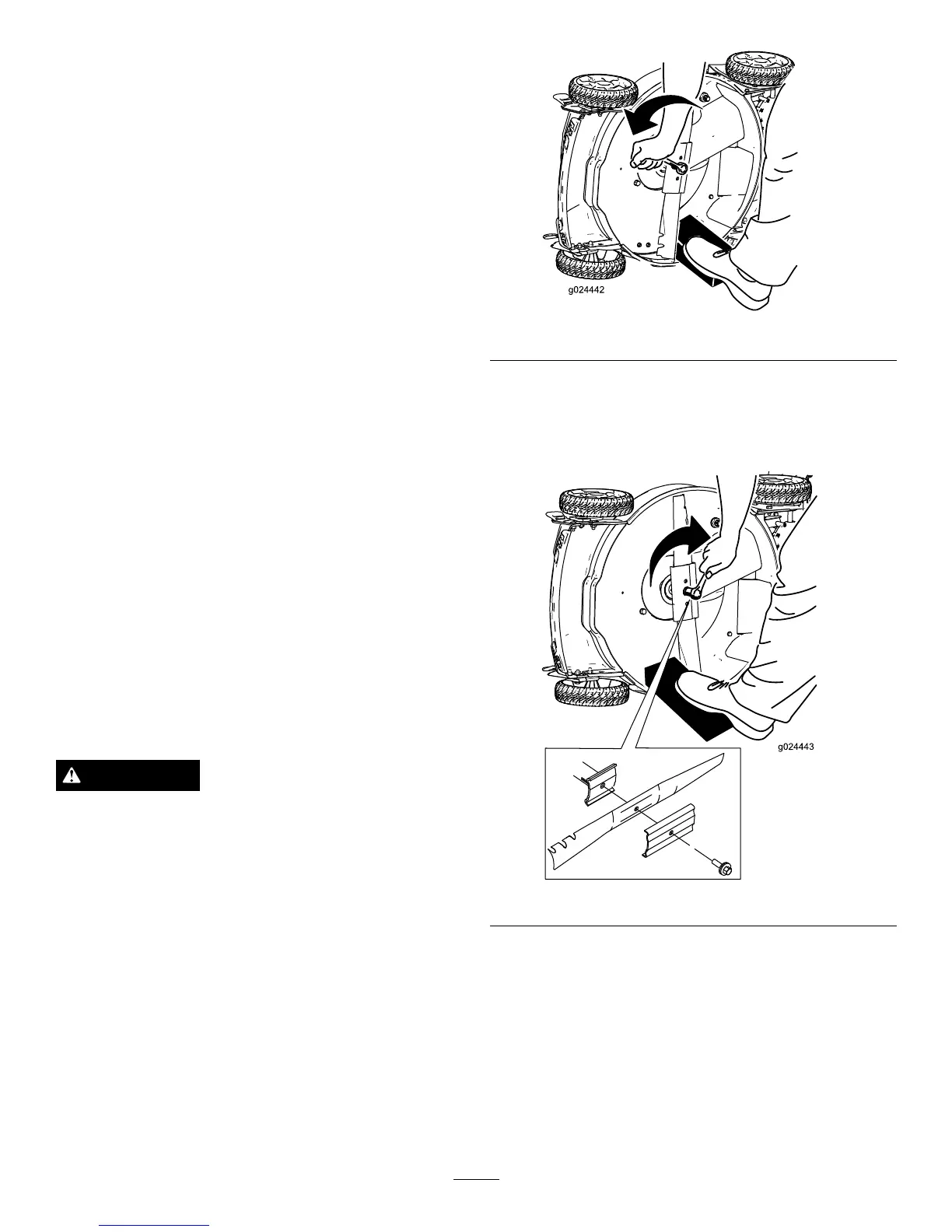

2.Tipthemachineeitherontoitssidewiththedipstick

down.

3.Useablockofwoodtoholdthebladesteady(Figure

22).

Figure22

4.Removetheblade,savingallmountinghardware

(Figure22).

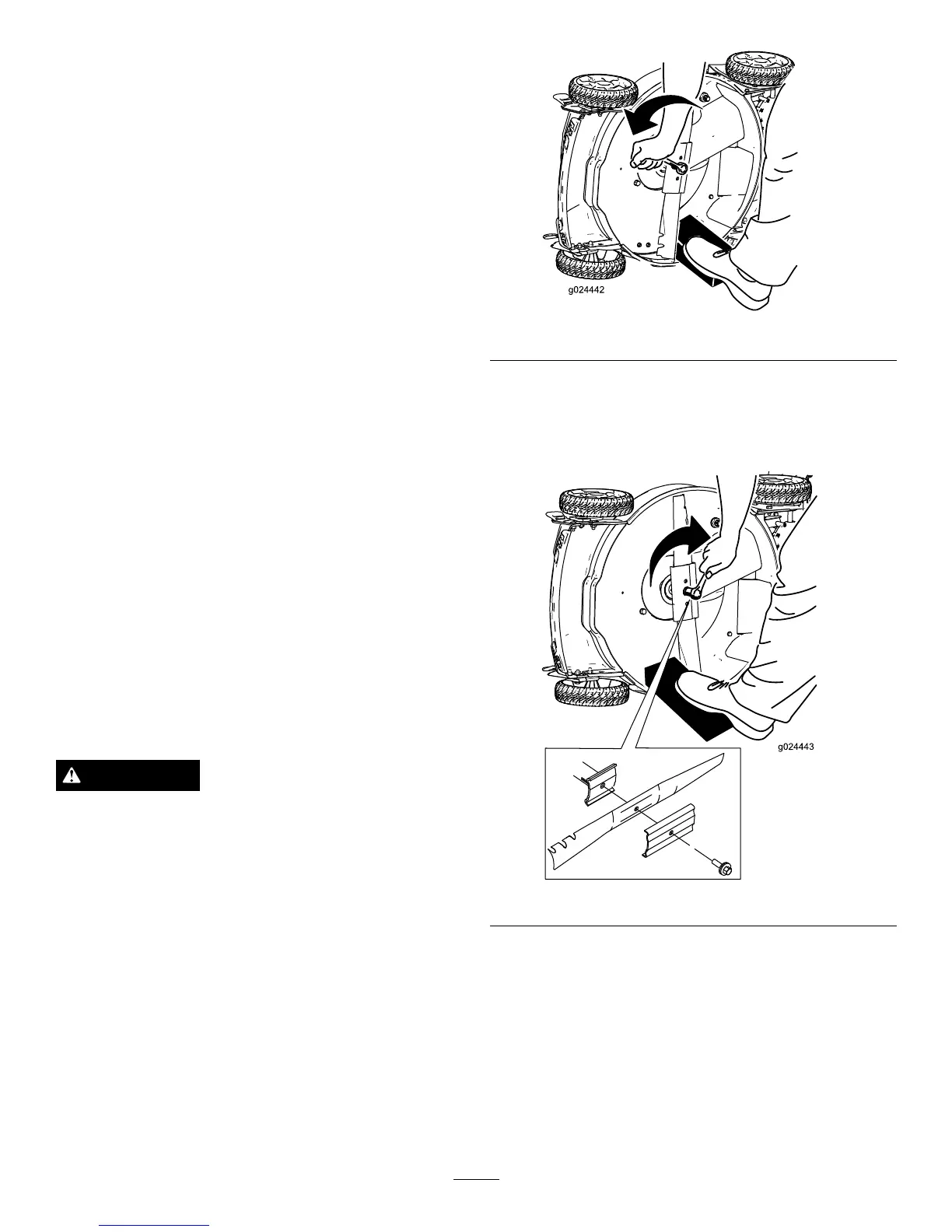

5.Installthenewbladeandallmountinghardware

(Figure23).

Figure23

Important:Positionthecurvedendsoftheblade

topointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladeboltto

82N-m(60ft-lb).

Important:Abolttorquedto82N-m(60ft-lb)is

verytight.Whileholdingthebladewithablock

ofwood,putyourweightbehindtheratchetor

wrenchandtightentheboltsecurely.Thisboltis

verydifculttoovertighten.

15

Loading...

Loading...