Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

Aftertherst2hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevelandaddoilifnecessary.

Yearly

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Checkthesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

Yearlyorbeforestorage

•Preparethemachineforstorage.

MaintenanceSafety

Readthefollowingsafetyprecautionsbeforeperformingany

maintenanceonthemachine:

•Beforeperforminganymaintenance,service,or

adjustment,shutofftheengineandremovethekey.If

majorrepairsareeverneeded,contactanAuthorized

ServiceDealer.

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

AdjustingtheControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Checkthecontrol

cableandadjustitifnecessary.

Yearly—Checkthecontrolcableandadjustitif

necessary.

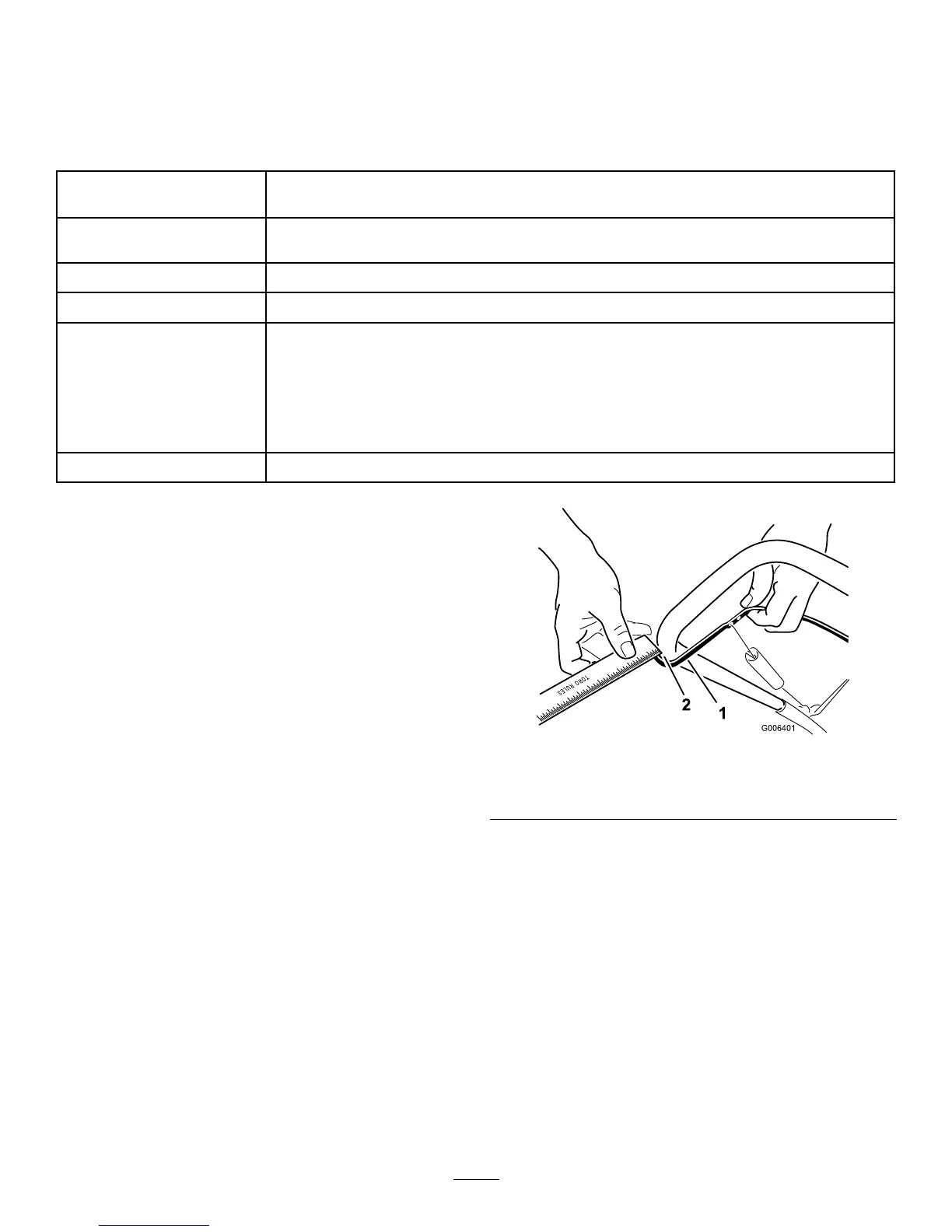

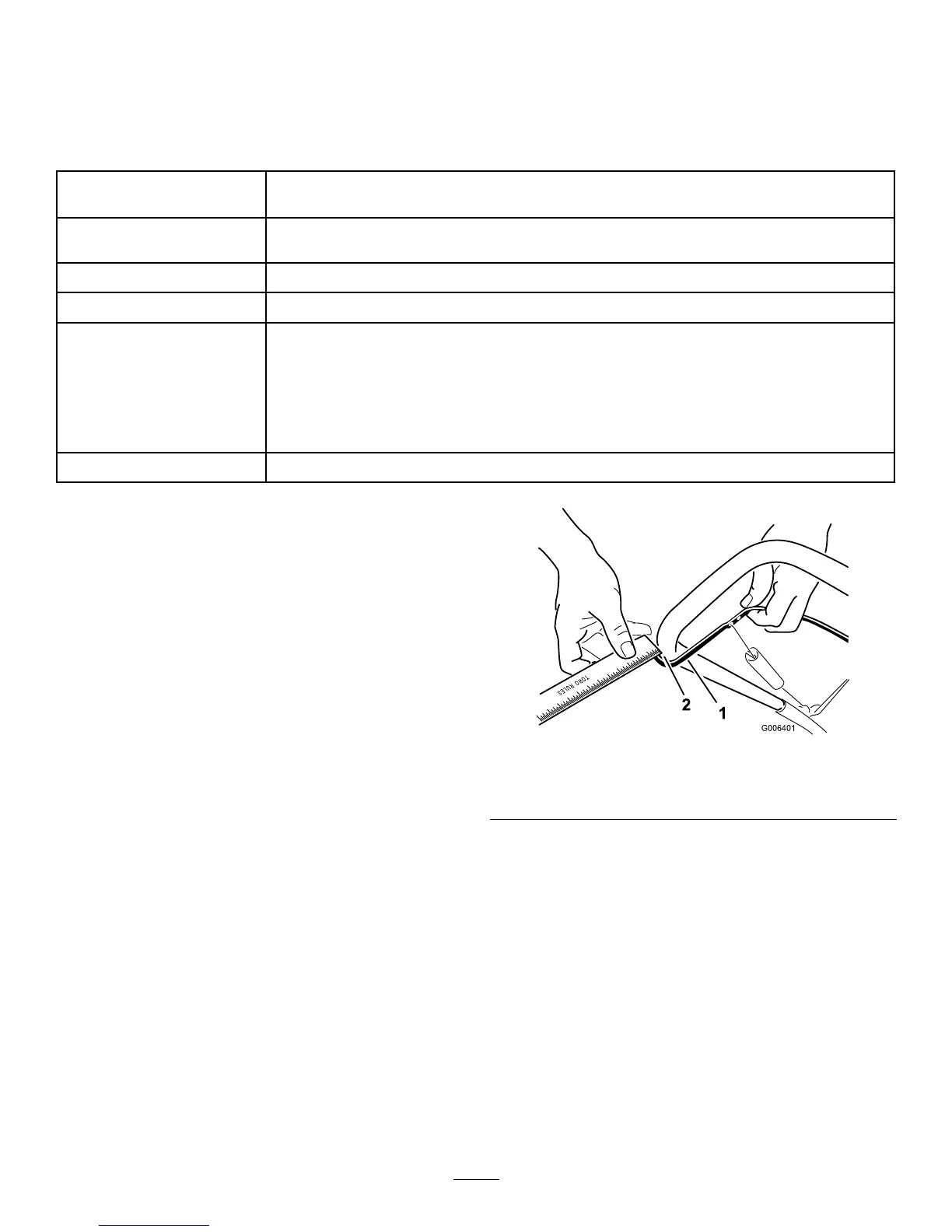

Movethecontrolbarbacktowardthehandletoremovethe

slackinthecontrolcable(Figure25).

Figure25

1.Controlbar2.2mmto3mm(1/16inch

to1/8inch)gap

Note:Ensurethata2mmto3mm(1/16inchto1/8inch)

gapexistsbetweenthecontrolbarandthehandle(Figure25).

Important:Thecontrolcablemustcontainsomeslack

whenyoudisengagethecontrolbarfortherotorblades

tostopproperly.

12

Loading...

Loading...