Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

Aftertherst2hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevelandaddoilifnecessary.

Yearly

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Servicethesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

Yearlyorbeforestorage

•Preparethemachineforstorage.

AdjustingtheControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Check

thecontrolcableandadjustitif

necessary.

Yearly—Checkthecontrolcableand

adjustitifnecessary.

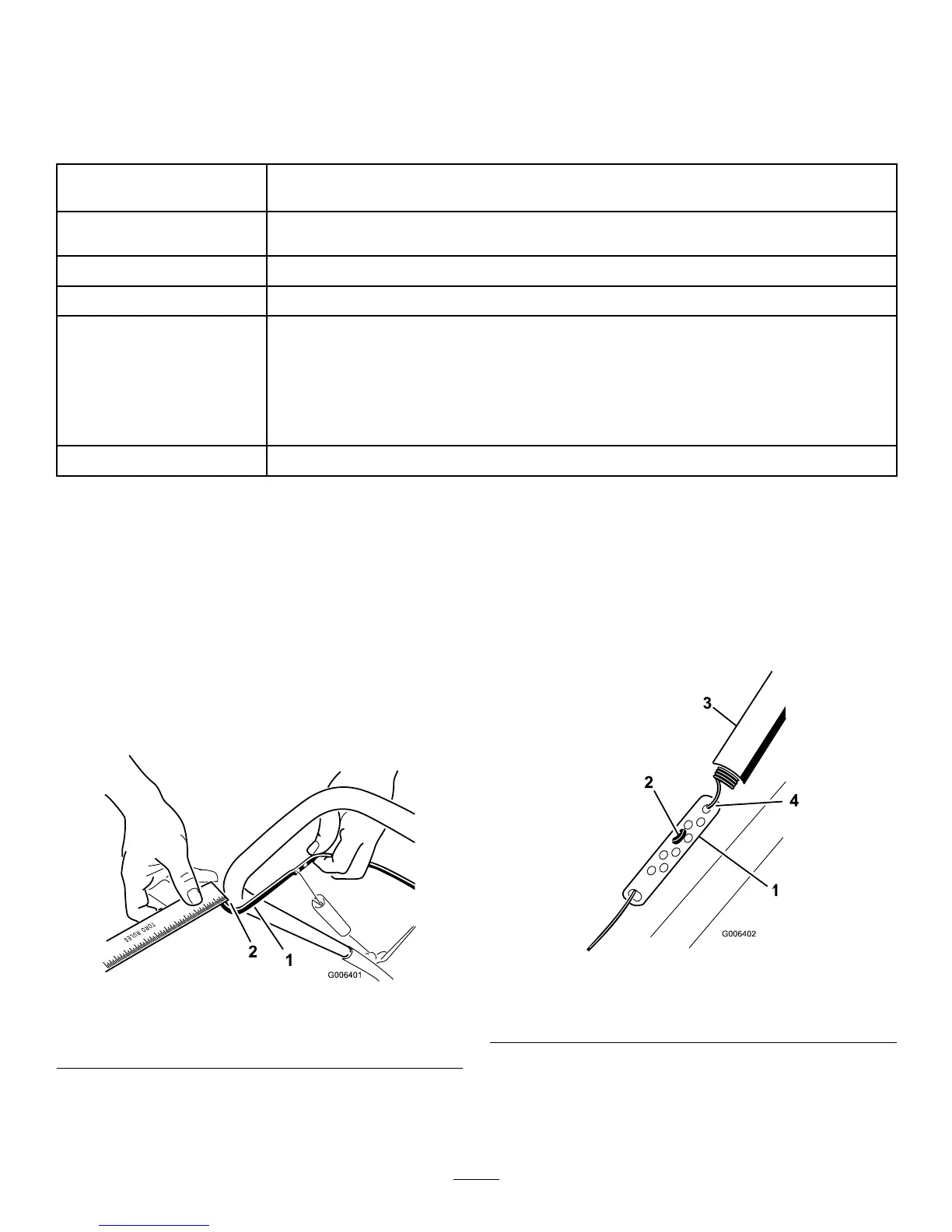

Movethecontrolbarbacktowardthehandletoremove

theslackinthecontrolcable(

Figure24).

Figure24

1.Controlbar2.1/16-inchto1/8-inch(2

mmto3mm)gap

Note:Ensurethata1/16-inchto1/8-inch(2mmto3

mm)gapexistsbetweenthecontrolbarandthehandle

(Figure24).

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

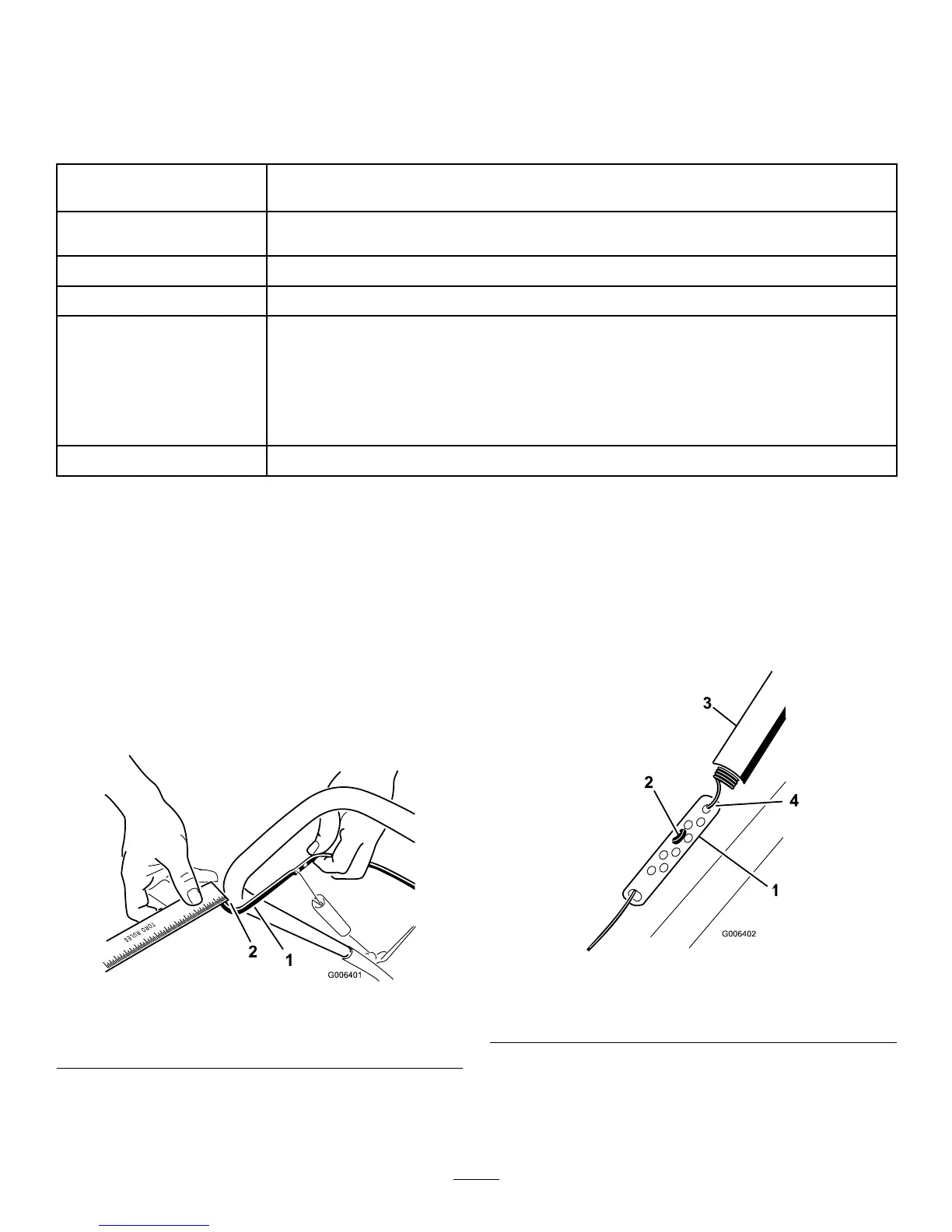

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespring

fromtheadjusterlink(

Figure25).

Figure25

1.Adjusterlink

3.Springcover

2.Z-tting

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe1/16-inchto

12

Loading...

Loading...