Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Checkthecontrolcableandadjustitifnecessary.

Aftertherst2hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevelandaddoilifnecessary.

Every100hours

•Replacethesparkplug.

Yearly

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineT ororeplacementparts

andaccessories.

CheckingandAdjustingthe

ControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Checkthe

controlcableandadjustitif

necessary.

Yearly—Checkthecontrolcableandadjustit

ifnecessary.

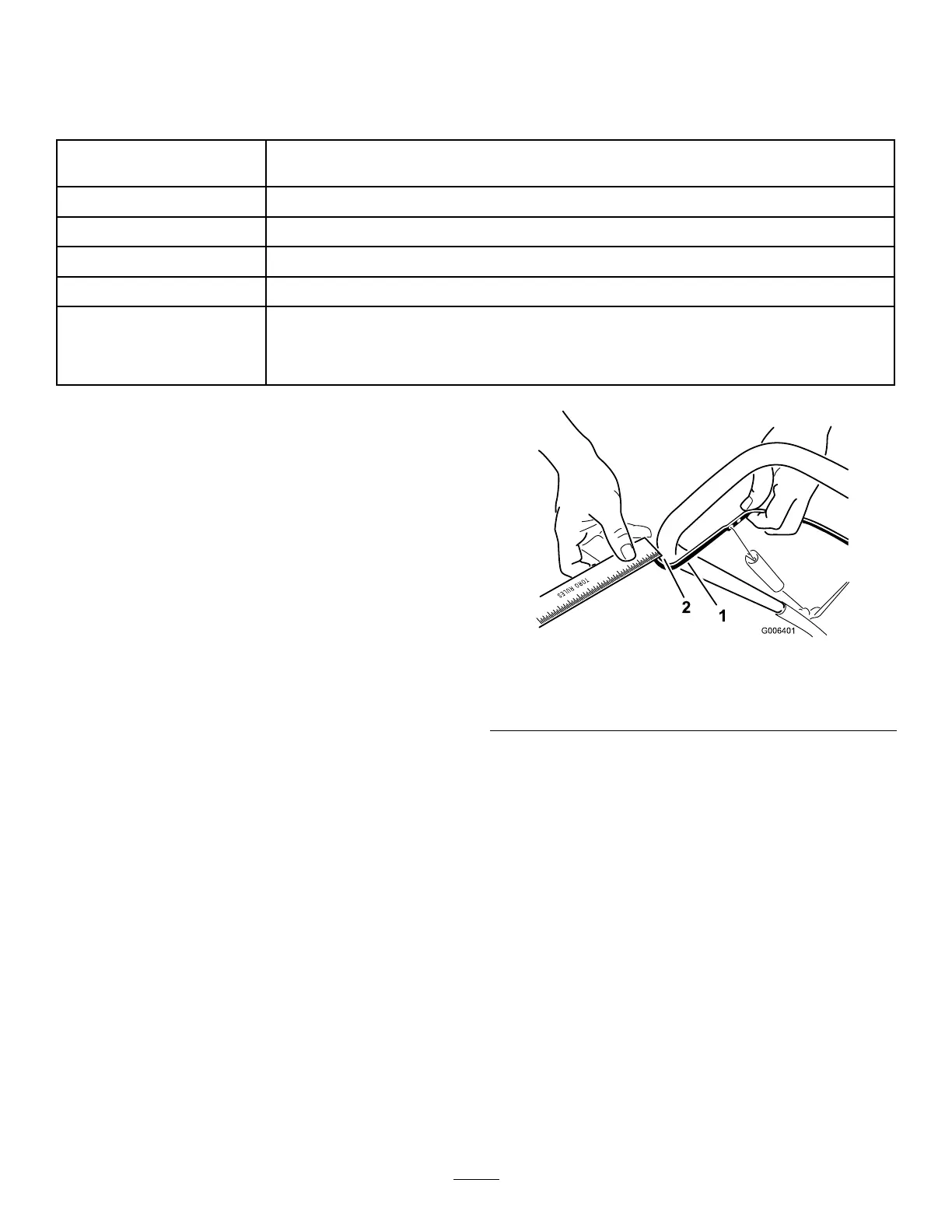

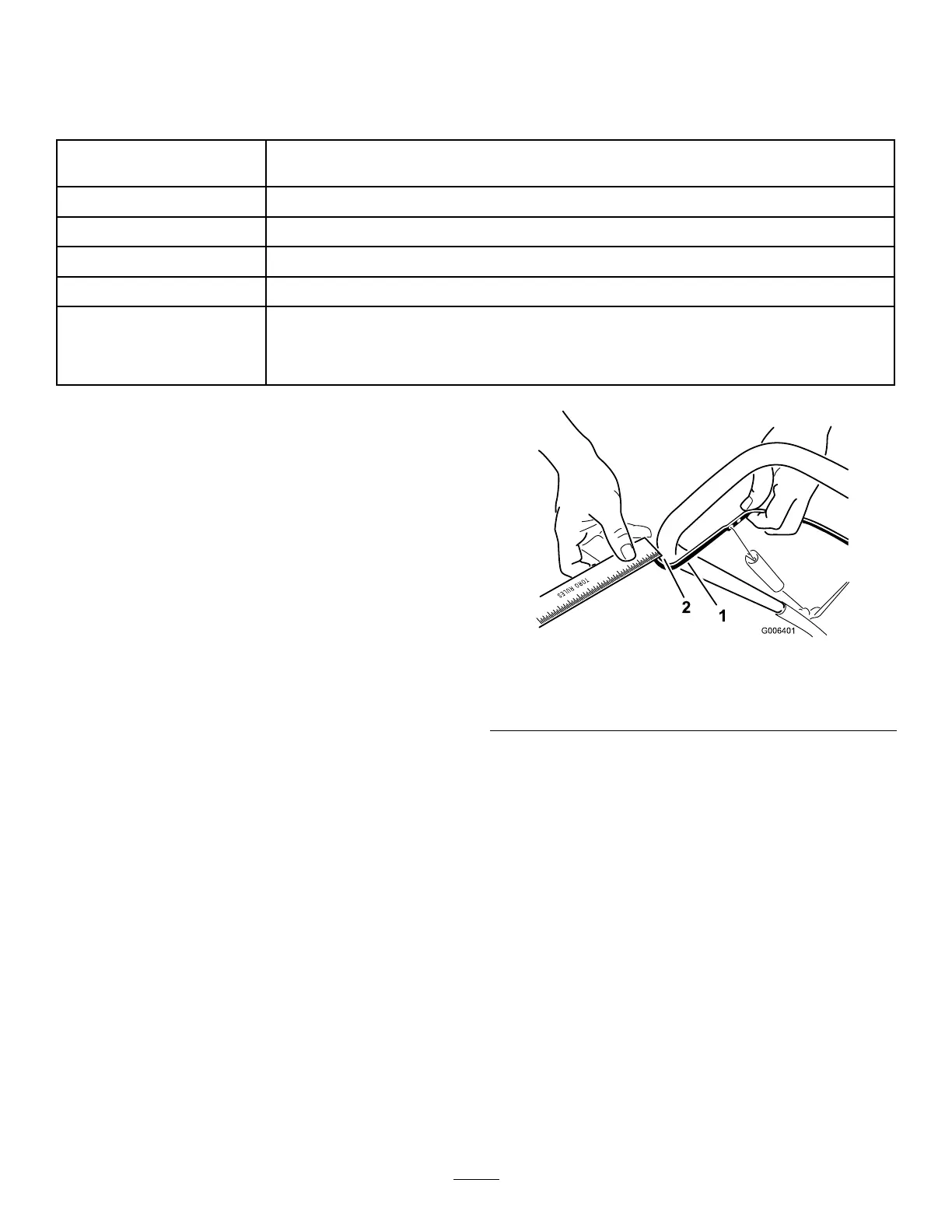

Movethecontrolbarbacktowardthehandleto

removetheslackinthecontrolcable(Figure16).

g006401

Figure16

1.Controlbar2.2mmto3mm(1/16inch

to1/8inch)gap

Note:Ensurethata2to3mm(1/16to1/8inch)

gapexistsbetweenthecontrolbarandthehandle

(Figure16).

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

14

Loading...

Loading...