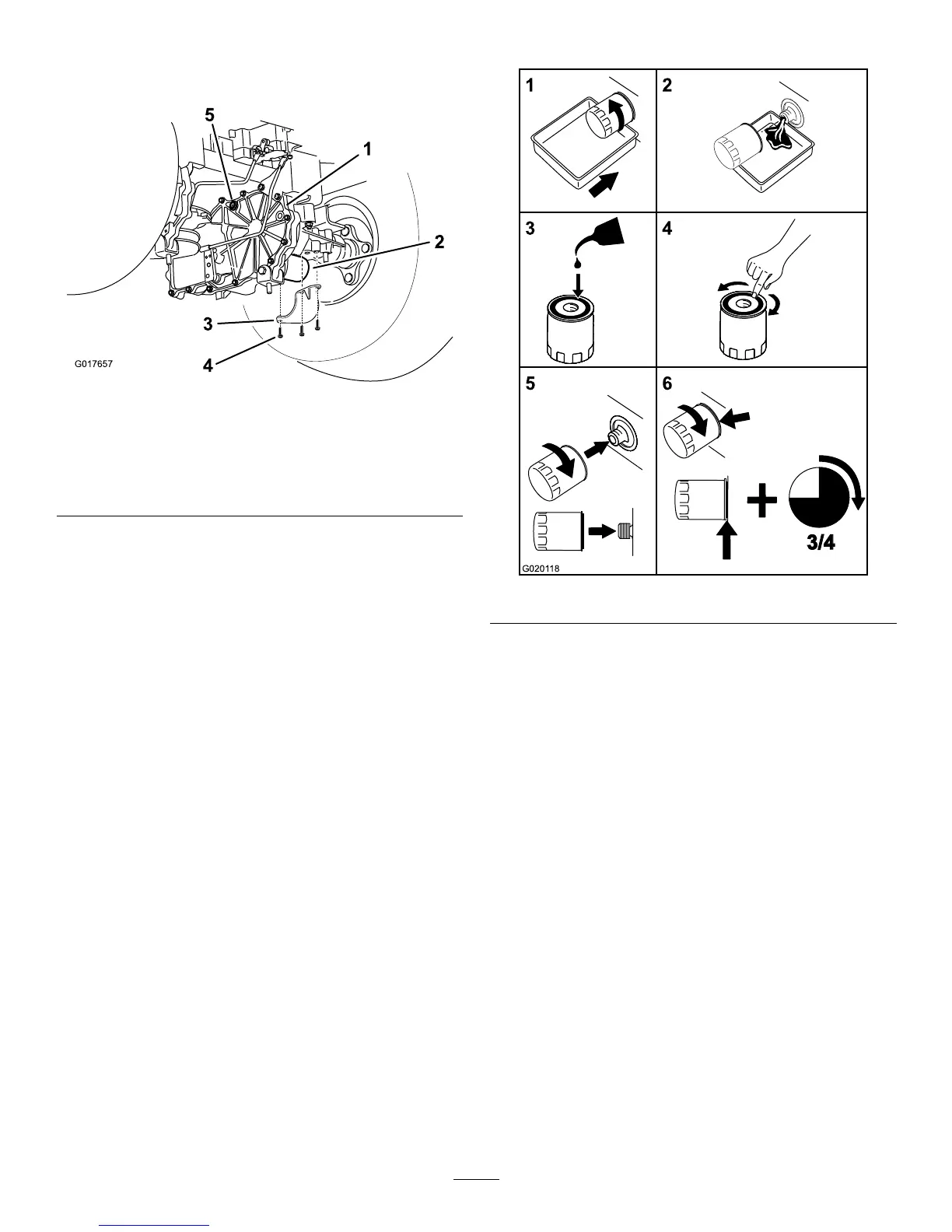

Figure46

Rightsideshown

1.Transaxledrive

4.Screws

2.Oillter

5.Ventplug

3.Filterguard

5.Carefullycleanareaaroundlters.Itisimportantthat

nodirtorcontaminationenterhydraulicsystem.

6.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterandventplugsareremoved.

7.Locateandremovetheventplugoneachtransmission

8.Unscrewtheltertoremoveandallowoiltodrain

fromdrivesystem.

Repeatthisprocedureforbothlters.

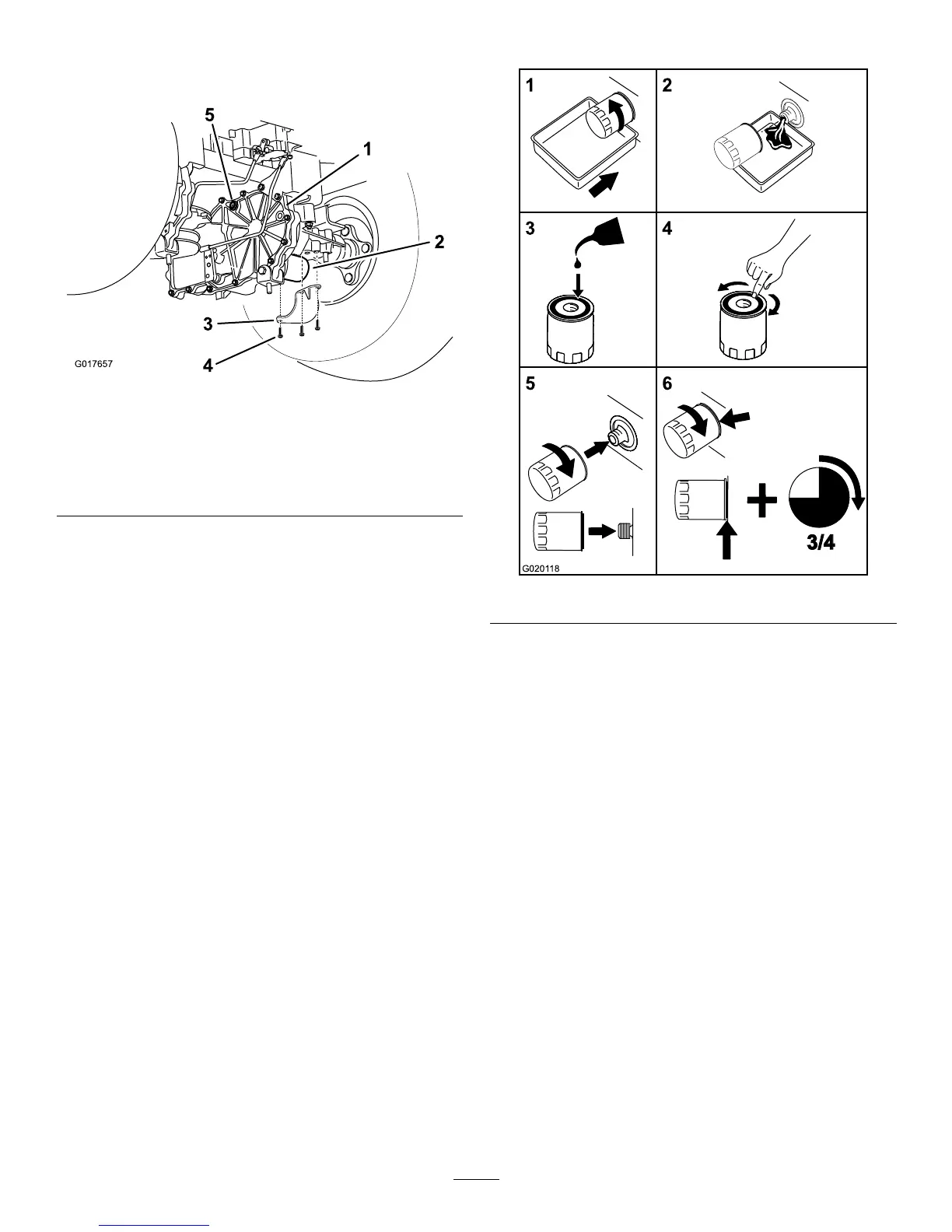

InstallingtheHydraulicSystemFilters

Figure47

1.Applyathincoatofthespeciedoilonthesurfaceof

therubbersealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4to

1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Installthetransaxlesupport.RefertoFigure45forthe

correcttorquevaluesforthenutsandbolts.

Note:Ensurethetransaxlesupportisinstalled(

Figure

45).

5.Verifytheventplugsareremovedbeforeaddingtheoil.

6.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.Stopandinstallthatventplug.Torquetheplug

to180in-lb(20.3N-m).

7.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.Stopandinstallthatvent

plug.Torquetheplugto180in-lb(20.3N-m).

8.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineontheexpansion

reservoir.

35

Loading...

Loading...