ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

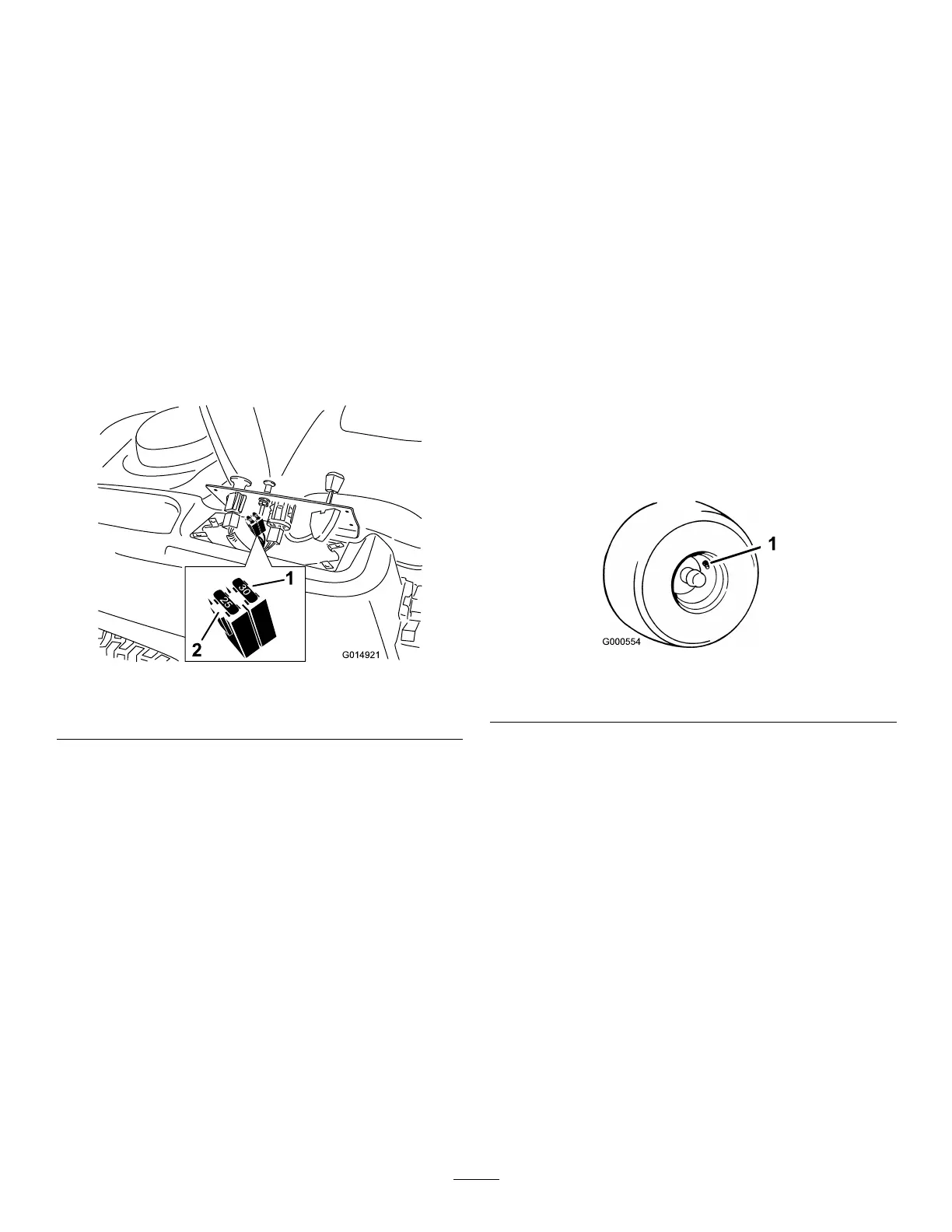

1.Removethescrewssecuringthecontrolpanel

tothemachine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwire

harnessandfuseblock(Figure49).

3.Toreplaceafuse,pulloutthefusetoremove

it(Figure49).

g014921

Figure49

1.Main(30A)2.Chargecircuit(25A)

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslyto

securethepaneltothemachine.

DriveSystem

Maintenance

CheckingtheTirePressure

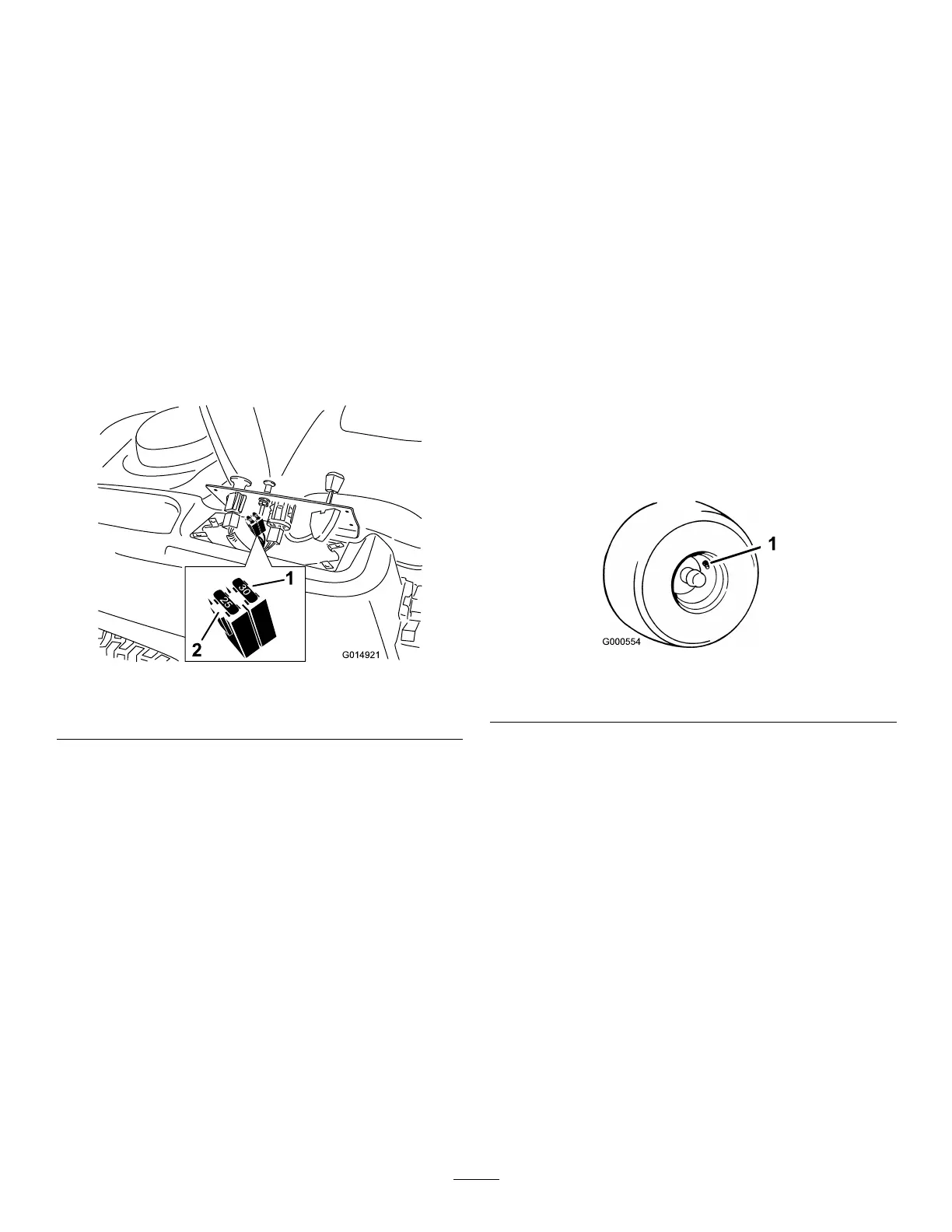

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure50).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Formachineswith42-inchor50-inchdecks,inate

thereardrivewheeltiresto90kPa(13psi).

Formachineswith54-inchor60-inchdecks,inate

thefrontcastersandreardrivewheeltiresto103kPa

(15psi).

g000554

Figure50

1.Valvestem

44

Loading...

Loading...