BleedingtheHydraulic

System

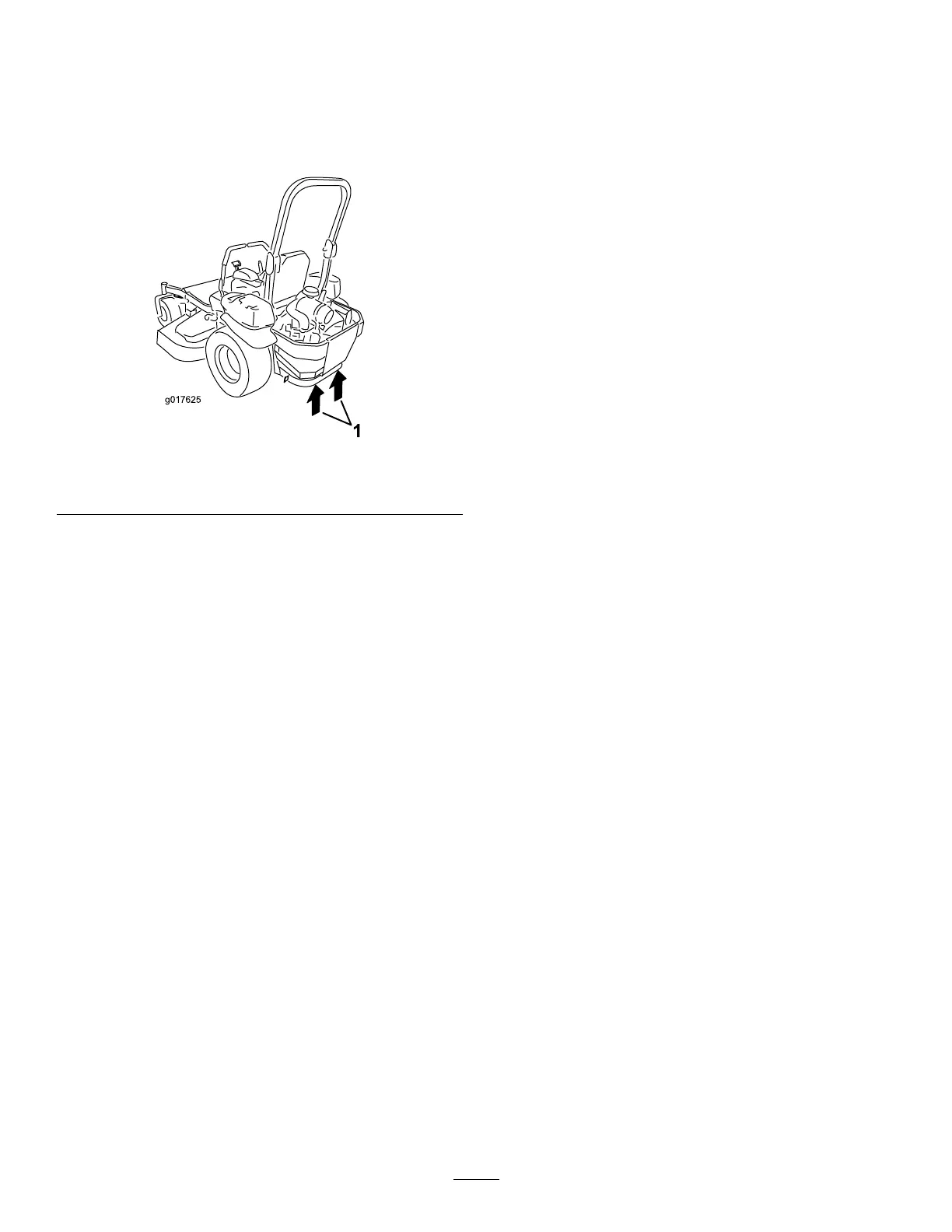

1.Raisetherearofmachineandsupportitwith

jackstands(orequivalentsupport)justhigh

enoughtoallowthedrivewheelstoturnfreely.

g017625

Figure63

1.Jackingpoints

2.Starttheengine,movethethrottlecontrolahead

tothe1/2throttleposition,anddisengagethe

parkingbrake.

A.Movethebypassleversintothepushingthe

machineposition.Withthebypassvalves

openandtheenginerunning,slowlymove

themotion-controlleversinbothforward

andreverse5or6times.

B.Movethebypassleversintotheoperating

themachineposition.

C.Withthebypassvalveclosedandthe

enginerunning,slowlymovethecontrol

leverinbothforwardandreversedirections

5to6times.

D.Shutofftheengineandchecktheuid

levelintheexpansionreservoir.Addthe

specieduiduntilitreachestheFULLCOLD

lineontheexpansionreservoir.

3.Repeatstep2untilalltheairiscompletely

purgedfromthesystem.

Note:Whenthetransaxleoperatesatnormal

noiselevels,movessmoothlyforward,and

reversesatnormalspeeds,itispurged.

4.Checktheuidlevelintheexpansionreservoir

analtime.Addthespecieduidasuntilit

reachestheFULLCOLDlineontheexpansion

reservoir.

MowerDeck

Maintenance

BladeSafety

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating

onebladecancauseotherbladestorotate.

•Replacewornordamagedbladesandboltsinsets

topreservebalance.

ServicingtheCutting

Blades

BeforeInspectingorServicingthe

Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure64).

2.Iftheedgesarenotsharporhavenicks,remove

andsharpentheblade;refertoSharpeningthe

Blades(page53).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforming

inthisarea,immediatelyinstallanewblade

(Figure64).

51

Loading...

Loading...