10

18-BC98D1-1G-EN

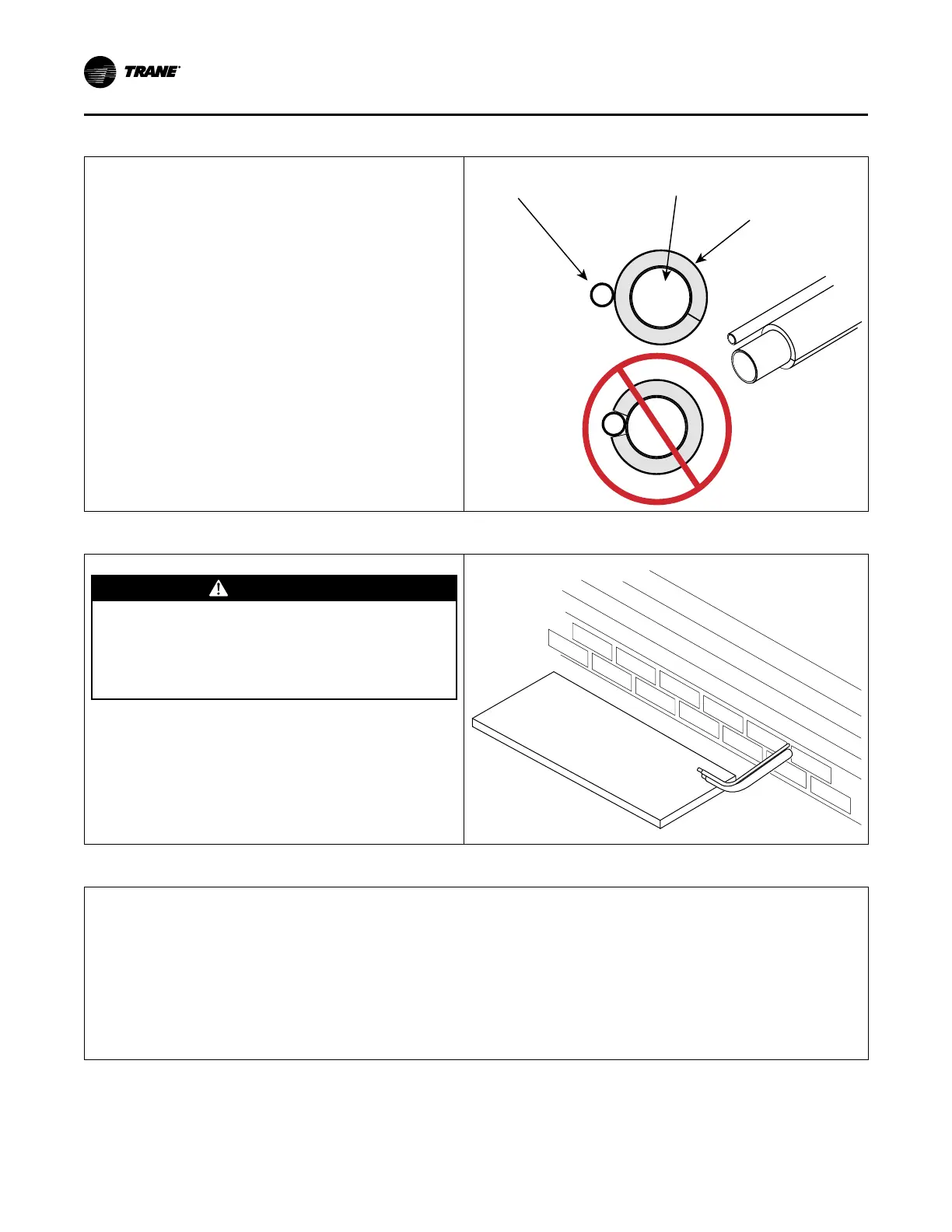

Table 10. Refrigerant Line Insulation

Important: The Vapor Line must always be insulated. DO NOT

allow the Liquid Line and Vapor Line to come in direct

(metal to metal) contact.

Note: The gas line must always be insulated. Insulating the liquid

line through attic spaces may benefit system performance by

minimizing heat gain in the liquid line.

Liquid Line

Vapor Line

Insulation

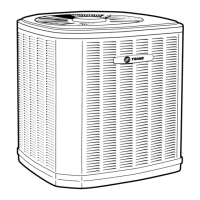

Table 11. Reuse Existing Refrigerant Lines

CCAAUUTTIIOONN

RREEFFRRIIGGEERRAANNTT!!

FFaaiilluurree ttoo iinnssppeecctt oorr uussee pprrooppeerr sseerrvviiccee ttoooollss mmaayy

rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

IIff uussiinngg eexxiissttiinngg rreeffrriiggeerraanntt lliinneess mmaakkee cceerrttaaiinn tthhaatt

aallll jjooiinnttss aarree bbrraazzeedd,, nnoott ssoollddeerreedd..

For retrofit applications, where the existing indoor evaporator coil

and/or refrigerant lines will be used, the following precautions

should be taken.

• Ensure that the indoor evaporator coil and refrigerant lines are

the correct size.

• Ensure that the refrigerant lines are free of leaks, acid, and oil.

Important: For more information, see publication number SS-

APG006–EN

Table 12. Refrigerant Line Routing Precautions

Important: Comply with National, State, and Local Codes when isolating line sets from joists, rafters, walls, or other structural elements.

Important: Take precautions to prevent noise within the building structure due to vibration transmission from the refrigerant lines.

For Example:

• When the refrigerant lines must be fastened to floor joists or other framing in a structure, use isolation type hangers.

• Isolation hangers should also be used when refrigerant lines are run in stud spaces or enclosed ceilings.

• Where the refrigerant lines run through a wall or sill, they should be insulated and isolated.

• Isolate the lines from all duct work.

• Minimize the number of 90° turns.

UUnniitt LLooccaattiioonn CCoonnssiiddeerraattiioonnss

Loading...

Loading...