16 18-AC124D1-1A-EN

STEP 6 - Adjust refrigerant level to attain proper gage

pressure.

Add refrigerant if the Liquid Gage Pressure is lower than

the chart value.

1. Connect gages to refrigerant bottle and unit as

illustrated.

2. Purge all hoses.

3. Open bottle.

4. Stop adding refrigerant when liquid line temperature

and Liquid Gage Pressure matches the charging

chart Final Subcooling value.

Recover refrigerant if the Liquid Gage Pressure is higher

than the chart value.

20 MIN.

STEP 7 - Stabilize the system.

1. Wait 20 minutes for the system condition to

stabilize between adjustments.

Note: When the Liquid Line Temperature and Gage

Pressure approximately match the chart, the system is

properly charged.

2. Remove gages.

3. Replace service port caps to prevent leaks.

Tighten finger tight plus an additional 1/6 turn.

STEP 9 - Record System Information for reference.

Record system pressures and temperatures after

charging is complete.

Outdoor model number = _________________

Measured Outdoor Ambient = __________ º F

Measured Indoor Ambient = __________ º F

Measured Liquid Line Temp = __________ º F

Measured Suction Line Temp = __________ º F

Liquid Gage Pressure = __________ PSI

Suction Gage Pressure = __________ PSI

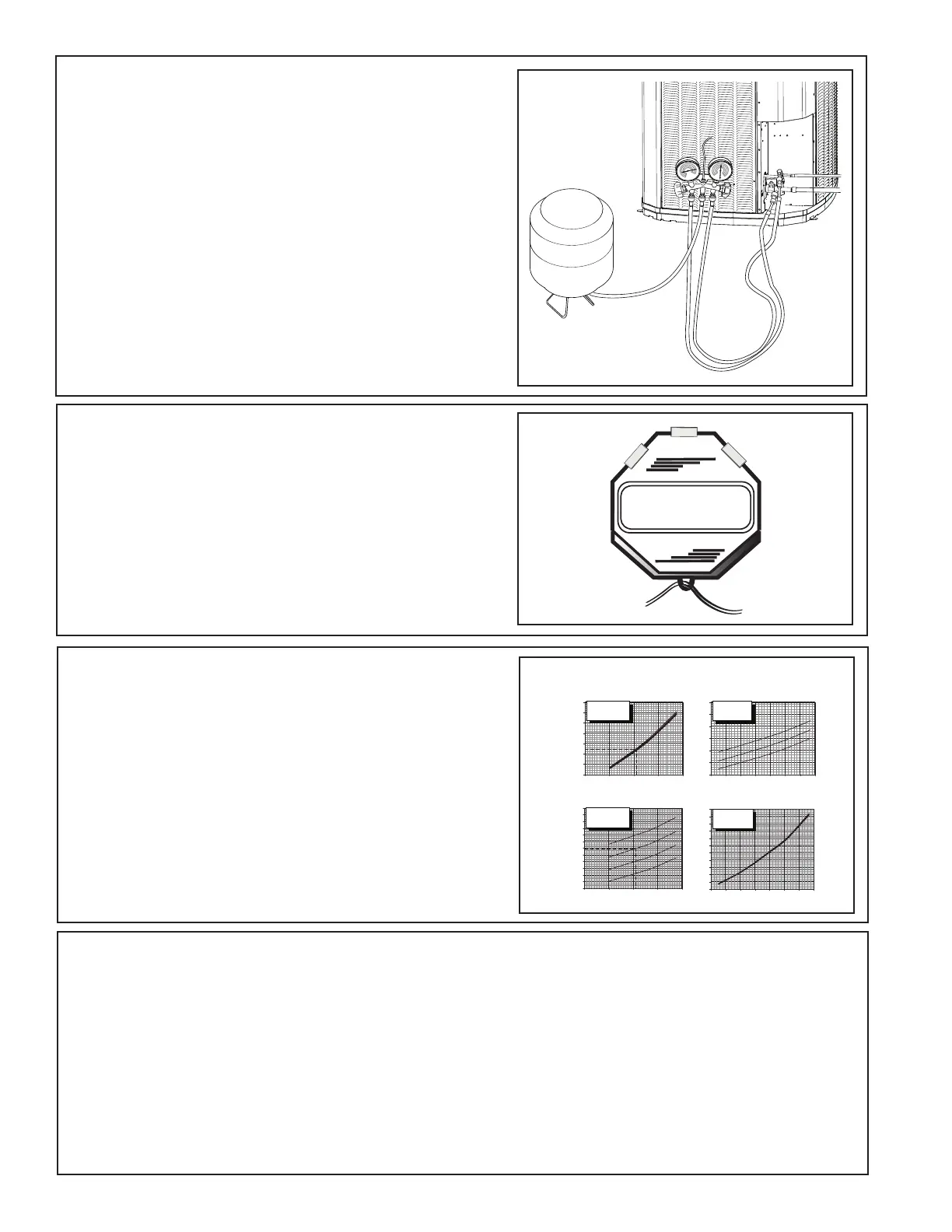

STEP 8 - Verify typical performance.

Refer to System Pressure Curves at the end of

the document to verify typical performance.

Cooling @ 1450 SCFM Heating @ 1350 SCFM

DISCHARGE PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

110

115

120

125

130

135

140

145

150

155

160

165

170

40 60 80 100 120

200

250

300

350

400

450

500

550

40 60 80 100 120

(1)

(1)

(3)

(3)

(5)

(4)

(2)

(2)

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM

71, 67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM

71, 67, 63 AND 59 DEG F.

30

40

50

60

70

80

90

100

110

120

130

140

-5 5152535455

5

200

250

300

350

400

450

500

-5 5152535455

5

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM

80, 70, AND 60 DEG F.

INDOOR ENTERING

DRY BULB CURVES

TOP TO BOTTOM

80, 70, AND 60 DEG F.

Loading...

Loading...