18-AC95D1-1 21

STEP 8 - Verify typical performance.

Refer to System Pressure Curves in the Service

Facts to verify typical performance.

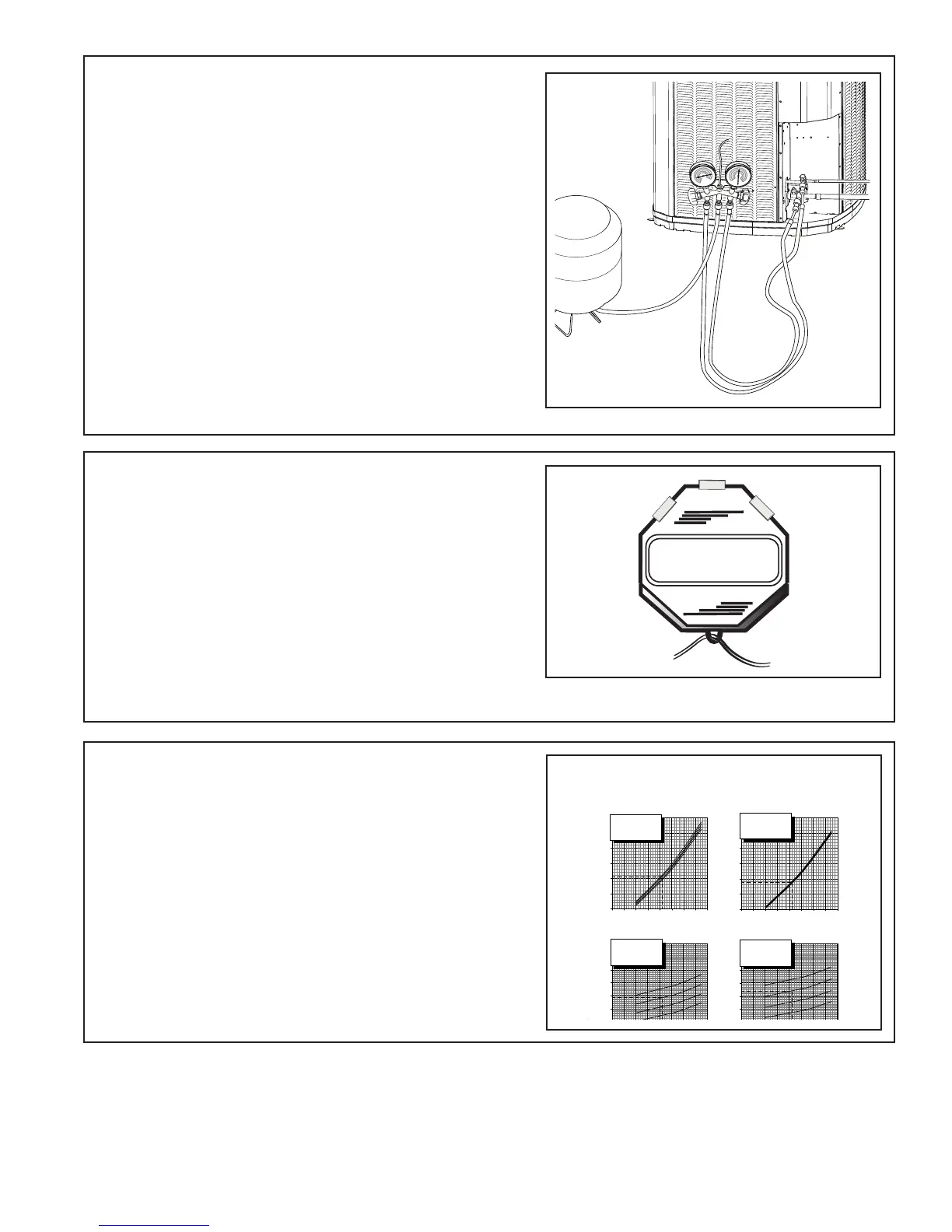

STEP 6 - Adjust refrigerant level to attain

proper gage pressure.

Add refrigerant if the Liquid Gage Pressure

is lower than the chart value.

1. Connect gages to refrigerant bottle

and unit as illustrated.

2. Purge all hoses.

3. Open bottle.

4. Stop adding refrigerant when liquid

line temperature and Liquid Gage

Pressure matches the charging chart

Final Subcooling value.

Recover refrigerant if the Liquid Gage Pres-

sure is higher than the chart value.

20 MIN.

STEP 7 - Stabilize the system.

1. Wait 20 minutes for the system condi-

tion to stabilize between adjustments.

Note: When the Liquid Line Temperature and

Gage Pressure approximately match the chart,

the system is properly charged.

2. Remove gages.

3. Replace service port caps to prevent

leaks. Tighten finger tight plus an ad-

ditional 1/6 turn.

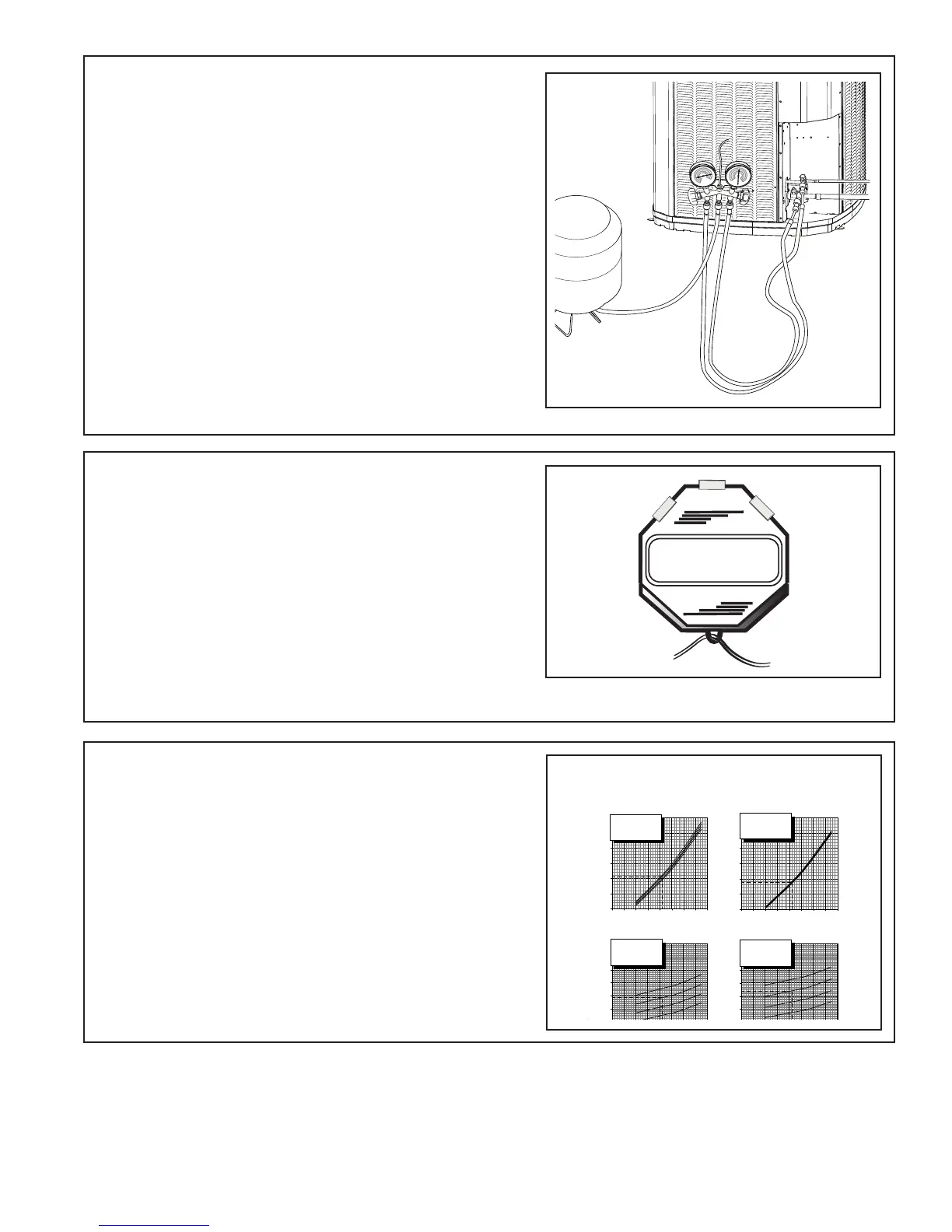

(Example only - see Service Facts)

PRESSURE CURVES FOR 4TTX6060E

EGATS DNOCESEGATS TSRIF

1A66F3EET41A66F3EET4

Cooling with Thermal Expansion Valve Cooling with Thermal Expansion Valve

LIQUID PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

ION PRESSURE (PSIG)

OUTDOOR TEMPERATURE (Degree F)

COOLING PERFORMANCE CAN BE CHECKED WHEN THE OUTDOOR TEMP IS ABOVE 65 DEG F.

TO CHECK COOLING PERFORMANCE, SELECT THE PROPER INDOOR CFM, ALLOW PRESSURES TO STABILIZE. MEASURE INDOOR WET BULB

TEMPERATURE, OUTDOOR TEMPERATURE, LIQUID AND SUCTION PRESSURES. ON THE PLOTS LOCATE OUTDOOR TEMPERATURE (1);

LOCATE INDOOR WET BULB (2); FIND INTERSECTION OF OD TEMP. & ID W.B. (3); READ LIQUID (4) OR SUCTION (5) PRESSURE IN LEFT COLUMN .

EGATS DNOCES :ELPMAXEEGATS TSRIF :ELPMAXE

.F 28 .PMET ROODTUO )1( .F 28 .PMET ROODTUO )1(

.F 76 BLUB TEW ROODNI )2( .F 76 BLUB TEW ROODNI )2(

NOITCESRETNI TA )3( NOITCESRETNI TA )3(

(4) LIQUID PRESSURE @ 1210 CFM IS 306 PSIG (4) LIQUID PRESSURE @ 1570 CFM IS 288 PSIG

(5) SUCTION PRESSURE @ 1210 CFM IS 139 PSI

(5) SUCTION PRESSURE @ 1570 CFM IS 144 PSI

INTERCONNECTING LINES ACTUAL:

GAS - 1 1/8" O.D. LIQUID PRESSURE SHOULD BE +/- 10 PSI OF CHART

LIQUID - 3/8" O.D. SUCTION PRESSURE SHOULD BE +/- 3 PSIG OF CHART

DWG.NO. 4TTX6060E1

110

120

130

140

150

160

170

180

40 50 60 70 80 90 100 110 120

110

120

130

140

150

160

170

180

40 50 60 70 80 90 100 110 120

200

250

300

350

400

450

500

40 50 60 70 80 90 100 110 120

200

250

300

350

400

450

500

40 50 60 70 80 90 100 110 120

(1)

(3)

(3)

(5)

(4)

(2)

(2)

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

INDOOR ENTERING

WET BULB CURVES

TOP TO BOTTOM 71,

67, 63 AND 59 DEG F.

(2)

(1)

(4) (3)

(2)

(3)

(5)

Loading...

Loading...