A801X-SVX001-1B-EN

23

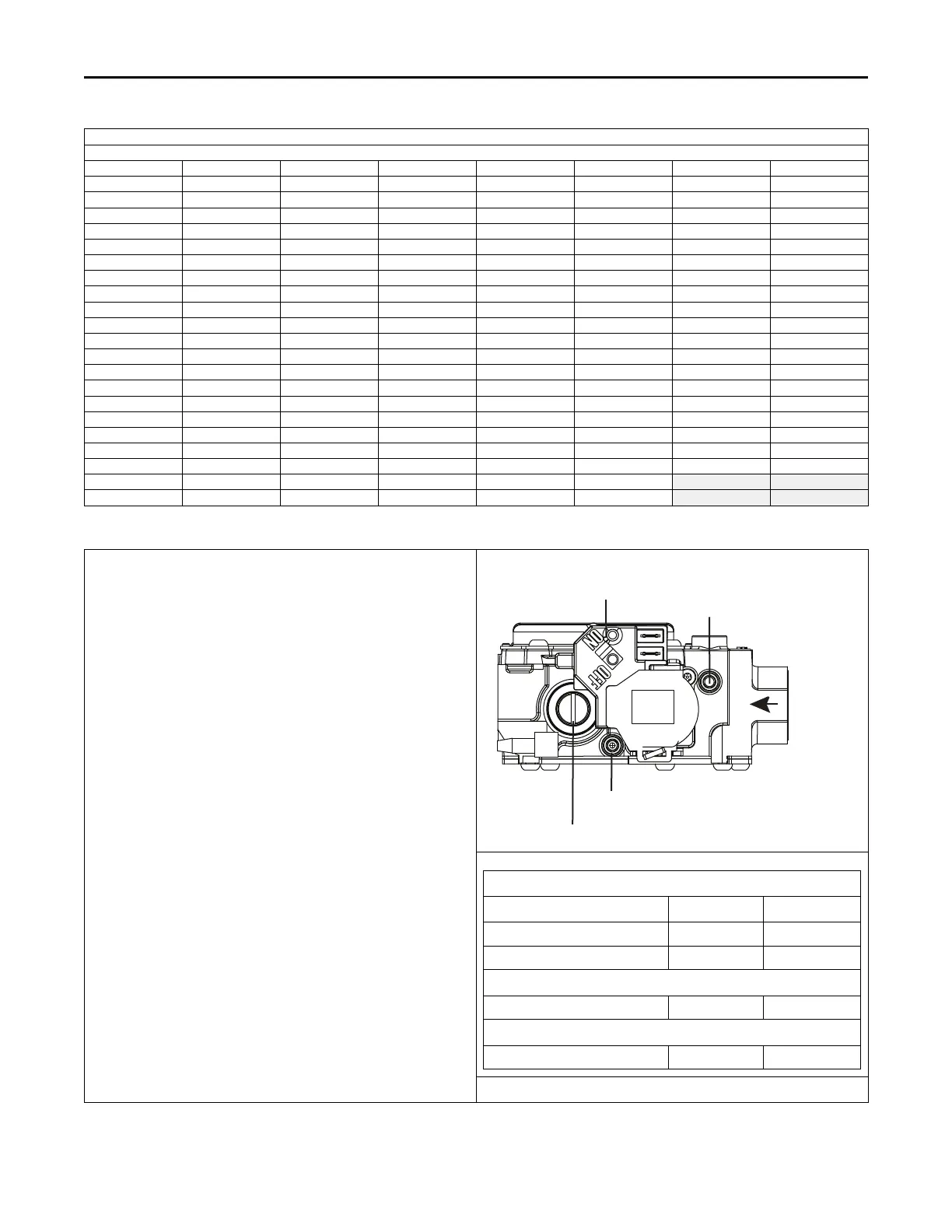

Gas Flow in Cubic Feet Per Hour

2 Cubic Foot Dial

Sec. Flow Sec. Flow Sec. Flow Sec. Flow

10 732 31 236 52 141 86 85

11 666 32 229 53 138 88 83

12 610 33 222 54 136 90 81

13 563 34 215 55 133 94 78

14 523 35 209 56 131 98 75

15 488 36 203 57 128 100 73

16 458 37 198 58 126 104 70

17 431 38 193 59 124 108 68

18 407 39 188 60 122 112 65

19 385 40 183 62 118 116 63

20 366 41 179 64 114 120 61

21 349 42 174 66 111 130 56

22 333 43 170 68 108 140 52

23 318 44 166 70 105 150 49

24 305 45 163 72 102 160 46

25 293 46 159 74 99 170 43

26 282 47 156 76 96 180 41

27 271 48 153 78 94 190 39

28 262 49 149 80 92 200 37

29 253 50 146 82 89

30 244 51 144 84 87

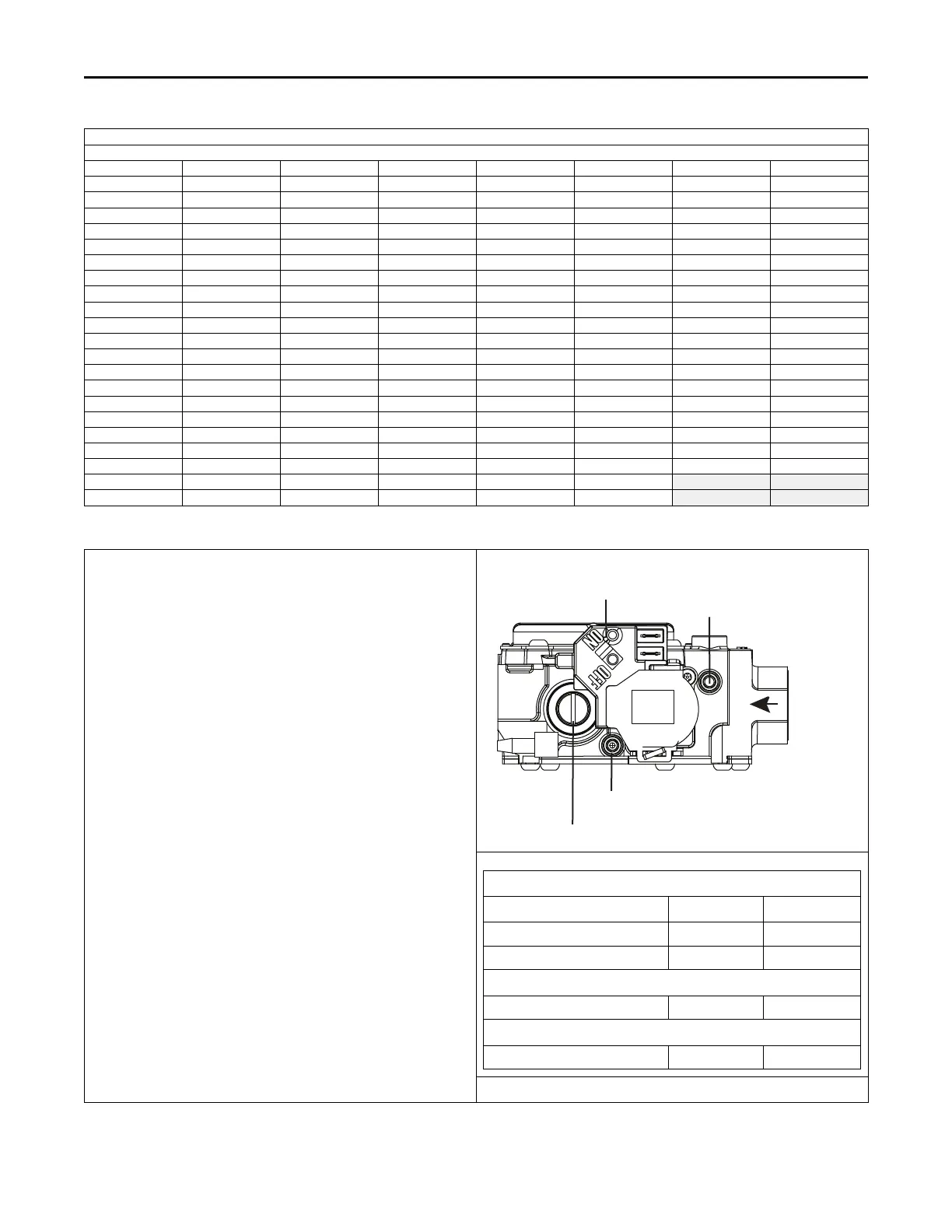

Gas Valve Adjustment

Changes can be made by adjusting the manifold pressure, or changing

orifices (orifice change may not always be required). To adjust the

manifold pressure:

1. Turn off all electrical power to the system.

2. Loosen (Do Not remove) the pressure tap test set screw one turn

with 3/32" hex wrench.

a. The pressure tap adjustment kit (KIT07611) contains a 3/32"

hex wrench, a 5/16" hose and a connector and can be

ordered through Global Parts.

3. Attach a manifold pressure gauge with flexible tubing to the outlet

pressure boss marked "OUT P" on White- Rodgers gas valve

model 36J.

4. Turn on system power and make a call for heating.

5. Adjust gas heat by removing the low (LO) adjustment regulator

cover screw.

a. To increase outlet pressure, turn the regulator adjust screw

clockwise.

b. To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c. Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d. Replace and tighten the regulator cover screw securely.

6. Cycle the valve several times to verify regulator setting.

a. Repeat steps 5-6 if needed.

7. Turn off all electrical power to the system.

8. Remove the manometer and flexible tubing and tighten the

pressure tap screw.

9. Using a leak detection solution or soap suds, check for leaks at the

pressure outlet boss and pressure tap test screw.

10. Turn on system power and check operation of the unit.

Outlet Pressure Boss

1st Stage (LO) Manifold Pressure Adjustment

Inlet Pressure

Boss

Gas Valve On/Off

Toggle Switch

White-Rodgers 36J

Maximum and Minimum INLET Pressure (inches w.c.)

Natural Gas Propane

Maximum 13.8 13.8

Minimum 5 11

Fuel Manifold Pressure Settings (inches w.c.)

All models 3.5 10

Orifice sizes for Natural Gas and Propane

All models 45 56

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Loading...

Loading...