18-CD19D8-18 33

Installer’s Guide

Orifice

Twist Drill

Size If

Installed

At Sea

Level

ALTITUDE ABOVE SEA LEVEL

and Orifice Required At Other Elevations

2000 3000 4000 5000 6000 7000 8000 9000 10000

42

43

44

45

46

47

42

44

45

46

47

48

43

44

45

47

47

48

43

44

45

47

47

49

43

45

46

47

48

49

44

45

47

48

48

49

44

46

47

48

49

50

45

47

48

49

49

50

46

47

48

49

50

51

47

48

50

50

51

52

54

55

56

57

58

54

55

56

58

59

55

55

56

59

60

55

55

57

59

60

55

56

57

60

61

55

56

57

60

62

55

56

58

61

62

56

56

59

62

63

56

56

59

63

63

56

57

60

63

64

From National Fuel Gas Code - Table F-4

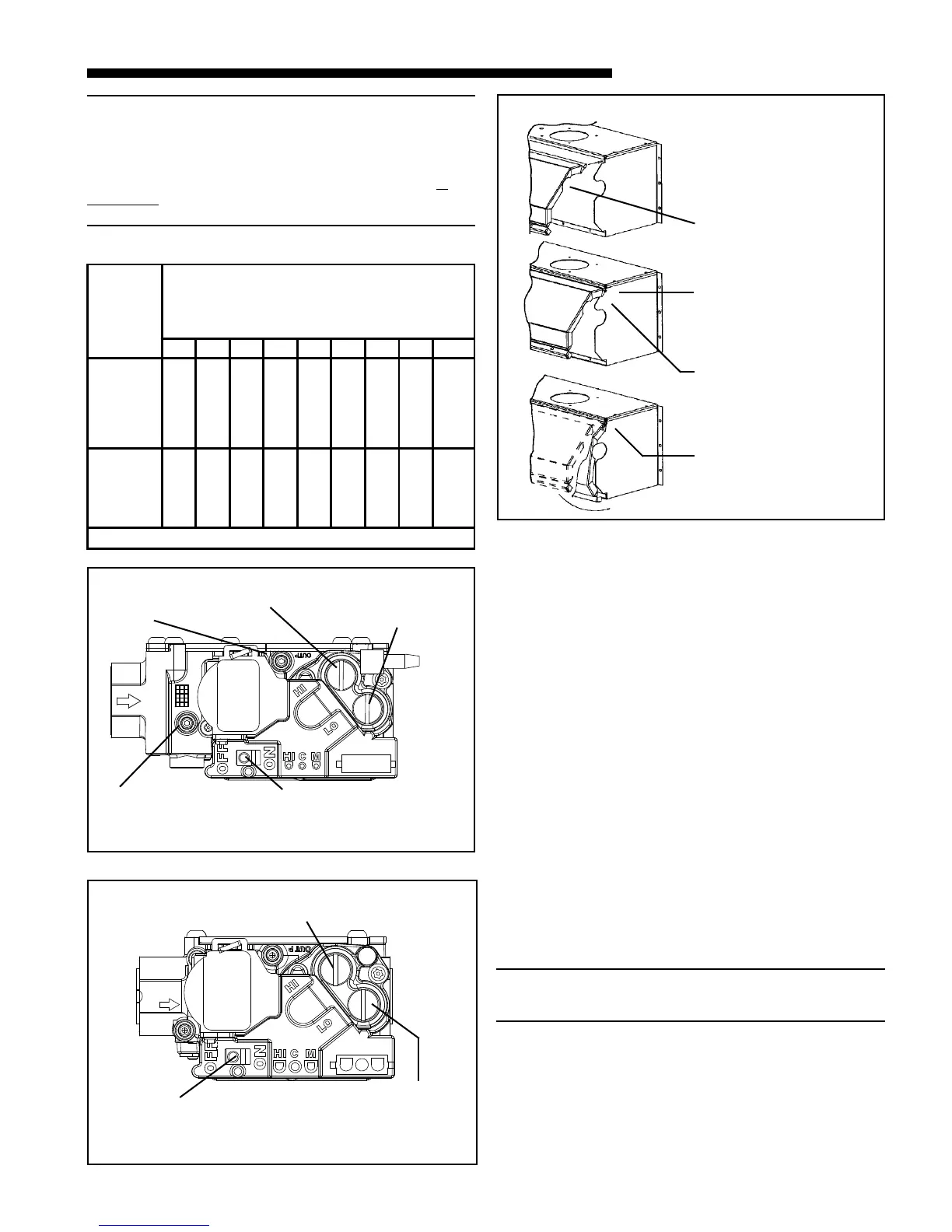

ROTATE THE FRONT

COVER INWARD MAKING

SURE THAT ALL SIDE

FLANGES ARE OUTSIDE

OF THE BOX.

INSERT THE TOP FLANGE

OF THE FRONT COVER

UNDER THE LIP INSIDE

THE BOX

ALL SIDE FLANGES MUST

BE OUTSIDE OF THE BOX

ROTATE THE FRONT

COVER AS SHOWN

T

HIGH ALTITUDE DERATE

Input ratings (BTUH) of these furnaces are based on sea

level operation and should not be changed at elevations up to

2,000 ft.

If the installation is 2,000 ft. or above, the furnace input rate

(BTUH) shall be reduced 4% for each 1,000 ft. above sea level.

The furnace input rate shall be checked by clocking the gas

flow rate (CFH) and multiplying by the heating value

obtained from the local utility supplier for the gas being

delivered at the installed altitude. Input rate changes can be

made by adjusting the manifold pressure (min 3.0 - max

3.7 in. W.C. - Natural Gas) or changing orifices (orifice change

may not always be required).

If the desired input rate cannot be achieved with a change in

manifold pressure, then the orifices must be changed. LP

installations will require an orifice change.

IMPORTANT:

Reinstall the propane orifices to the same depth as the orifices

supplied with the equipment.

Installation of this furnace at altitudes above 2,000 ft.

(610m) shall be in accordance with the local codes, or in the

absence of local codes, the National Fuel Gas Code, ANSI

Z223.1/ NFPA 54 or National Standard of Canada, Natural

Gas and Propane Installation Code, CSA 149.1. Installation of

this furnace at altitudes above 2,000 ft. (610m) shall be made

in accordance with the listed high Altitude Conversion Kit

available with this furnace.

TABLE 18

See Table 18 for help in selecting orifices if orifice change is

required. Furnace input rate and temperature rise should be

checked again after changing orifices to confirm the proper rate

for the altitude.

The vent length table on page 16 shows the required vent

lengths for installations at various altitudes. An optional

high altitude kit is available for installations above 5000 feet

Installations above 12,000 feet are not allowed).

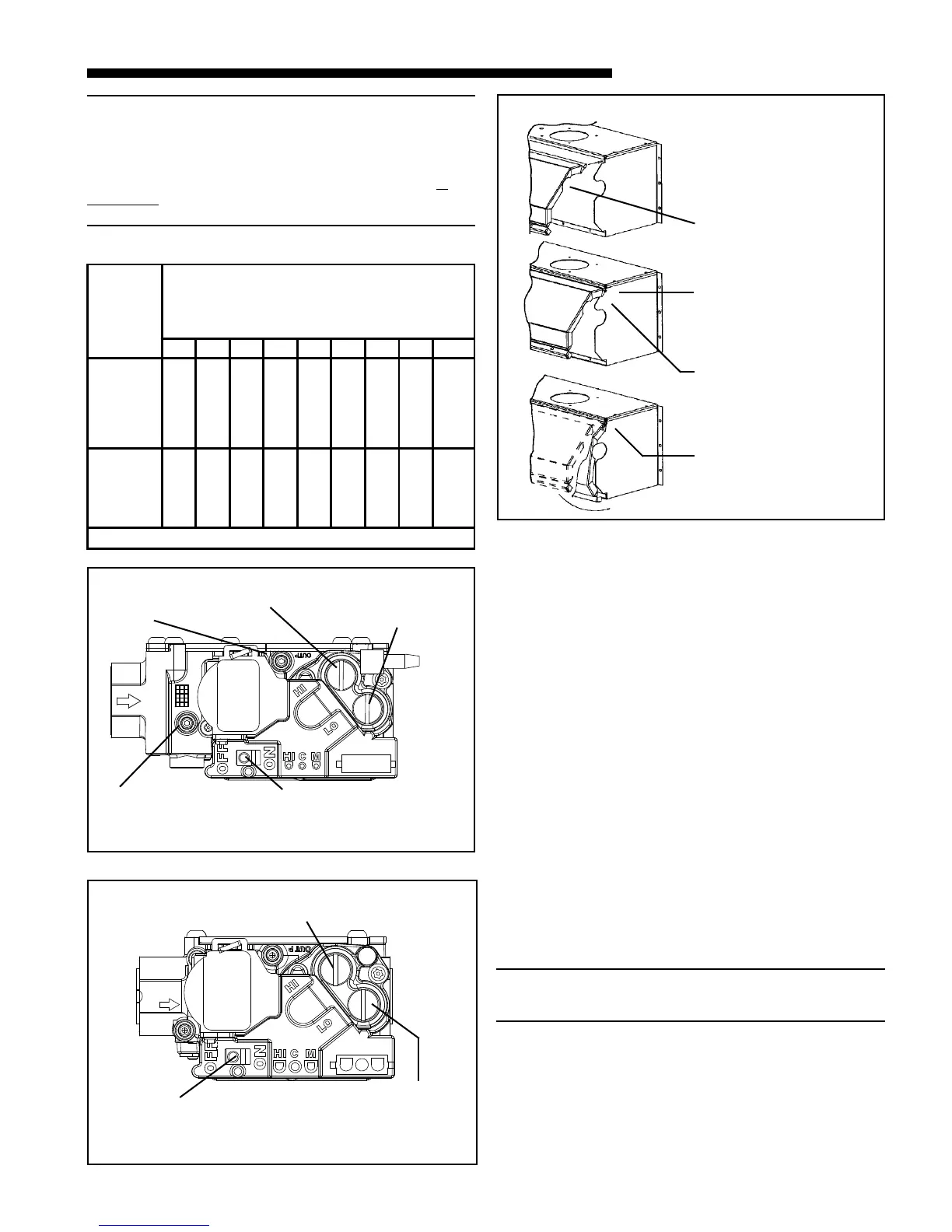

NOTE:

The manifold pressure must be referenced to the burner

box. The burner box pressure tap equalizes the gas valve

pressure regulator. Manifold pressure is checked by

installing a tee (field supplied) in the tubing, between the tee

coming from the burner box tube and the gas valve,

in

addition to

the regular gas valve pressure tap on the

outlet side of the gas valve. See Figure 52.

2nd Stage (HI) Manifold

Pressure Adjustment

Gas Valve On / Off

Toggle Switch

1st Stage (LO)

Manifold Pressure

Adjustment

Figure 53. White-Rodgers 36J

2nd Stage (HI) Manifold

Pressure Adjustment

Gas Valve On / Off

Toggle Switch

1st Stage (LO)

Manifold Pressure

Adjustment

Figure 54. White-Rodgers 36G

Outlet

Pressure

Boss

Inlet Pressure

Boss

Loading...

Loading...