SS-APG008-EN 1

Overview

Trane’s TTA and TWA 6- through 20-ton condensing unit product line (specific model numbers are

listed on the cover) has been designed for use only with R-410A and POE oil. R-410A is a higher

pressure refrigerant that requires the other components of the system to be rated for the higher

pressures. For compressor lubrication, the refrigerant requires POE oil.

Traditionally, refrigerant piping practices were guided by four principles:

• Return the oil to the compressor.

• Maintain a column of liquid at the expansion valve.

• Minimize the loss of capacity.

• Minimize the refrigerant charge in the system.

These piping practices are the same for R-410A and POE oil. However, because of the different mass

flows and pressures, the line diameter required to carry the oil and refrigerant may not be the same

as a similar tonnage R-22 unit. Also, the allowable pressure drop may be greater for R-410A than

R-22.

Evidence accumulated over years of observation demonstrates that the lower the refrigerant

charge, the more reliably a split air-conditioning system performs. Any amount of refrigerant in

excess of the minimum design charge becomes difficult to manage. The excess refrigerant tends

to collect in areas that can interfere with proper operation and eventually shortens the service life

of the system.

To successfully minimize the system refrigerant charge, the correct line size should be used and the

line length must be kept to a minimum.

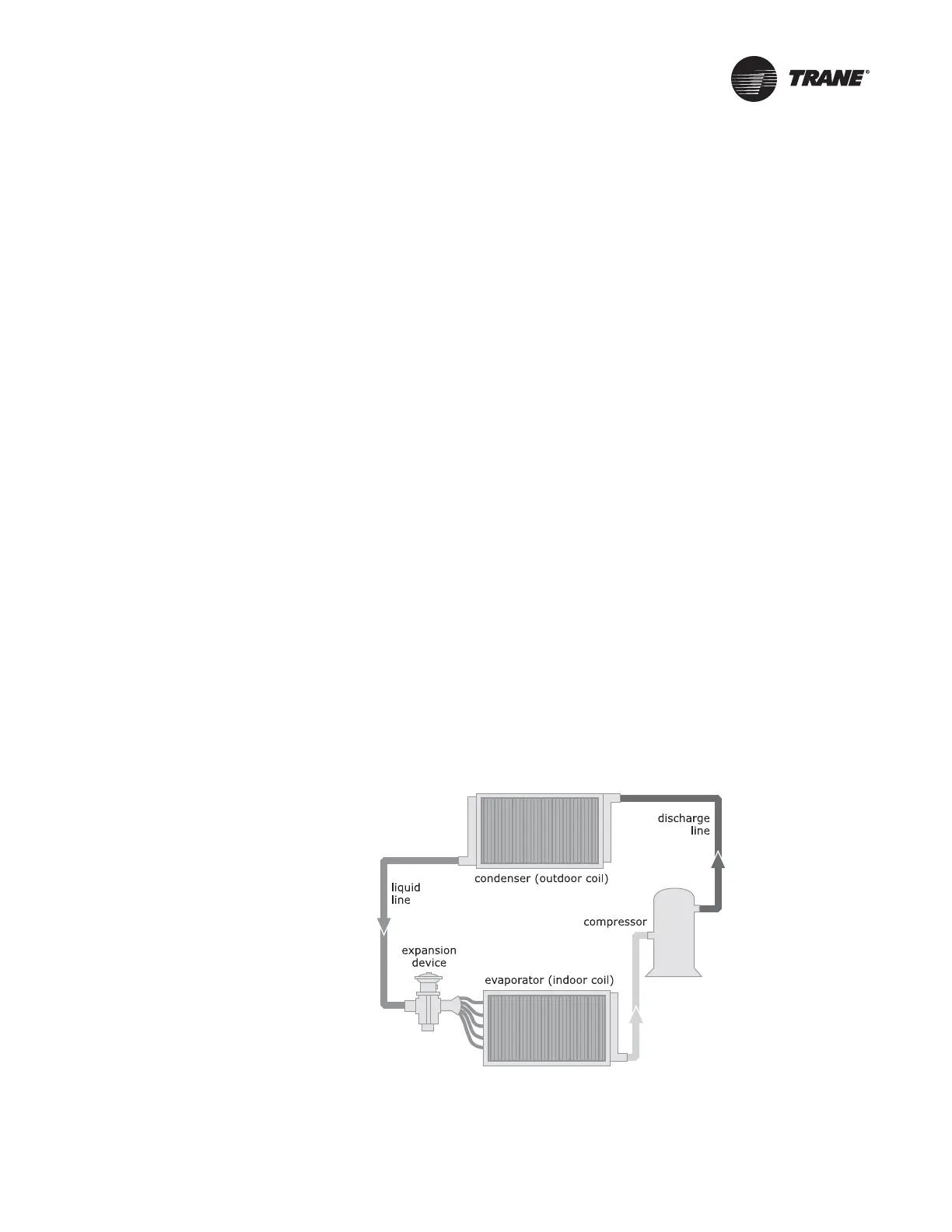

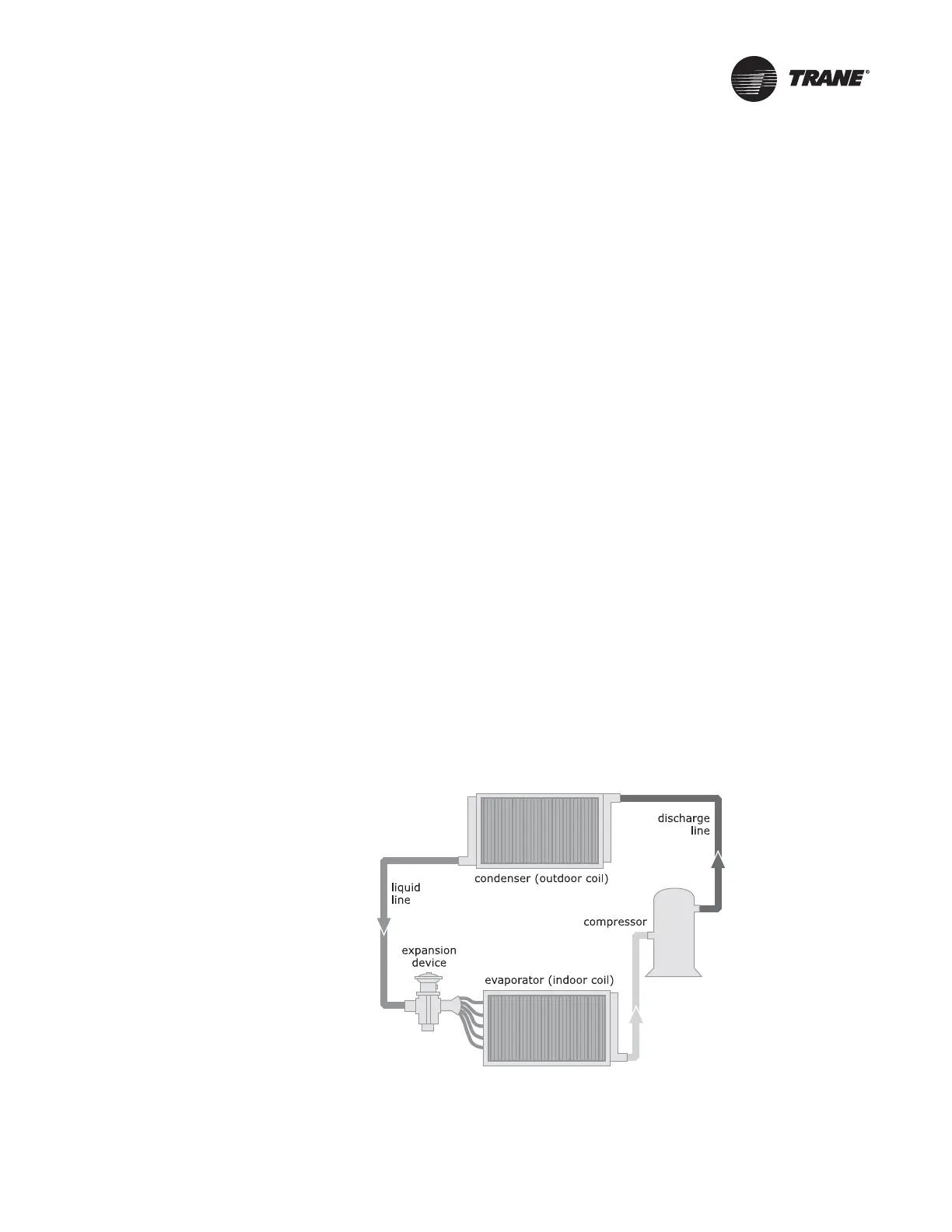

Background

In a split air-conditioning system, the four major components of the refrigeration system are

connected by field-assembled refrigerant piping (Figure 1). A vapor or gas line connects the

evaporator to the compressor, the discharge line connects the compressor to the condenser, and

the liquid line connects the condenser to the expansion device, which is located near the

evaporator inlet. Operational problems can occur if these refrigerant lines are designed or installed

improperly.

Figure 1. Interconnecting refrigerant lines in a typical split air-conditioning system

Loading...

Loading...