as well as during inspections, to make certain that the

Automatic Drain Valve is open.

When one or more automatic sprinklers operate in re-

sponse to a fire, air pressure within the system piping is

relieved. When the air pressure becomes sufficiently re-

duced, the water pressure overcomes the differential hold-

ing the Clapper Assembly closed and the Clapper Assem-

bly swings clear of the water seat to permit waterflow into

the system piping and subsequently to be discharged

from any open sprinklers.

Under full flow conditions, the Clapper Assembly will

open as shown in Figure 2-B. Also, with the Clapper As-

sembly open, the intermediate chamber is pressurized

and water flows through the alarm port at the rear of the

Model A-1 Dry Pipe Valve to actuate system waterflow

alarms. The flow from the alarm port is also sufficient to

close the otherwise normally open Automatic Drain Valve

(5 - Fig. 4).

As an option, the Model A-1 Dry Pipe Valve may be

equipped with a Model S430 Dry Pipe Valve Accelerator

to reduce the time for the Dry Pipe Valve to open follow-

ing the operation of one or more automatic sprinklers,

and in some cases may be required to meet the require-

ments of NFPA 13 for systems having a capacity greater

than 500 gallons (1890 litres). Refer to Figure 7 and Prod-

uct Data Sheet 2-5.4.10.

DESIGN CRITERIA

The Model A-1 Dry Pipe Valve must be installed vertically

as shown in Figure 6, and it must be installed in a readily

visible and accessible location, where the valve and asso-

ciated trim must be maintained at a minimum tempera-

ture of 40°F/4°C.

NOTE

Heat tracing of the Model A-1 Valve or its associated trim

is not permitted. Heat tracing can result in the formation

of hardened mineral deposits which are capable of pre-

venting proper operation.

In planning the installation, consideration must also be

given to the disposal of the large quantities of water

which may be associated with draining the system, per-

forming a flow test, or performing a system trip test.

Installation configuration and clearance dimensions are

given in Figure 6. The flanged inlet connection is faced

and drilled per ANSI Standard B16.1, unless otherwise

specified when ordered.

Review the requirements of NFPA 13 with respect to the

requirements for quick opening devices (Model S430 Dry

Pipe Valve Accelerator), air compressor sizing, waterflow

alarms, and low pressure alarm switches.

STAR SPRINKLER INC.

Page 2

2-2.1.31

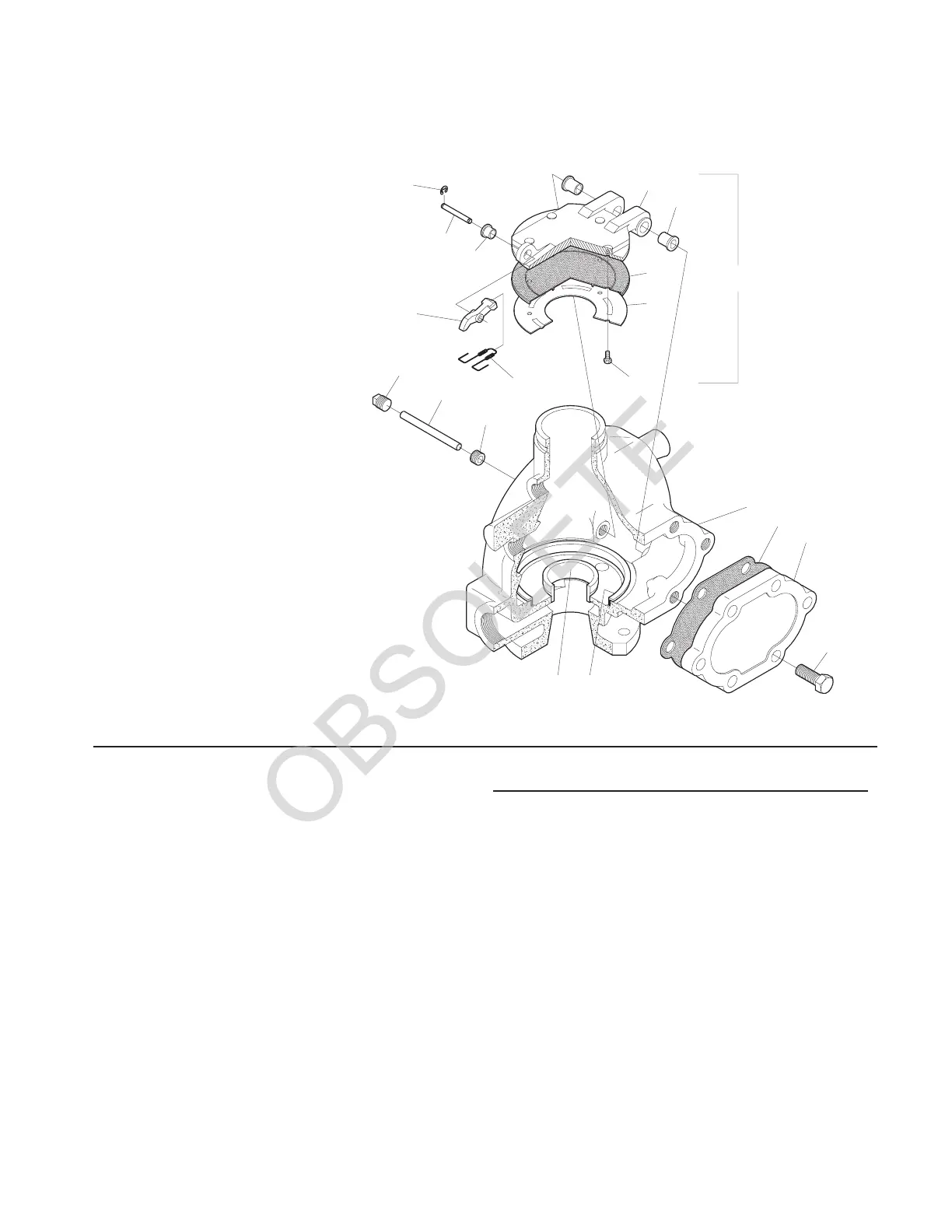

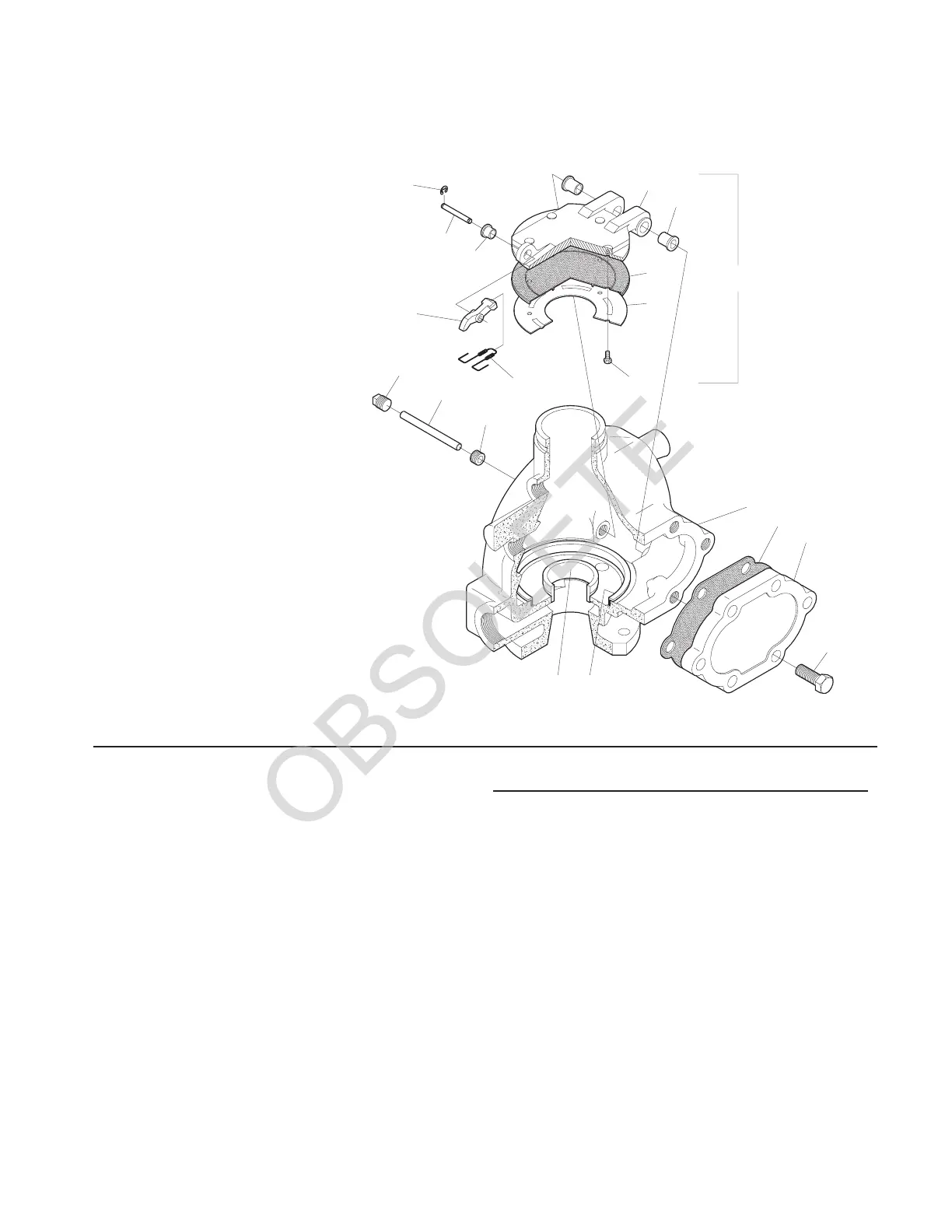

FIGURE 1

4 INCH (DN100) MODEL A-1

DRYPIPEVALVE

ASSEMBLY

1

5

4

CLAPPER

ASSEMBLY

9

8

7

19

18

16

17

11

10

12

13

15

14

32

6

NO. DESCRIPTION....QTY. PART

1 Body .......... 1 NR

2 WaterSeatRing.... 1 NR

3 AirSeatRing...... 1 NR

4 Handhole Cover .... 1 400-02-000

5 Handhole Cover Gasket 1 400-04-000

6 Handhole Cover Bolt,

3/4-10UNCx2" .... 6 600-03-000

7 Clapper ......... 1 400-182-00

8 Clapper Facing ..... 1 400-191-00

9 Clapper Facing

Retainer ........ 1 400-190-00

10 Clapper Facing

RetainerBolts ..... 5 600-80-000

11 Clapper Latch ..... 1 300-10-000

12 Clapper Latch Spring . 1 300-21-000

13 Clapper Latch

HingePin........ 1 300-23-000

14 Clapper Latch

Hinge Pin

RetainingRing..... 2 300-22-000

15 Clapper Latch

Hinge Pin Bushing . . . 2 818-08-000

16 Clapper Hinge Pin . . . 1 8010-10-20

17 Body

Bushing......... 2 600-187-01

18 Clapper Hinge Pin

Plug,1/2"NPT..... 2 8010-12-00

19 Clapper Hinge Pin

Clapper Bushing .... 2 8010-08-00

— Clapper Assembly . . . 1 400-186-00

NR — Not Replaceable

Loading...

Loading...