18 Installation and maintenance instructions ecoTEC plus 0020238195_07

7 Installation

7.1 Preparing for installation

▶ Make sure that the existing gas meter and the pipelines

are capable of passing the rate of gas supply required.

▶ Consider the maximum heat output given in DHW mode.

▶ Install the following components:

– Draining cocks at the lowest points in the heating

installation (→ current version of "BS 2879")

– A bypass that is at least 1.5 m away from the product

– A stopcock in the gas pipe

– Where applicable, a flow regulator valve to adjust the

flow rate

▶ Install the connection pipes such that they are free from

mechanical stress.

▶ If you use non-diffusion-tight plastic pipes in the heating

installation, ensure that no air gets into the heat gener-

ator circuit.

▶ Only solder connectors if the connectors are not yet

screwed to the service valves.

▶ Only bend connection pipes if they have not yet been

connected to the product.

▶

Flush the heating installation thoroughly before installing

the product.

▶ Check the leak-tightness of the gas valve assembly using

a pressure of ≤ 11 kPa (110 mbar).

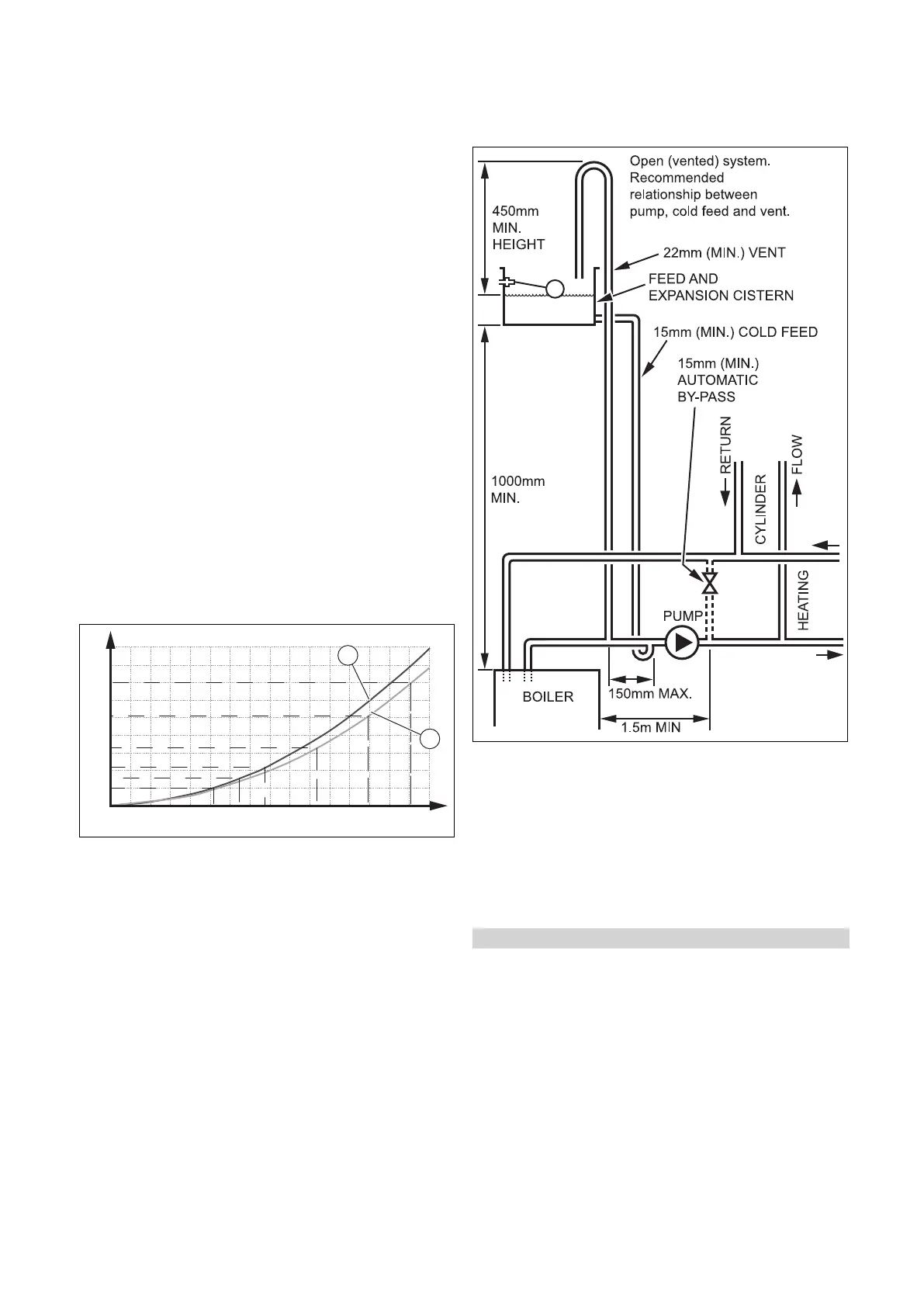

7.2 Installing the heating pump

Pressure loss in the product

from the product

0

50

100

150

200

250

300

350

400

0 200 400 600 800 1000 1200 1400 1600

430

424

418

415

412

435

A

B

1

2

A Flow rate [l/h]

B Pressure loss [mbar]

1 Pressure loss 412 - 418

2 Pressure loss 424 - 435

The flow rate must not fall below the value in the diagram.

▶ Only use pumps that have an in-rush current ≤ 10/15 A.

▶ When designing/selecting the pump, note the pressure

loss of the product.

▶ Install the pump in the heating flow.

▶ Install the pump upstream and downstream of the pump

isolation valves.

▶ Set the pump so that the temperature difference between

the flow and return is no more than 20 °C when the max-

imum flow temperature is set.

– The flow rate specified in the technical data is

reached.

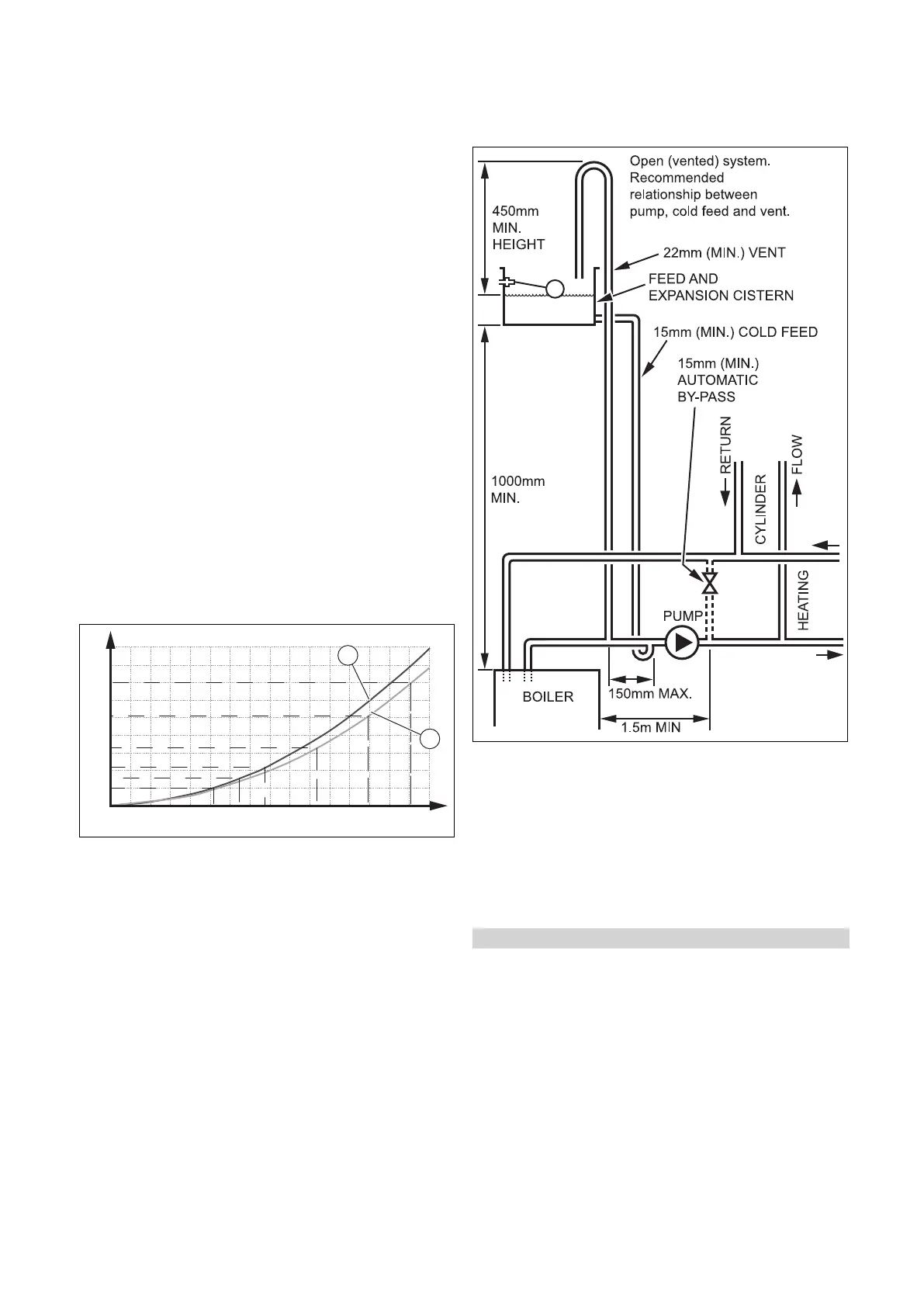

7.3 Heating water supply in the open heating

system

▶ Connect the product to a supply/expansion tank as

shown in the figure.

– The tank must not be more than 27 m (90 ft) above

the product.

– The open vent pipe must be installed with an upward

gradient and must not be blocked.

– Supply pipe diameter: ≥ 15 mm

– The relative positions of the pump, supply and open

vent pipe must be as shown in the figure.

Condition: Combined supply and open vent pipe

▶ Install the line in accordance with "BS 5449".

– Diameter: ≥ 22 mm

Loading...

Loading...