PS (3-Phase) Series Maintenance

wc_tx000124gb.fm 23

5. Maintenance

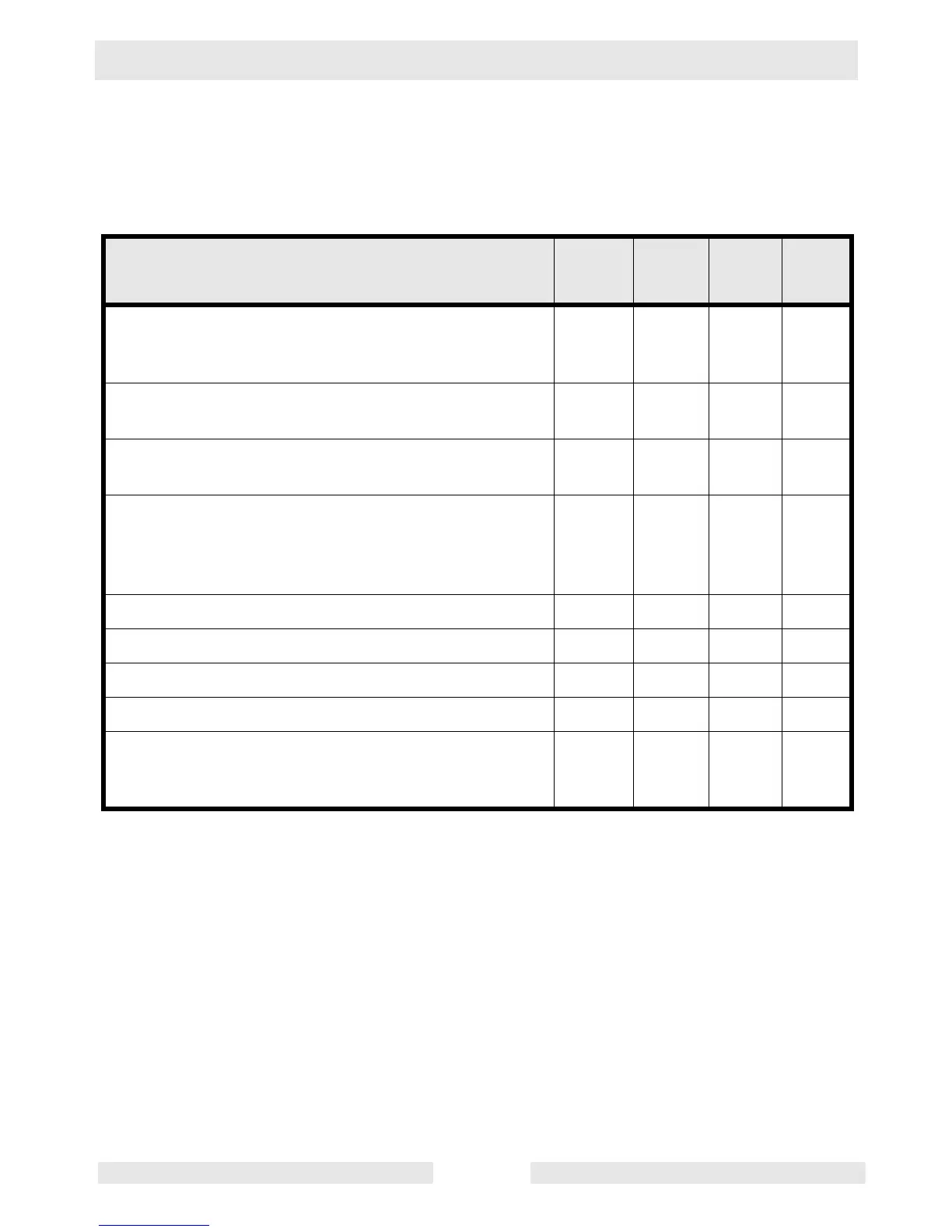

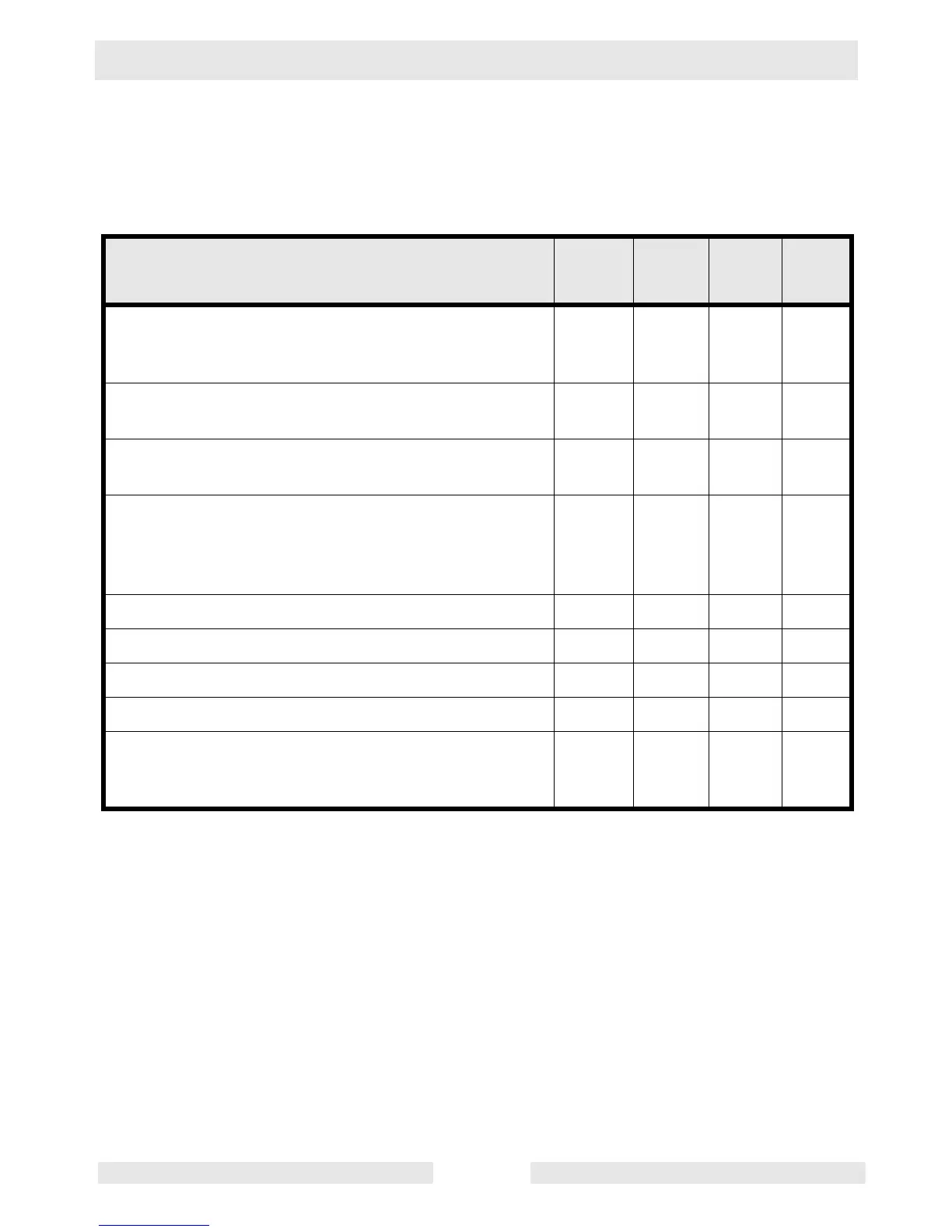

5.1 Periodic Maintenance Schedule

Pump

Monthly Every

3000

hrs.

Every

6000

hrs.

Every

2–5

years

Measure insulation resistance.

Reference insulation resistance =

1MW or greater. (1)

•

Measure operating current.

Compare with rated current.

•

Measure supply voltage. Compare with allowable

range (within ±5% of rated voltage).

•

Pump inspection. A noticeable drop in performance

may indicate wear in the impeller, etc., or else clog-

ging of the strainer, etc. Remove the clogged debris

and replace any worn parts.

•

Lubricant inspection. •

Change lubricant. •

Designated lubricant: SAE 10W/20W. (2)

Change mechanical seal. (3) •

Overhaul. This should be carried out even if there

are no problems with the pump. The frequency

depends on how continuously the pump is in use. (4)

•

(1)

If the insulation resistance has become noticeably lower than the previous

inspection, an inspection of the motor will be necessary.

(2)

See Lubricant Inspection and Change in this section.

(3)

Specialized knowledge is required for inspecting and replacing the mechanical

seal. Consult with your nearest dealer or Wacker representative.

(4)

Consult with your nearest dealer or Wacker representative regarding overhauls.

Loading...

Loading...