TYPICAL FLOW RATES AS SIZED BY FLOOR DRAIN MANUFACTURERS

2" 55 GPM 5" 350 GPM

3" 112 GPM 6" 450 GPM

4" 170 GPM 8" 760 GPM

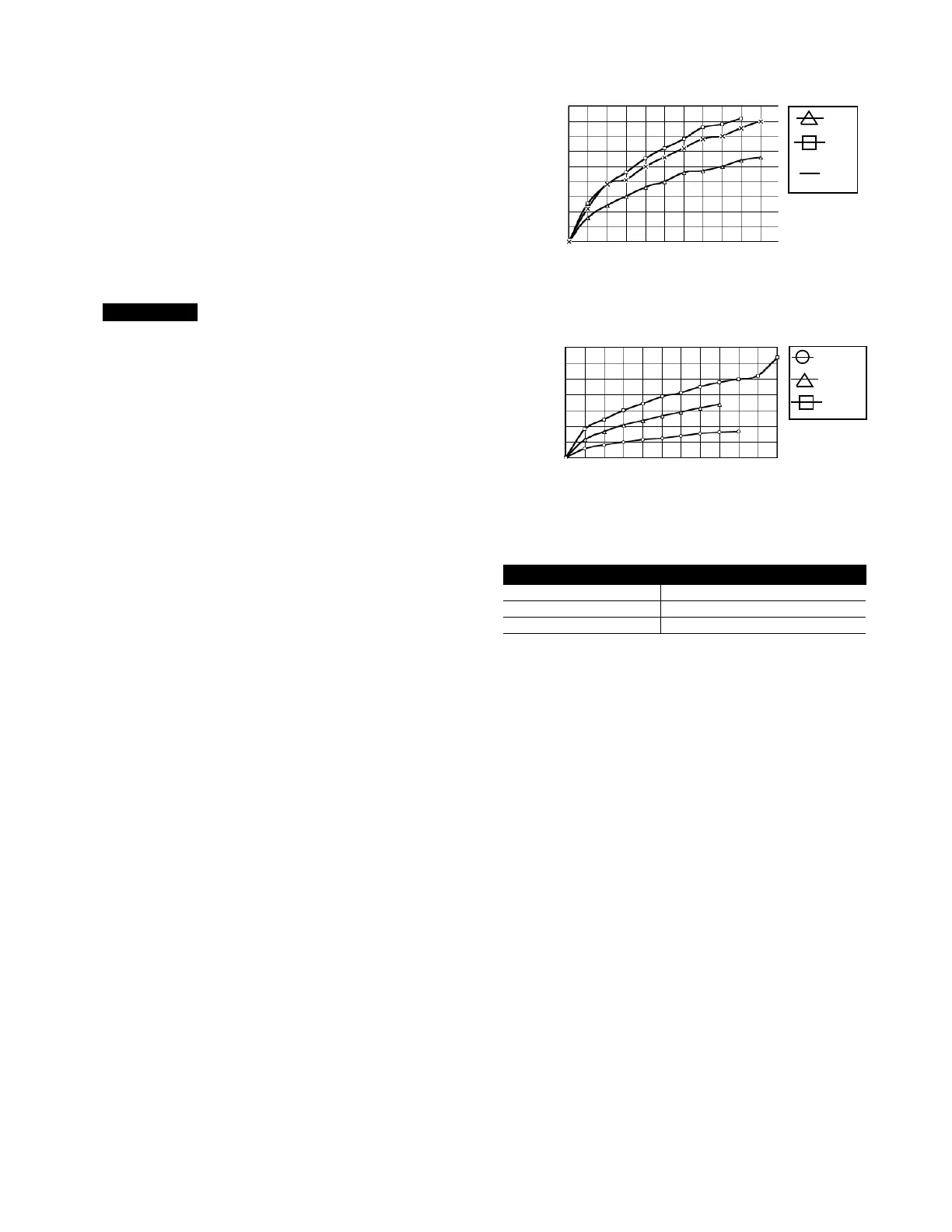

Figure 4

Relief Valve Discharge Rates

1

⁄2" – 1"

45

40

35

30

25

20

15

10

5

0

0 10 20 30 40 50 60 70 80 90 100 150

Zone Pressure psi

Flow Rate gpm

1

⁄2"

3

⁄4" M2

1" M2

X

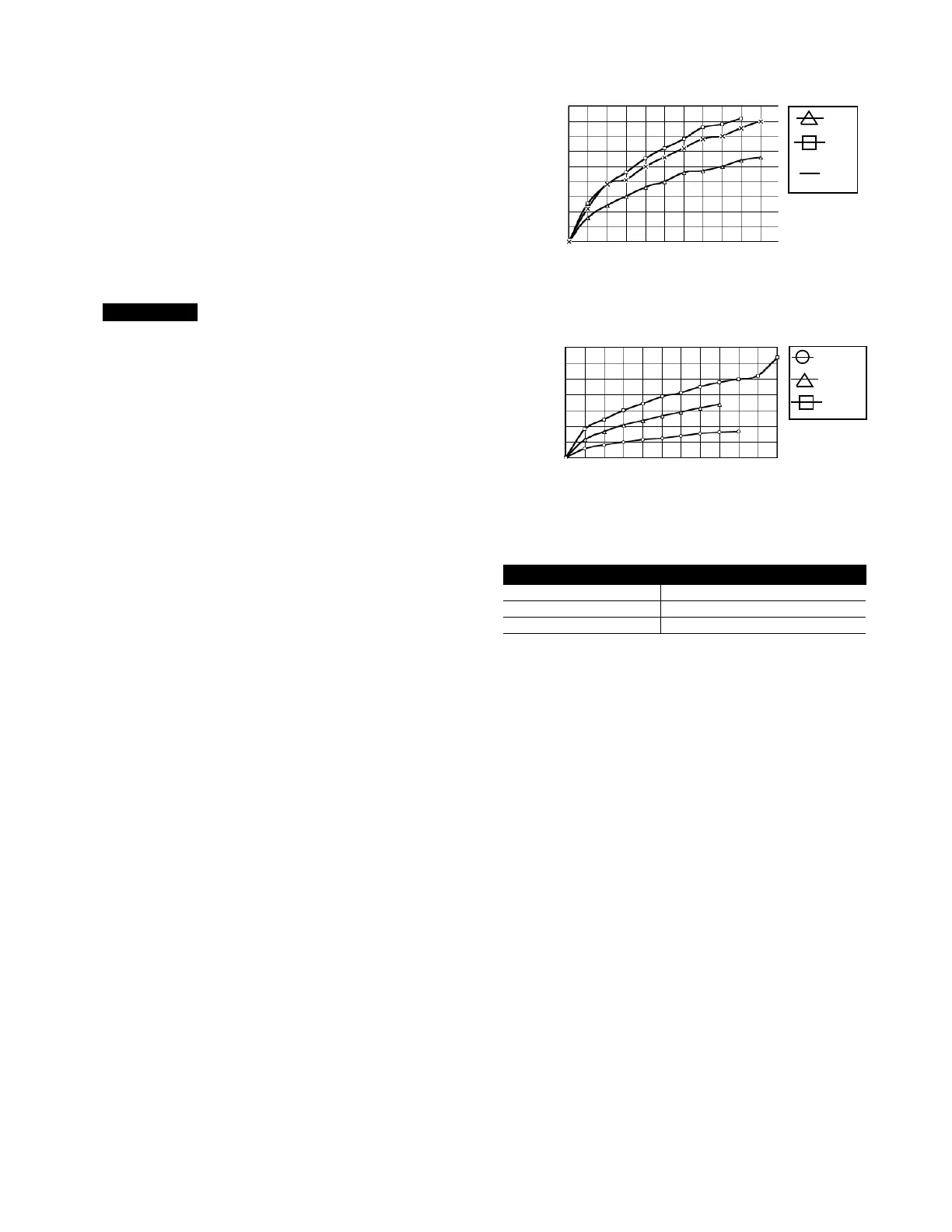

1

1

⁄4" – 3"

350

300

250

200

150

100

50

0

0 10 20 30 40 50 60 70 80 90 100 150

Zone Pressure psi

Flow Rate gpm

2

1

⁄2" – 3"

2" M2

1

1

⁄4" – 1

1

⁄2" M2

3

NOTICE

Special considerations are necessary when testing as sem-

blies installed on Fire Prevention Systems.

Fire Protection System Installations: The National Fire

Protection Agency (NFPA) Guidelines require a confirming flow

test be con duct ed whenever a “main line

” valve such as a back-

flow assembly or the shutoff valves have been operated. Certified

testers of backflow assemblies must conduct this confirming test.

F. The backflow preventers must be inspected periodically for any

discharge from the relief valve which provides a visual indication

of need for cleaning or repair of check valves. Also testing for

proper operation of the device should be made periodically in

compliance with local codes, but at least once a year or more

often, depending upon system

conditions.

The relief vent discharges water when, during no-flow periods,

the first check valve is fouled or the inlet pressure to the device

drops sufficiently due to upstream pressure fluctuations to affect

the required operating differential between the inlet pressure and

reduced pressure zone. Otherwise, such relief (spitting) can

occur when the second check is fouled during emergency back-

flow or resulting from a water hammer condition. (For more

information, download Troubleshooting Guide S-TSG at

watts.com.)

Loading...

Loading...