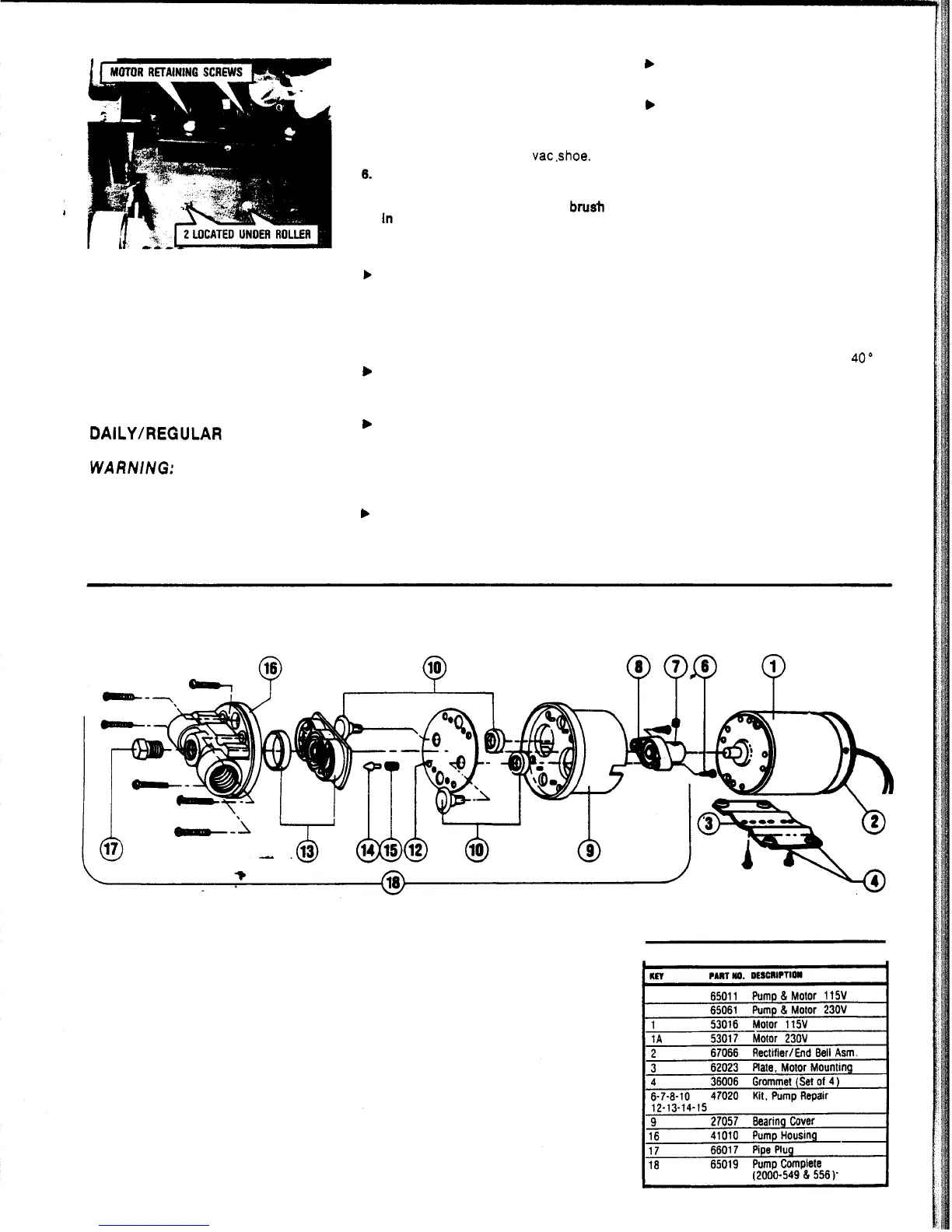

5.

Return machine to upright position

and lift

out

motor. Repair or replace

as required.

NOTE:

When reinstalling motor, make

sure motor pulley is in line with brush

pulley. Use straight edge for align

-

ment

if

needed. After assembly run

machine on carpet

to

check for belt

slippage

-

move motor rearward

to

tighten belt.

DAILYIREGULAR

MAINTENANCE

WARNING:

Before making any ad

-

justments or repairs, unplug machine

from electrical source.

1.

Empty unused cleaning solution

using clear plastic hose located on

lower back of solution tank.

2.

Inspect and clean filter screen in

solution tank.

3.

Flush pumping system with

1

to

3

gallons of clean, hot water.

4.

Rinse recovery tank with clean water.

5.

Check for and remove any lint or

debris around brush and

vac.shoe.

8.

Check spray jets and clean solenoid

valve

if

required.

NOTE:

Always

store

ADM with

bruall

In

“store”

position.

PERIODIC MAINTENANCE

b

Twice a month, flush a white vinegar

solution (one quart vinegar to two

gallons of water) or anti

-

browning

solution (mixed as directed) through

the extractor. This will prevent build

up of alkaline residue in the system.

b

Check sliding handle lock for exces

-

sive looseness, and hand tighten knob

on left side of handle as required.

b

If spray jets become clogged, remove

the spray tips, wash them thoroughly,

and blow dry.

NOTE:

Do

not use pins, wire, etc. to

clean nozzles as this could destroy

spray pattern.

b

If spray jets drip after the pump is

turned off, sclenoid valve may need

to be cleaned.

b

Apply silicone lubricant

to

solution

nipple.

b

Periodically inspect all hoses, elec

-

trical cables, filters and connections

on your machine. Frayed or cracked

hoses should be repaired or replaced

to eliminate vacuum or solution pres

-

sure

loss.

Because the electrical

cable will lie on wet carpet at times,

the cable must be well insulated and

cable connector screws kept tight.

If

the cable insulation is broken or

frayed, repair or replace it immedi

-

ately. Don’t take chances with an

electrical fire or shock.

PROTECT

FROM

FREEZING

If it becomes necessary

to

store in tem

-

peratures that could drop below

40”

F,

the pumping system, hoses and valves

must be protected from freezing with a

methyl hydrate window washer anti

-

freeze solution.

Do

not

use ethylene

glycol or cooling system antifreezes.

1.

Add a gallon or two of window washer

antifreeze to the supply tank, turn on

pump switch and spray until the anti

-

freeze solution fills the solution lines.

2.

Drain out the leftover antifreeze from

the supply tank. Always allow the unit

to

reach room temperatures before

filling with hot water or operating.

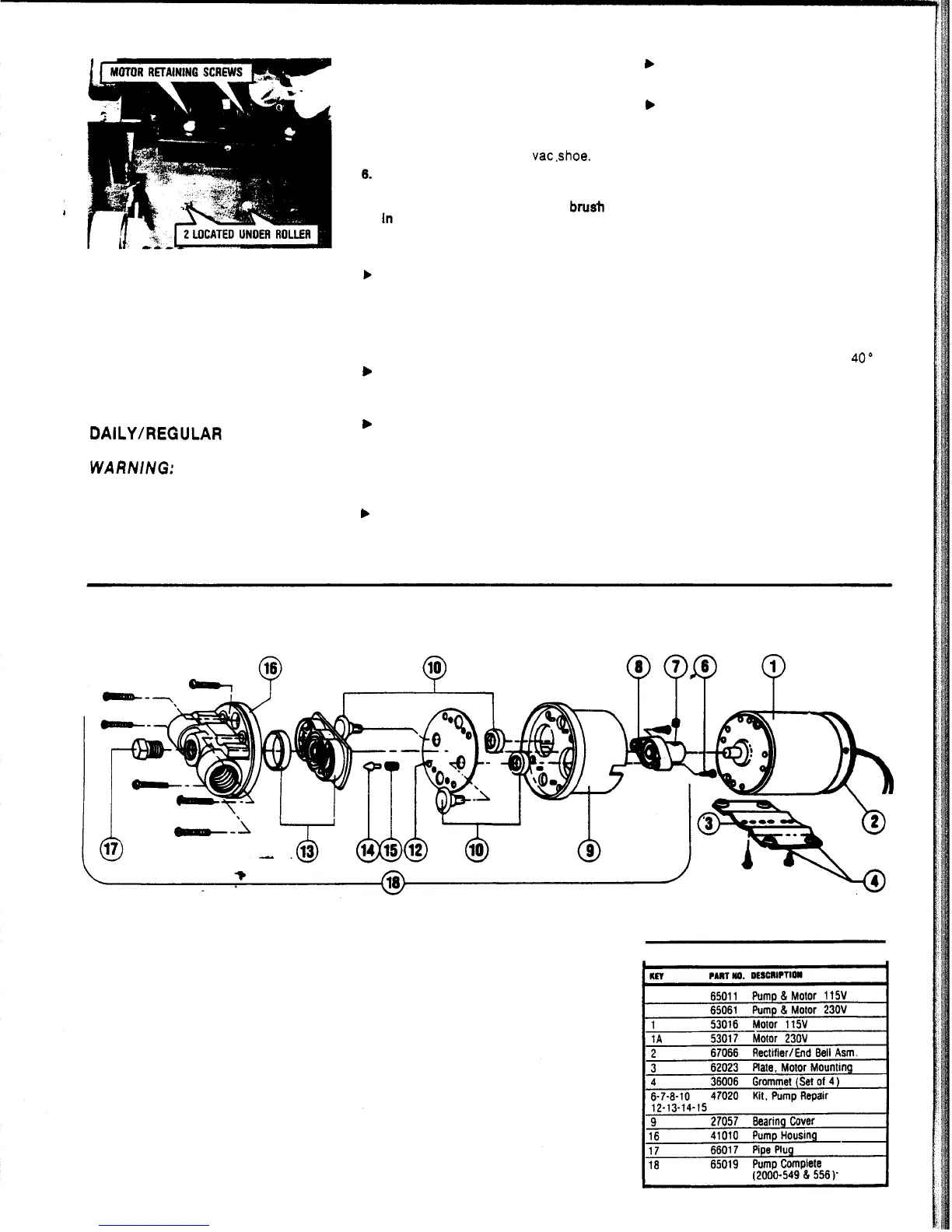

PUMP

I

PUMP PARTS LIST

I

5

Loading...

Loading...