assembly from the appliance. See Fig. 28. When refitting the

hood ensure that the rear return edge passes under the lip at the

rear of the combustion chamber.

(g) Combustion Chamber Front and Sides. Remove the inner

casing cover and flue hood assembly. Unscrew the two wing

nuts securing the front and sides and remove from the

appliance. See Fig. 28.

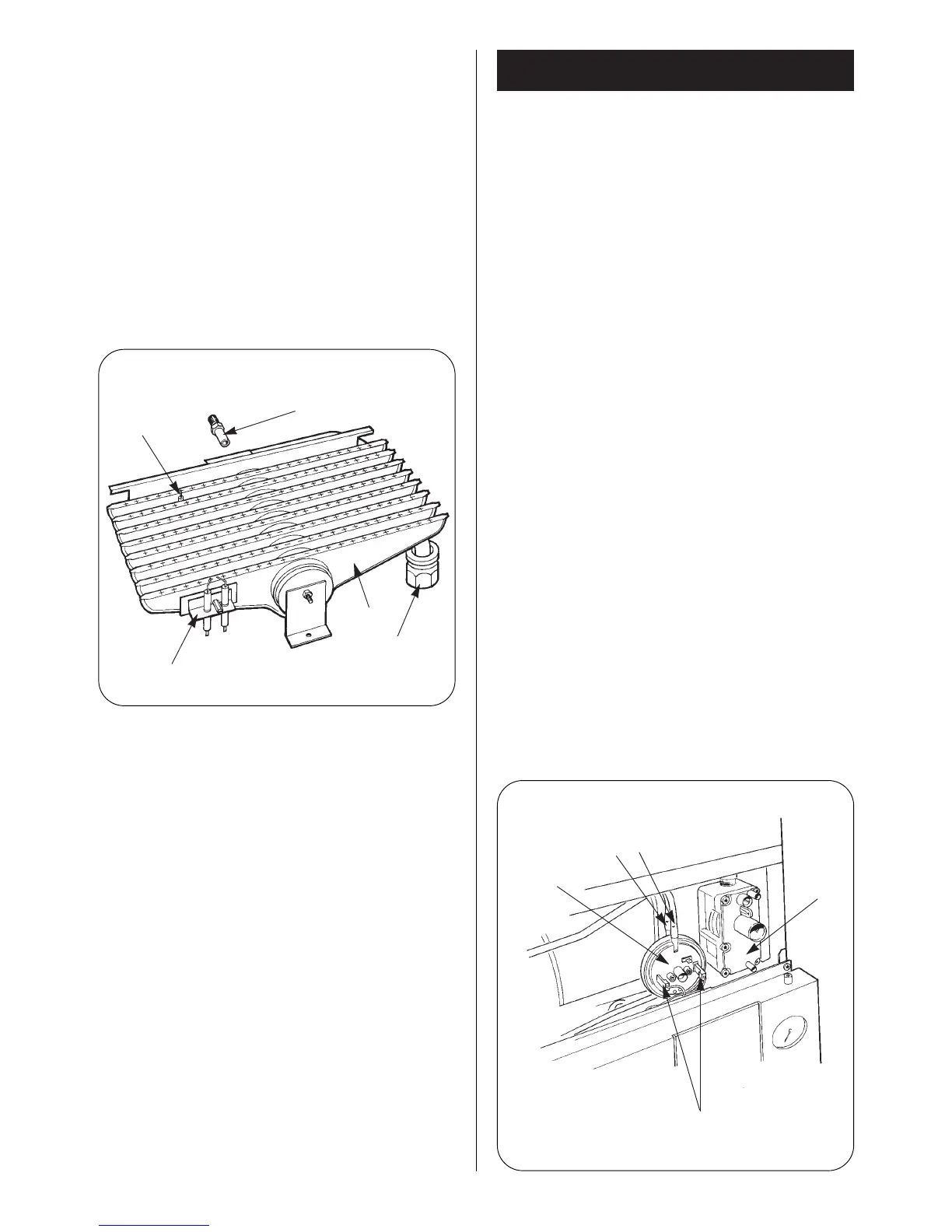

(h) Burner Assembly. Remove the combustion chamber front

and sides. Pull off the two spark electrode leads and disconnect

the flame sense lead. Undo the G

3

/

4

inch nut on top of the gas

valve. Undo the burner fixing screw. Lift up and remove the

burner assembly from the appliance.

14. 4 SERVICE OF COMPONENTS

Clean the Fan.

Any dust or fluff should be removed with a soft

brush or by blowing. Take care not to distort the pressure

sensing device.

Clean the Main Burner. Brush the blade tops and mixing tube

with a soft brush and check that all the flame ports are clear.

Remove any blockages with a non-metallic brush. Inspect the

injector and clean with a soft brush. Replace the injector if it

appears damaged. Do not use a wire brush or anything likely to

cause damage. Replace the spark and sense electrodes if they

appear damaged.

Clean the Gas to Water Heat Exchanger. Cover the burner

manifold hole in the combustion chamber bottom panel with a

cloth. Clean the heat exchanger using a soft brush. Remove the

deposits from the bottom of the combustion chamber. Do not

distort any of the blades.

Combustion Chamber Insulation. Examine and replace any

pads that are damaged. Remove any dust or deposits using a

soft brush.

Reassemble the appliance in the reverse order.

Check that all components are in place and correctly fixed. Leave

the cabinet front panel to be fitted after checking the operation

of the appliance.

14. 5 TEST THE APPLIANCE

On completion of the service and reassembly of the appliance,

check for gas soundness and the correct operation of the

appliance as described in Section 12 – Commissioning.

Refit the cabinet front panel and reset the controls to the users

requirements.

15.1 IMPORTANT

Switch off the electricity and gas supplies before replacing any

components. After the replacement of any components, check

for gas soundness where relevant and carry out functional

checks as described in Section 12 – Commissioning.

15.2 COMPONENT ACCESS

To replace components it is necessary to remove one or more

sections of the cabinet and cover plates within the appliance as

described in Section 14.3. The facia panel may also need to be

hinged down as described in Section 14.3 (c).

15.3 DRAINING THE APPLIANCE

Check that the electricity supply to the appliance is turned off.

Before removing any component holding water it is important

that as much water as possible is removed from the appliance.

(a) Central Heating Circuit. Turn off the central heating flow and

return valves at the appliance. Fit tubes to the drain taps on the

flow and return manifolds and open the drain taps about one

turn, make sure that the dust cap on the auto air vent is

loosened. See Fig. 16. Close the drain taps when the flow has

stopped. Be careful

not to overtighten the drain taps. Some

water will remain in the expansion vessel, pump, diverter valve,

water to water and Gas to Water heat exchangers and extra care

must be taken when removing these components.

(b) Domestic Hot Water Circuit. Turn off the mains cold supply

valve at the appliance and open the lowest hot water tap. A

quantity of water will remain in the Water to Water heat

exchanger and the diverter valve and extra care must be taken

when removing these components.

15.4 COMPONENT REPLACEMENT

1. Automatic Air Vent.

See Fig. 31.

Remove the inner casing cover as described in Section 14.3 (b).

Drain the central heating circuit as described in Section 15.3 (a).

Remove the circlip and lift the assembly from the appliance.

Unscrew air vent from the pipe. Check the condition of the fibre

washer.

Fit the replacement assembly, making sure the ‘O’ ring is in good

condition.

Ensure that the circlip is correctly fitted and the dust cap is

loosened.

Open the valves and fill and re-pressurise the system as

described in Section 12.2.

15. Replacement Of Parts

19

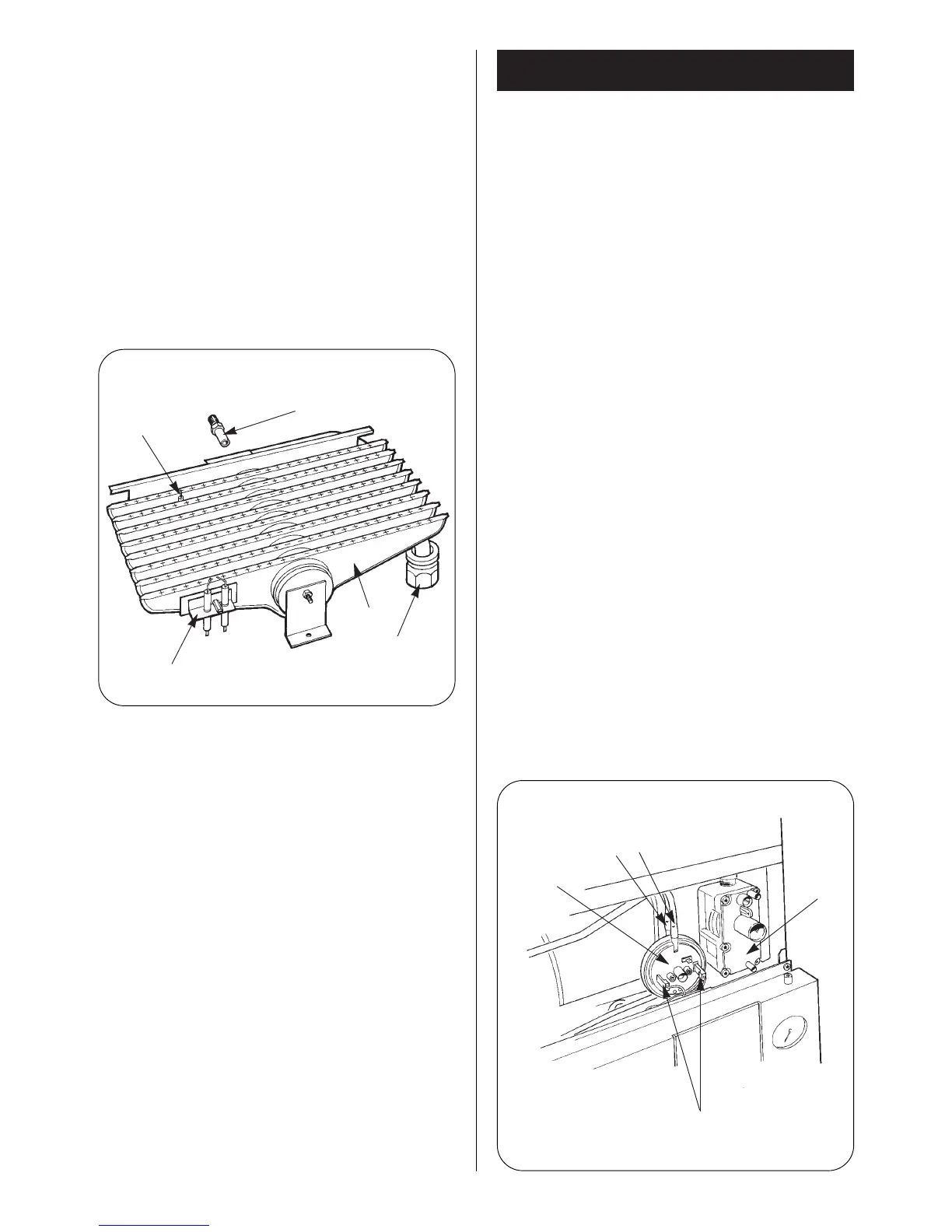

Fig. 29. Burner and electrode.

Flame sensor

Spark electrode

assembly

Burner fixing nut

Burner

Burner injector

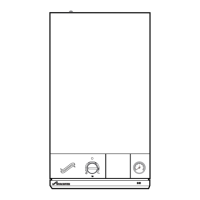

Fig. 30. Air pressure switch.

Air pressure

switch

Terminals 2 and 3

Gas valve

-

Red tube

+

Loading...

Loading...