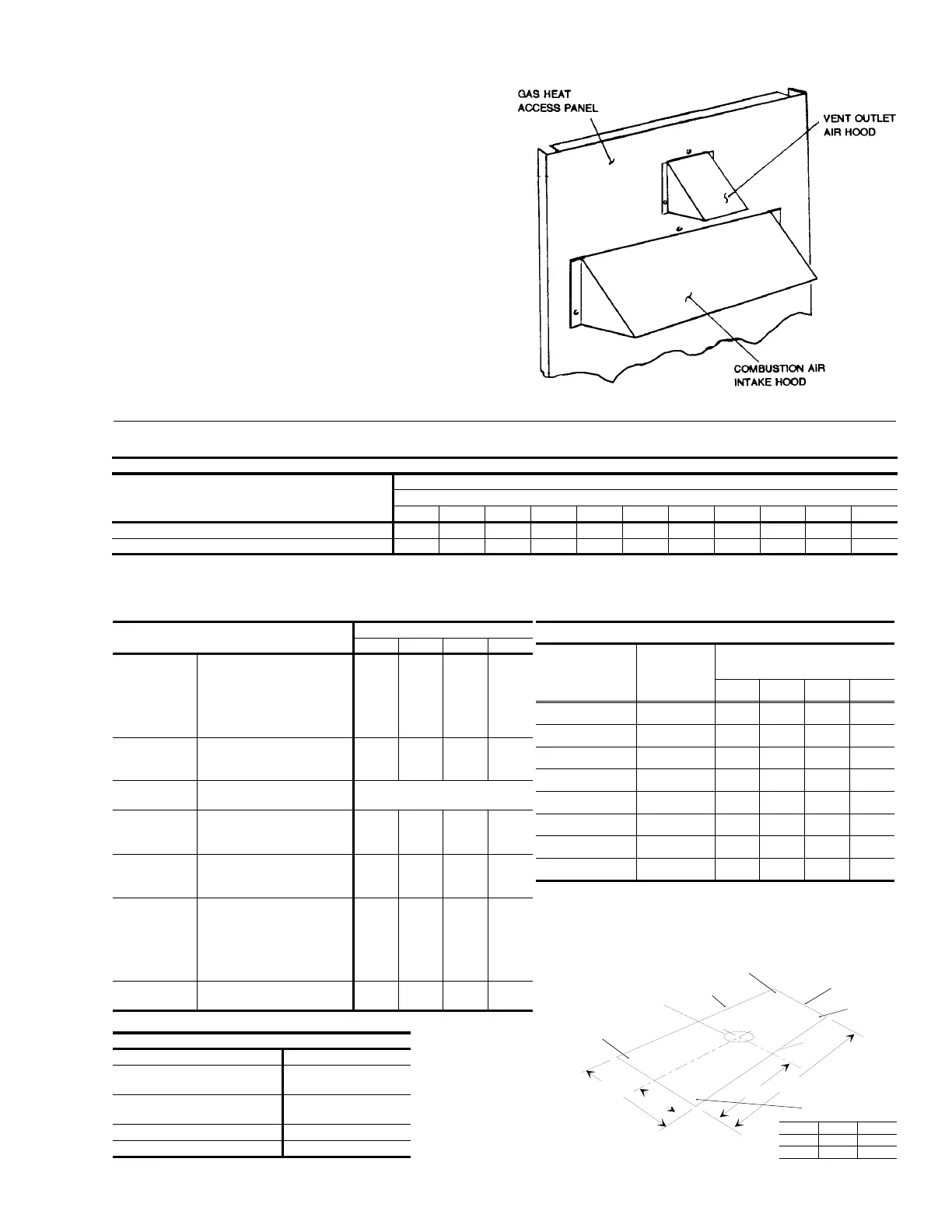

VENT AND COMBUSTION AIR HOODS

The vent and combustion air hoods are shipped attached to the

blower housing in the blower compartment. These hoods must

be installed on the outside of the gas heat access panel to

ensure proper unit function. The necessary mounting screws

are provided in a bag also attached to the blower housing.

The screen for the combustion air intake hood is secured to the

inside of the access panel opening with three fasteners and the

screws used for mounting the hood to the panel. The top flange

of this hood slips in under the top of the access panel opening

when installing. Refer to Figure 5. Remove the protective label

covering the opening just prior to installing this hood.

The vent hood (including its screen) is installed by inserting the

top flange of the hood into the slotted opening in the access

panel. The top screw secures the hood to the access panel.

The remaining two side screws must be installed after the

access panel is installed on the unit. These screws engage the

bottom flue box flange.

CAUTION: All three screws in the vent hood must be properly

installed before furnace operation to insure all com-

bustion products are exhausted from the unit.

FIG. 5

- VENT AND COMBUSTION AIR HOODS

EXTERNAL STATIC PRESSURE DROP

DESCRIPTION

RESISTANCE, IWG

CFM

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Economizer

1, 2

0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26 0.30

Bottom Duct Connections

1

0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.14 0.16 0.19 0.22

1

Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2

The pressure thru the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air duct system is less than 0.25 IWG, the unit will deliver less CFM

during full economizer operation.

TABLE 4

- STATIC RESISTANCES

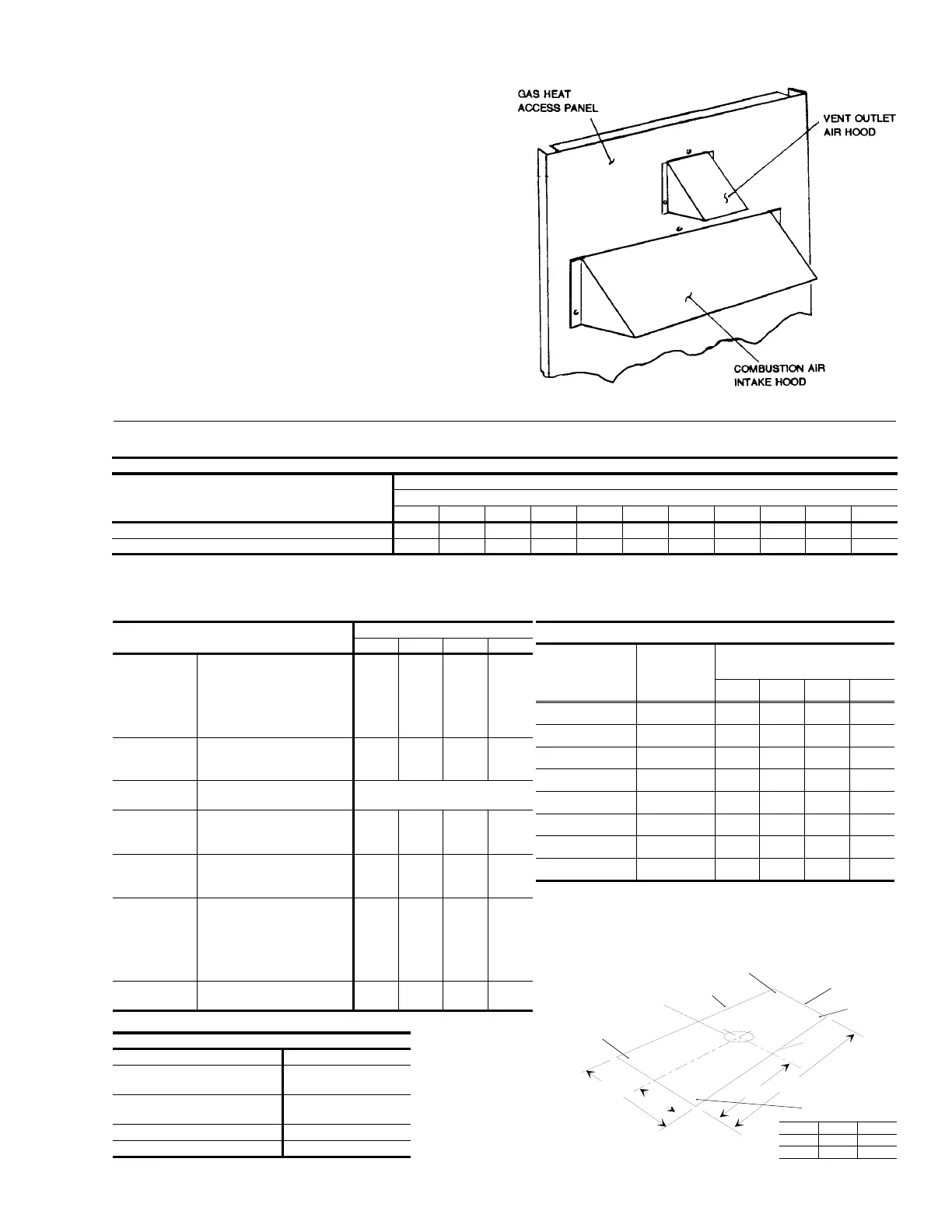

FIG 6

- CENTER OF GRAVITY

APPROXIMATE

CENTER OF

GRAVITY

FRONT

48-11/32

21

32-1/8

15-1/4

82

1

⁄

4

“

X

44

7

⁄

8

“

CONDENSER

COIL END

BACK

CORNER C

CORNER D

CORNER B

CORNER A

Y

DIM. 3-5 TON 6 TON

Y 19-3/4" 22"

X 40-3/4" 44"

WEIGHTS

UNIT

SIZE

(heat)

UNIT

WEIGHT*

(lbs.)

CORNER WEIGHTS*

(location, lbs., see figure 6)

"A" "B" "C" "D"

036 (40 Mbh) 625 180 172 133 140

036 (79 Mbh) 635 180 177 138 140

048 (60 Mbh) 675 193 185 145 152

048 (99 Mbh) 685 193 190 150 152

060 (79 Mbh) 700 200 192 150 158

060 (99 Mbh) 710 200 197 155 158

072 (79 Mbh) 775 186 209 201 179

072 (99 Mbh) 785 186 214 206 179

* Weight = Unit + Economizer

MODELS

UNIT SIZE

036 048 060 072

EVAP.

BLOWER

CENTRIFUGAL BLOWER

(Dia. x Wd. in.)

FAN MOTOR HP

(Direct-Drive)

FAN MOTOR HP

(Belt-Drive)

12 x 10

1

⁄

2

1

1

⁄

2

12 x 10

3

⁄

4

1

1

⁄

2

12 x 10

1

1

1

⁄

2

12 x 11

1

1

1

⁄

2

EVAP.

COIL

ROWS DEEP

FINS PER INCH

FACE AREA (Sq. Ft.)

3

13

3.6

3

13

4.3

3

13

5.1

4

13

5.1

COMPR.

TYPE

HERMETICALLY SEALED SCROLL TYPE

COND.

FAN

PROPELLER DIA. (in.)

FAN MOTOR HP

NOM. CFM TOTAL

24

1

⁄

4

3,400

24

1

⁄

4

3,400

24

1

⁄

4

3,400

24

1

⁄

4

3,300

COND.

COIL

ROWS DEEP

FINS PER INCH

FACE AREA (Sq. Ft.)

1

16

17.1

1

16

17.1

1

22

17.1

2

16

16.7

AIR

FILTERS

(SEE NOTE)

QUANTITY PER UNIT

(15" x 20" x 1")

QUANTITY PER UNIT

(14" X 25" X 1")

TOTAL FACE AREA

(sq. ft.)

2

1

6.3

2

1

6.3

2

1

6.3

2

1

6.3

CHARGE

REFRIGERANT 22

(lbs./oz.)

5/8 6/8 6/8 10/0

NOTE: Filter racks are adapted for 1" or 2" thick filters.

TABLE 5

- PHYSICAL DATA

OPTIONS / ACCESSORIES WEIGHTS (lbs.)

Economizer 50

Motorized Outdoor

Air Damper

26

Barometric Relief/Fixed

Outdoor Air Intake Damper

10

Roof Mounting Curb 92

Belt-Drive Blower 5

530.18-N8W

Unitary Products Group 7

Loading...

Loading...