035-15241-003 Rev. A (201)

Unitary Products Group 19

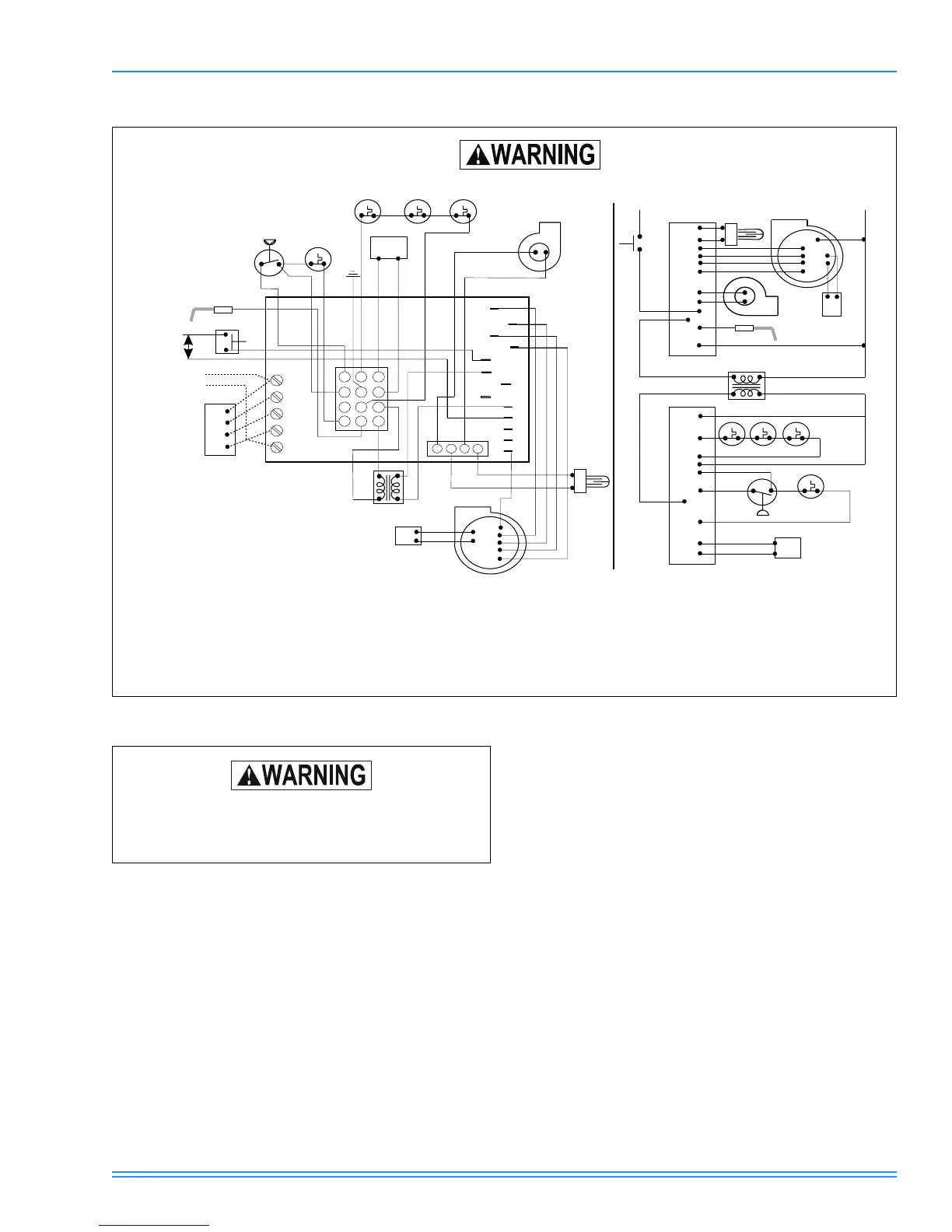

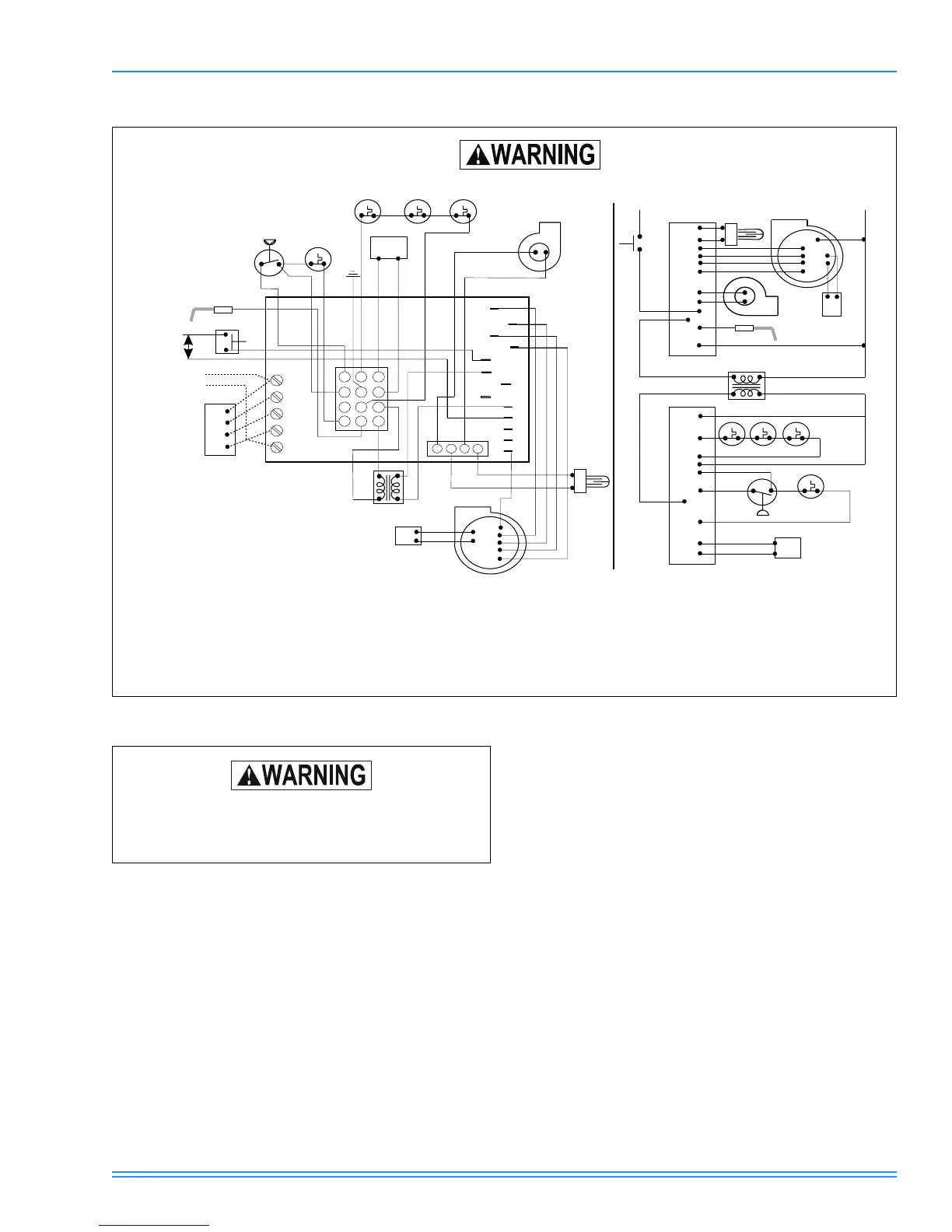

WIRING DIAGRAM

PRE-OPERATIONAL CHECKS

1. Be sure that the furnace is equipped for the type of gas

being supplied to the furnace. See unit rating plate. If LP

(propane) gas is to be used, make sure that the fur-

nace has been properly converted.

2. Manually spin circulating air blower wheel to ensure that

it turns freely and does not strike the blower housing.

3. Was the gas piping tested and/or purged of air then

checked for leaks? See instructions for gas piping. Even

the smallest leak must be eliminated before attempting

to light the furnace.

SEQUENCE OF OPERATION

These furnaces are equipped with an electric hot surface

burner ignition system. In response to a call for heat by the

room thermostat, a hot glowing ignitor lights the burners at

the beginning of each operation cycle. The burners will con-

tinue to operate until the thermostat is satisfied at which time

all burner flame is extinguished. During the off cycle no gas is

consumed. With the room thermostat set below room temper-

ature and with the electrical power and gas supply to the fur-

nace on, the normal sequence of operation is as follows:

1. When the room temperature falls below the setting of the

room thermostat, the thermostat energizes the furnace

control board.

2. When the furnace control board is activated, the vent

blower is turned on. A circuit is also made through the

normally open pressure switch contacts.

3. As the vent blower increases in speed, the contacts of

the pressure switch will close and complete the electrical

circuit to the ignitor.

4. During the next 30 seconds, the vent blower will bring

fresh air into the heat exchanger and the ignitor will

begin to glow. At the end of this period, the gas valve will

open and the burners will light.

5. After the burners light, a separate sensor acts as a flame

probe to check for the presence of flame. As long as a

flame is present, the system will monitor it and hold the

gas valve open.

DISCONNECT THE ELECTRIC POWER BEFORE SERVICING.

BDSS

ROS

LS

PS

T’STAT

= Blower Door Safety Switch

= Rollout Switch

= Limit Switch

= Pressure Switch

= Wall thermostat

XFMR

IGN

CAP

VM

GV

FS

= Transformer

= Hot Surface Ignitor

= Capacitor

= Vent Motor

= Gas Valve

= Flame Sensor

PS

FS

LS

ROS

VM

IGN

BLOWER

BLOWER

T’STAT

TO

A/C

BDSS

CAP

115V

XFMR

ROS ROS ROS

PS

LS

GV

CAP

COM

HI

MH

ML

LO

BRN

BRN

XFMR

115V

COM

HI

MH

ML

LO

VM

FS

24V

P-2B

P-4B

P-1B

P-3B

L1

XFMR

P-2A

NEU

IGN

P-6A

P-5A

P-11A

P-8A

P-7A

P-10A

P-3A

P-1A

P-9A

P-12A

HUM

EAC

XFMR

L1

PARK

PARK

HEAT

COOL

B

10

1

2

3

4

5

6

7

8

9

11

12

BLK

WHT

BLK

YEL

RED RED

ROS

ROS

GV

PUR

PUR

Y

W

R

G

Y

W

R

G

C

1

2

3

BLU

BLU

A

ORG

ORG

GRN

GRY

24V

115V

BLK

WHT

RED

YEL

BLU

RED

RED

BRN

BRN

RED

PUR

PUR

4

COOL

PARK

PARK

HEAT

NEUTRALS

Factory internal wiring shown solid. If any of the original

wire supplied with this unit must be replaced, it must be

replaced with Type 105º C thermoplastic or its equivalent.

SHOCK HAZARD - Be sure electrical power to

furnace is turned off before performing the pre-

operational checks.

Loading...

Loading...