258919-UIM-B-0107

2

INSPECTION

INSPECTIONINSPECTION

INSPECTION

As soon as a coil is received, it should be inspected for possible dam-

age during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information. Check drain pan for cracks or break-

age.

CLEARANCES

CLEARANCESCLEARANCES

CLEARANCES

During Installation

Clearance must be provided for:

1. Refrigerant piping and connections

2. Maintenance and servicing access - including cleaning the coil

3. Condensate drain line

4. Filter removal / change

5. Removal of coil assembly

LIMITATIONS

LIMITATIONSLIMITATIONS

LIMITATIONS

These coils should be installed in accordance with all national and local

safety codes. Check Tables 2, 3, and 4 for operating limitations.

SECTION III: COIL METERING DEVICES

SECTION III: COIL METERING DEVICESSECTION III: COIL METERING DEVICES

SECTION III: COIL METERING DEVICES

If the model number is of the following format: *****2A**, *****2B**

or *****2C** - The coil will have an R22 TXV metering device installed at

the factory.

If the model number is of the following model series:

*****3X** - The coil will require a TXV to be installed in the field. Refer to

installation manual with TXV kit. It is recommended to install the TXV kit

prior to installation of coil and brazing line sets.

TXV METERING DEVICE

TXV METERING DEVICETXV METERING DEVICE

TXV METERING DEVICE

Please refer to Tables 1-3 to verify proper and recommended line set

sizes and that this is a valid system match for the AC or HP unit

installed.

The temperature sensing bulb should be attached to the suction line

set. Refer to Figure 3.

NOTE: For models that have factory installed TXV’s, take caution not to

apply high temperatures to the TXV assembly or equalizer line while

brazing.

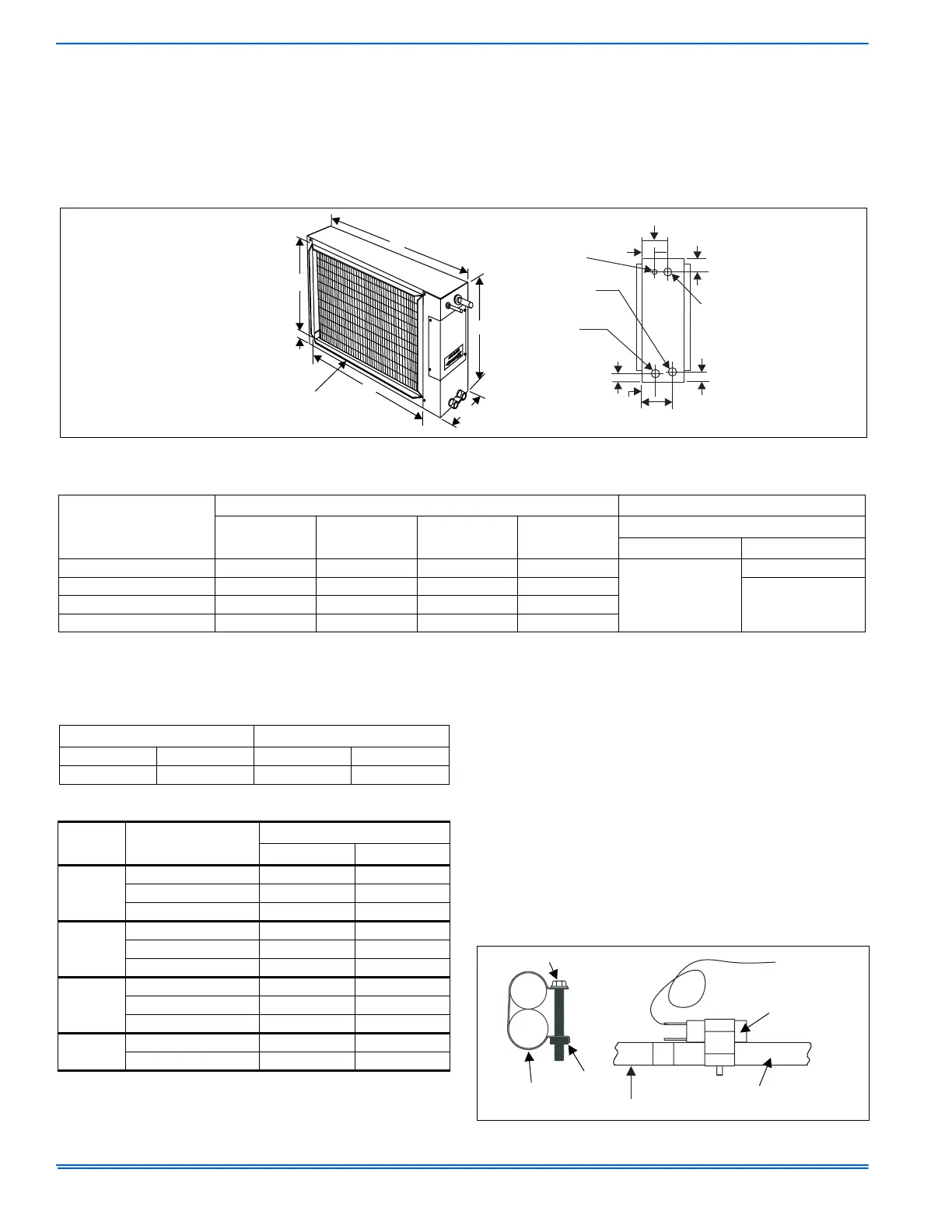

FIGURE 2: Coil - HD

1-3/4

C

5-5/8

B

A

D

3-3/4

2-5/8

1-3/8

VAPOR

CONN.

LIQUID

CONN.

3/4 NPT

SECONDARY

DRAIN CONN.

3/4 NPT

PRIMARY

DRAIN CONN.

7/8

1-7/8

4-1/8

1-3/8

OUTLET SAME

SIZE AS INLET

(3/4” FLANGE)

TABLE 1:

Dimensions

Model

Dimensions - Inches Refrigerant Connections

A B C D

Line Size

Liquid Vapor

HD24S**H1 28-3/4 24 23-3/4 21-5/8

3/8

3/4

HD36S**H1 28-3/4 28 23-3/4 25-5/8

7/8HD48S**H1 34-3/4 28 29-3/4 25-5/8

HD60S**H1 34-3/4 30 29-3/4 27-5/8

TABLE 2:

Entering Air Temperature Limits

WET BULB TEMP. (°F) DRY BULB TEMP. (°F)

MIN. MAX. MIN. MAX.

57 72 65 95

TABLE 3:

Coil Air Flow Limits

Coil

Size

Outdoor Unit

Tons

CFM Limits

Minimum Maximum

24

1 350 450

1-1/2 525 675

2 700 900

36

2 700 900

2-1/2 875 1125

3 1050 1250

48

3 1050 1250

3-1/2 1225 1575

4 1400 1750

60

4 1400 1750

5 1750 2200

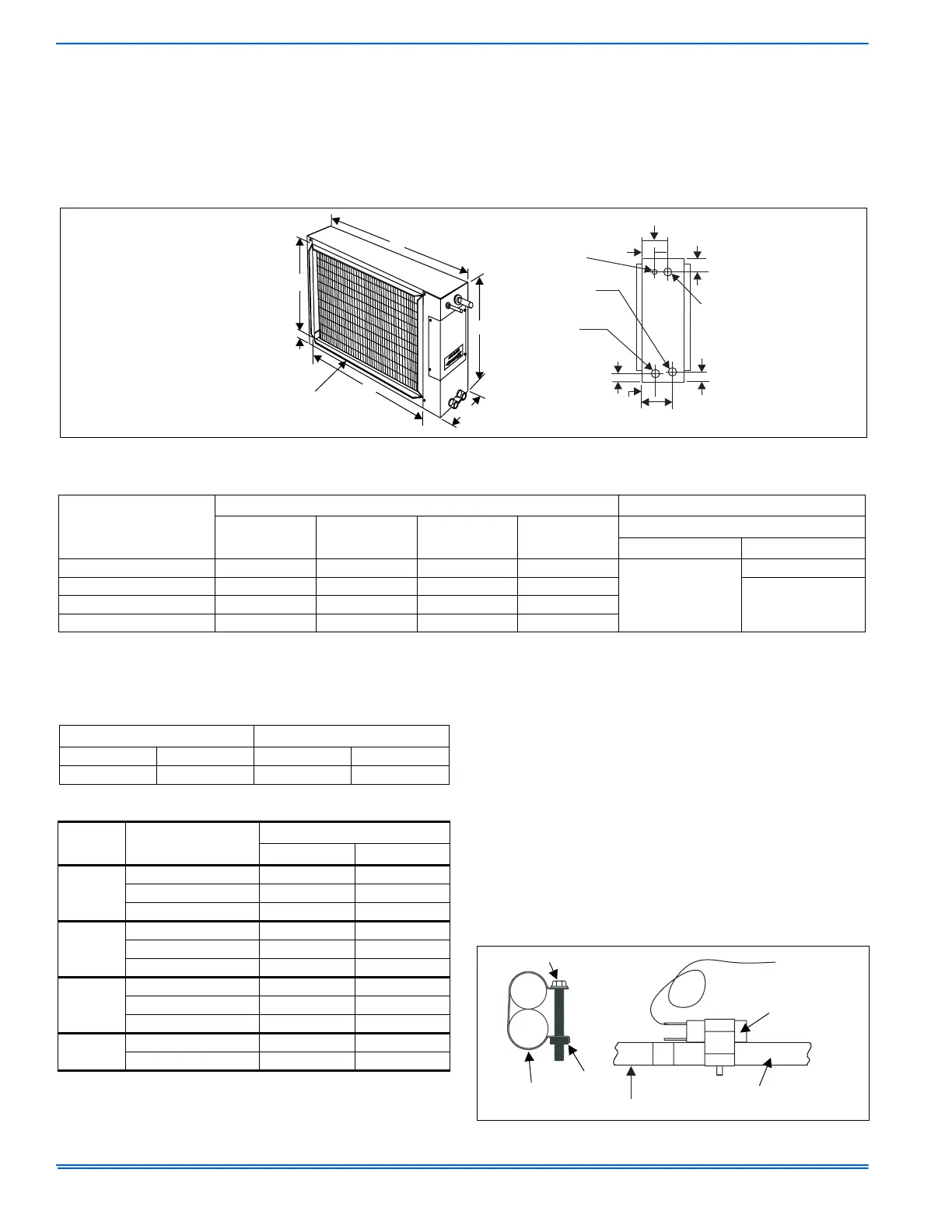

FIGURE 3:

Proper Bulb Location

TXV BULB

(Cover completely

with insulation)

SCREW

CLAMP

NUT

SUCTION HEADER

SUCTION LINE

(FIELD INSTALLED)

Loading...

Loading...