heat pump CFM selections. Find the recommended system air-

flow in the table for the installed Air Handler model.

Moving up the table, identify the “COOL” tap jumper position (“A”,

“B”, “C” or No Jumper). Go to the connector board and set the

jumper horizontally for the “COOL” tap position. See Figure 8 for

the layout of the connector board.

NOTE: No jumper indicates the jumper should be removed or

placed in the “store” position (see Figure 8).

Return to Table 1 and move to the right to identify the “ADJ” tap

jumper position. Go to the connector board and set the jumper

horizontally for the “ADJ” tap position (refer to Figure 8). Again,

“No jumper” indicates the jumper should be removed or placed in

the “store” position.

To Set Heat Pump CFM:

The heat pump CFM setting is the same as the cooling CFM. No

additional CFM setting is required, however, you must remove the

jumper at the bottom of the connector board labeled “Remove for

Heat Pump” for heat pump operation. (See Figure 8.)

To Set Electric Heat CFM:

The blower speed required for the Electric Heat is different than

cooling. Refer to the label on the blower housing or Table 1 for the

possible CFM selections. Refer to Table 4 for the minimum

required CFM for the electric heater installed. Find the desired

airflow in Table 1. Moving up the table, identify the “HEAT” tap

jumper position. Go to the connector board and set the jumper

horizontally for the “HEAT” tap position.

CAUTION: DO NOT change the “ADJ” tap position on the con-

nector board as this will change your cooling CFM

previously selected.

To Set Delay Profile:

Every variable speed air handler has multiple “blower off delay”

profiles to optimize system performance and efficiency.

Refer to Table below for the type of system installed. set the

“DELAY” jumper tap position horizontally on the connector board

for the appropriate setting.

To Install Humidistat Accessory:

If the system is used with a humidistat accessory, connect the field

wires to screw terminals “R” and “BK” on the connector board.

See Figures 10 or 11.

IMPORTANT: Remove the jumper at the bottom of the connector

board marked “Remove for Humidistat” for humidistat operation.

MAINTENANCE

One permanent high velocity washable filter is provided with each

filter rack. This filter may be cleaned with a vacuum cleaner or

washed with warm water using a mild detergent. Do not use a

high velocity water stream. No coating is required. Install filter with

cloth mesh towards blower. Never turn a dirty filter to allow air flow

in the opposite direction.

Filters must be cleaned when they become dirty. Inspect at least

once per month. The frequency of cleaning depends upon the

hours of operation and the local atmospheric conditions. Clean

filters keep unit efficiency high.

COIL CLEANING

If the coil needs to be cleaned, it should be washed with Calgon

Coilclean (mix one part Coilclean to seven parts water). Allow

solution to remain on coil for 30 minutes before rinsing with clean

water. Solution should not be permitted to come in contact with

painted surfaces.

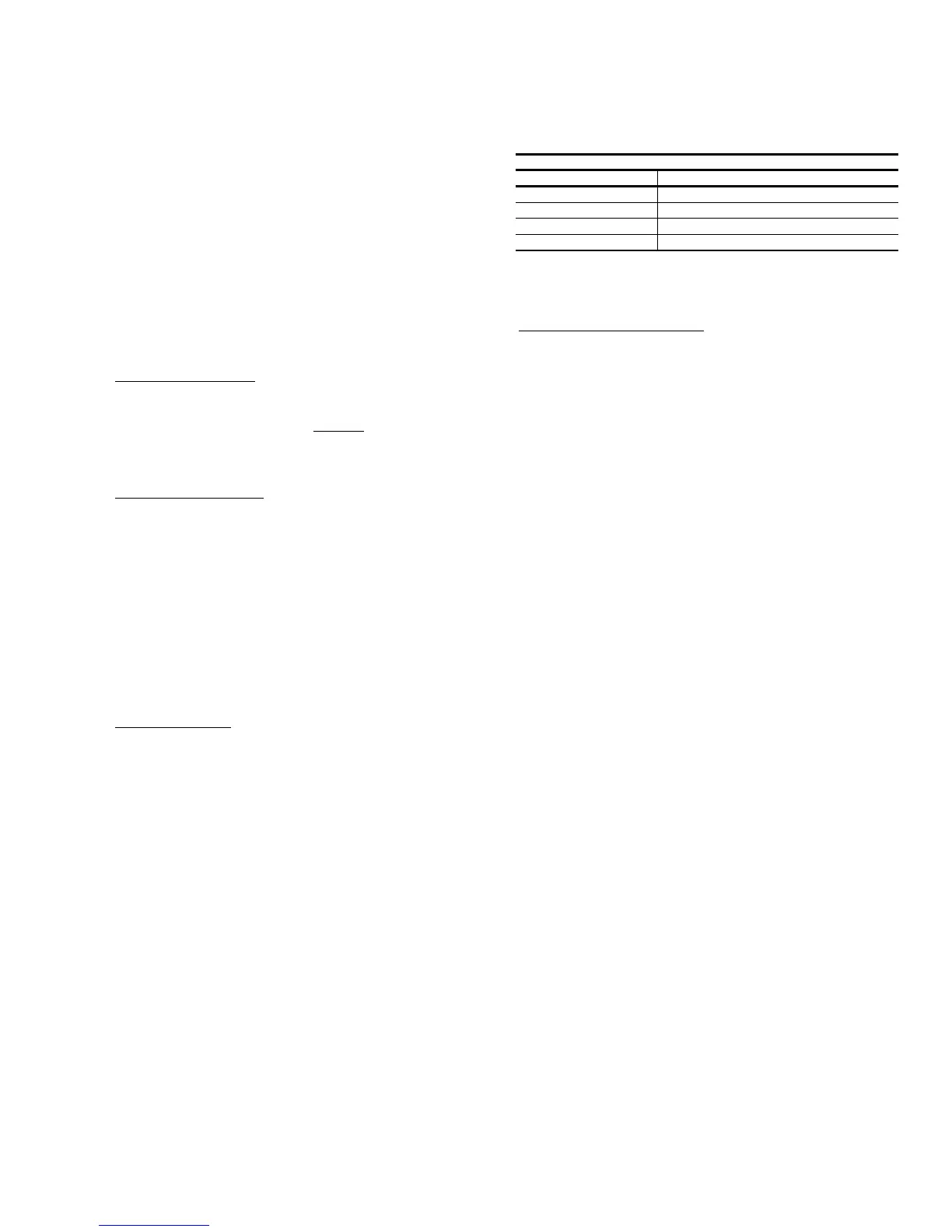

Delay Profile

“DELAY” Tap Unit Type

Jumper at “A” System wo/TXV or wo/ S.V.

Jumper at “B” System w/TXV or w/ S.V.

Jumper at “C” Two Stage Condensor

No Jumper Test Mode

TXV= Thermal Expansion Valve

SV= Solenoid Valve

535.03-N1Y

Unitary Products Group 7

Loading...

Loading...