YORK INTERNATIONAL

6

AUTOMATIC SPEED CONTROL

The Micro Board controls the VSOP drive output fre-

quency by applying a Pulse Width Modulation (PWM)

speed command signal to the VSOP drive (ref Fig. 2).

The signal is applied every 0.7 seconds. Within the 0.7

second period, the duration of time that the signal is

“low” (0VDC) , determines the VSD output frequency

between 25 to 60Hz. If the signal remains “high”

(+12VDC) for the entire 0.7 second period, it is com-

manding the VSOP drive’s output frequency to 25Hz.

If the signal is low for the entire 0.7 second period, it is

commanding the VSOP drive’s output frequency to

60Hz. Frequencies between these extremes are

achieved by driving the signal low for a proportionate

amount of time within the 0.7 second period. For ex-

ample, if the signal is low for 50% (0.35 seconds) of the

0.7 second period, it would be commanding the VSOP

drive to operate at a frequency that is halfway between

25 and 60Hz, or 42.5Hz. The resolution, or smallest in-

crement of change, is 0.01 seconds. This allows the

output frequency to be changed in 0.5 Hz steps. The

formula provided in Figure 2 can be used to calculate

the output frequency for a given PWM signal.

The entire VSOP drive run time is divided into “Oil

Pressure Control Periods”. They run consecutively

and continuously; when the first one ends, the next one

begins. This repeats until the oil pump is shut down.

The duration of the periods are determined by the “OIL

PRS CTRL PERIOD SETPOINT”, programmed by

the Service Technician using instructions under “Pro-

gramming”. This setpoint is programmed in multiples

of 0.3 seconds over the range of 0.3 to 2.7 seconds, by

programming a “MULTIPLIER” value of 1 through 9.

The program multiplies this value by 0.3 to produce pe-

riods over the range of 0.3 to 2.7 seconds. This multi-

plier value also determines the magnitude of output fre-

quency correction when the error between the actual

oil pressure and the oil pressure setpoint is > ± 6 PSID).

The programmed value (1 through 9) is multiplied by

0.5Hz to provide greater frequency change to more

quickly correct the oil pressure. If the error is > ±0.5

PSID & <± 6 PSID, the output frequency is increased

or decreased 0.5Hz. At the end of each period, the ac-

tual oil pressure is compared to the programmed Oil

Pressure Setpoint and the Micro Board changes the

speed command as required per the following:

If actual oil pressure is:

a. >(setpoint + 0.5 PSID) &

<(setpoint + 6 PSID),

decrease output frequency 0.5Hz.

b. >(setpoint + 6 PSID), decrease output frequency

0.5Hz x Control Period Multiplier.

c. <(setpoint – 0.5 PSID) &

>(setpoint – 6 PSID),

increase output frequency 0.5Hz.

d. <(setpoint – 6 PSID), increase output frequency

0.5Hz x Control Period multiplier.

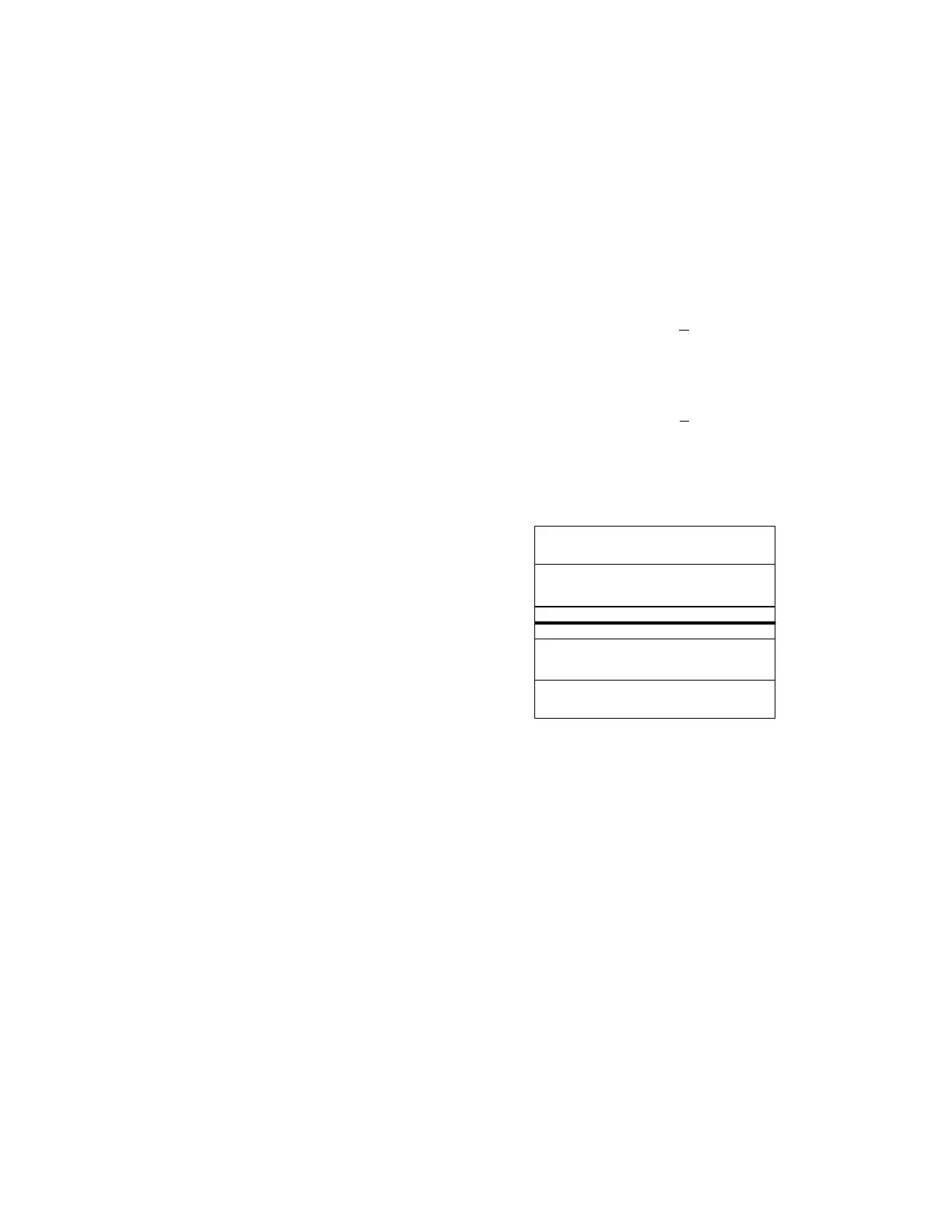

- 6 PSID

- .5 PSID

+ .5 PSID

+ 6 PSID

OIL PRESSURE

SETPOINT

CONDITION 'B' DECREASE OUTPUT FREQUENCY

0.5HZ x CONTROL PERIOD MULTIPLER

CONDITION 'A' DECREASE OUTPUT FREQUENCY

0.5HZ

NO CHANGE IN OUTPUT FREQUENCY

NO CHANGE IN OUTPUT FREQUENCY

CONDITION 'C' INCREASE OUTPUT FREQUENCY

0.5HZ

CONDITION 'D' INCREASE OUTPUT FREQUENCY

0.5HZ x CONTROL PERIOD MULTIPLER

VSOP DRIVE OUTPUT FREQUENCY CONTROL

ACTUAL OIL

PRESSURE

Since this EPROM version can be used on chillers that

are equipped with the VSOP drive and those that are

not, VSOP drive control must be enabled or disabled, as

appropriate, and the associated setpoints programmed

using the “Programming” procedure on page 8.

LD04651

Loading...

Loading...