34 Maintenance and fault tracing

The person responsible for the design of the complete safety function should also note the

Recommendation of Use CNB/M/11.050 published by the European co-ordination of

Notified Bodies concerning dual-channel safety-related systems with electromechanical

outputs:

• When the safety integrity requirement for the safety function is SIL 3 or PL e (cat. 3 or

4), the proof test for the function must be performed at least every month.

• When the safety integrity requirement for the safety function is SIL 2 (HFT = 1) or PL d

(cat. 3), the proof test for the function must be performed at least every 12 months.

This is a recommendation and depends on the required (not achieved) SIL/PL. For

example, safety relays, contactor relays, emergency stop buttons, switches etc. are

typically safety devices which contain electromechanical outputs. The STO circuit of the

inverter unit does not contain any electromechanical components.

Competence

The maintenance and proof test activities of the safety function must be carried out by a

competent person with adequate expertise and knowledge of the safety function as well as

functional safety, as required by IEC 61508-1 clause 6.

Fault tracing

Warning messages generated by the drive

Fault messages generated by the drive

Any failures of the Safe torque off function must be reported to ABB.

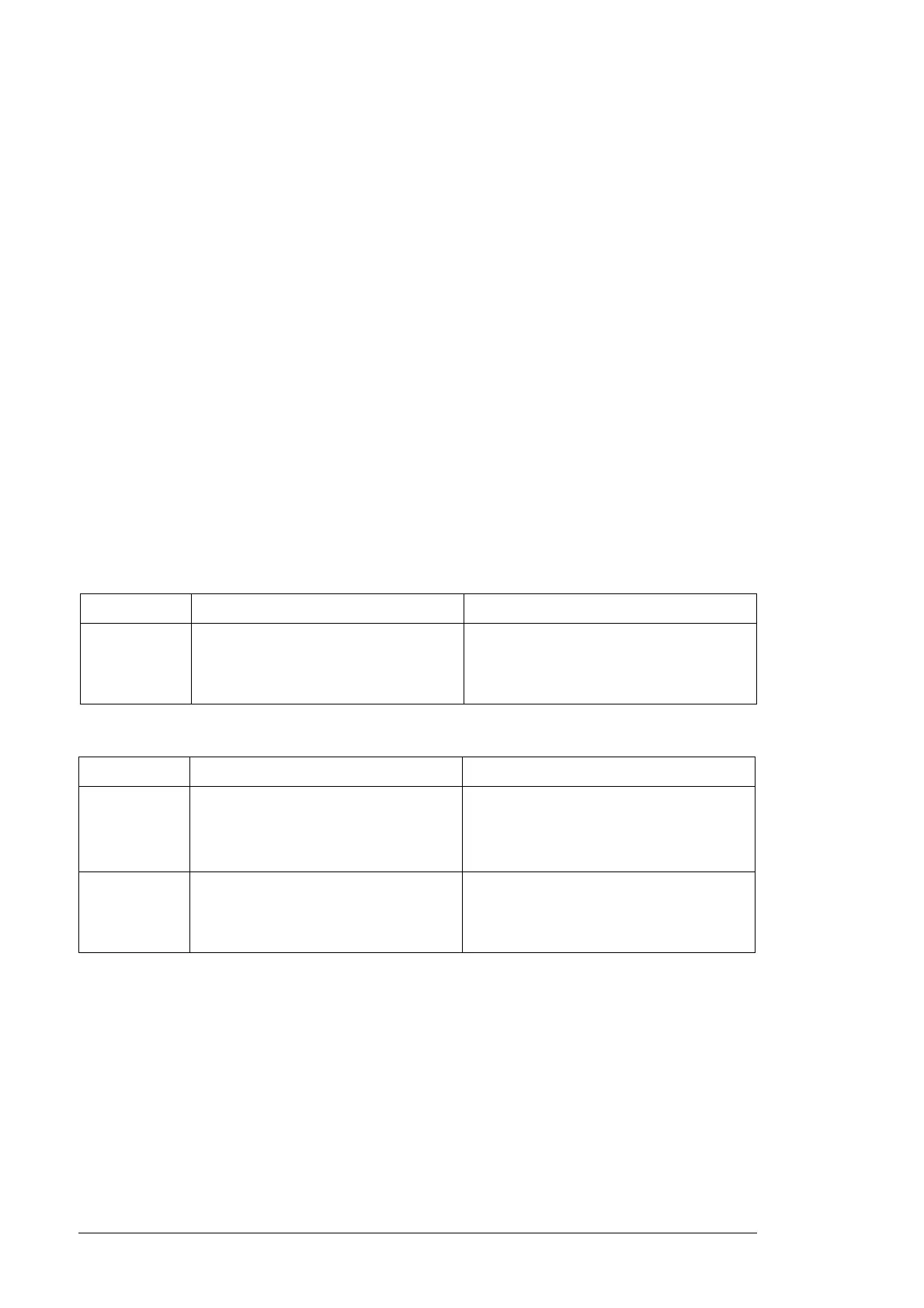

Warning Cause What to do

START INHIBI Safe torque off function has been

activated while the drive was stopped.

Close Safe torque off function switch. If the

switch is closed and the warning is still

active, check power supply at ASTO board

input terminals. Replace ASTO board.

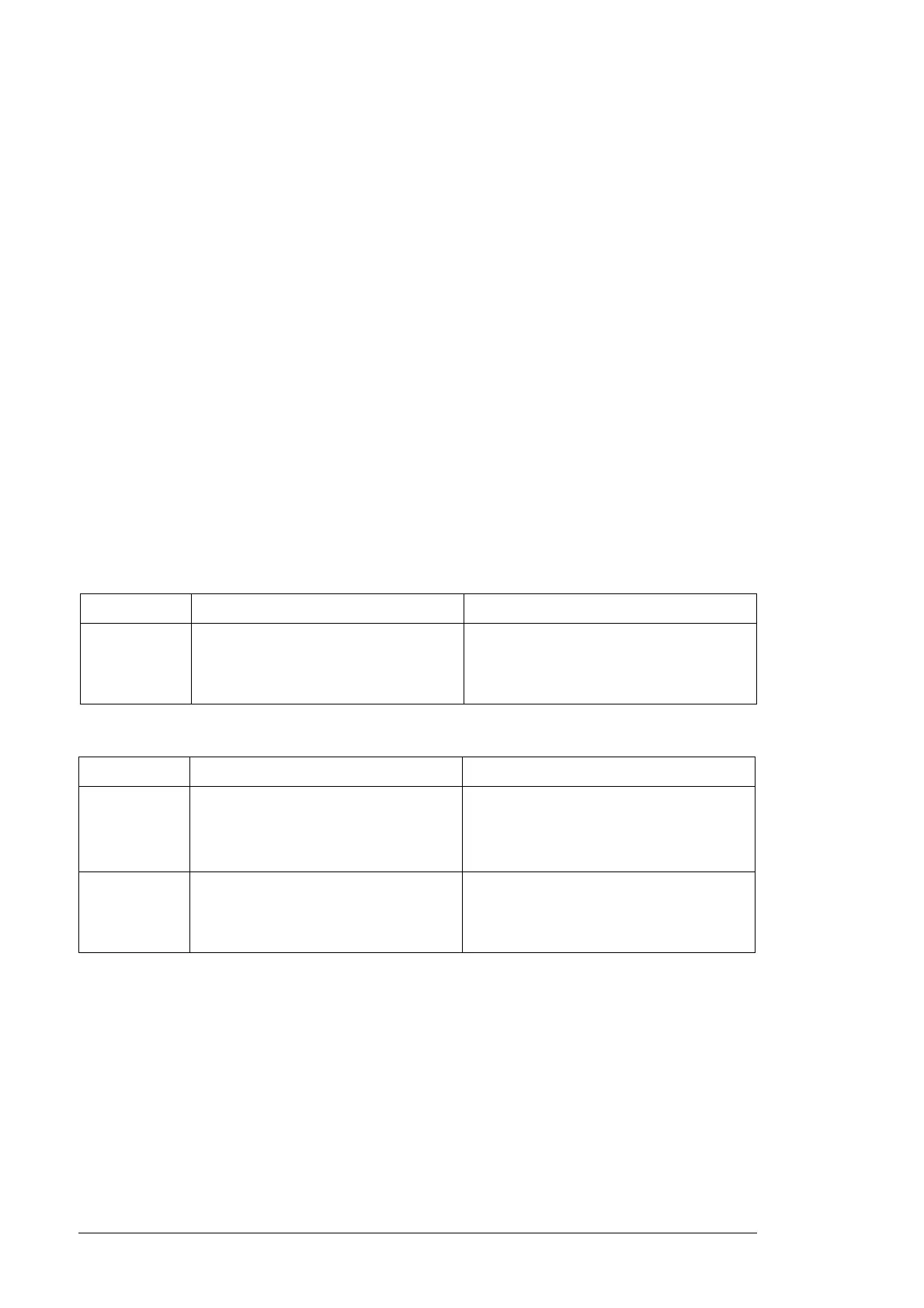

Fault Cause What to do

GD

DISABLED X

ASTO board power supply of parallel-

connected R8i inverter module has been

switched off during run. X (1…12) refers

to inverter module number.

Check Safe torque off function circuit of this

module (X).

Replace ASTO board of R8i inverter

module.

START INHIBI Safe torque off has been activated during

motor run or motor start command has

been given when Safe torque off is

active.

Close Safe torque off function switch. If the

switch is closed and the fault is still active,

check power supply at ASTO board input

terminals. Replace ASTO board.

Loading...

Loading...