DELIVERY INSPECTION AND ACCEPTANCE/SHIPPING AND STORAGE 11

—

4. Shipping and storage

Place a minimum of one standard packet of

desiccant bags inside the packing. Replace the

bags approximately every 6 months.

If the original packing no longer be available and

immediate installation is not possible, store in a

covered, well-ventilated, dry, dust-free, non-corrosive

—

3. Delivery inspection and acceptance

The following precautions must be taken during

contactor handling:

• Keep the contactor in the upright position.

• Make sure that the load is balanced on the truck

or on the transport plate/pallet

• Place protective material between the contactor

and the truck to avoid any damage or scratches

• Fix the contactor onto the truck or the transport

plate/pallet to prevent it moving or overturning

• Avoid excessive speed, sudden starts and stops

or sharp changes in direction during contactor

handling

• Only lift the contactor enough to avoid any

obstacles on the floor

• Take care to avoid any impacts with structures,

other apparatus or with personnel when handling

the contactor

• Never lift a contactor over an area where

personnel are present

• Ensure that no force is applied to insulating parts

or terminals of the contactor during handling of

the apparatus

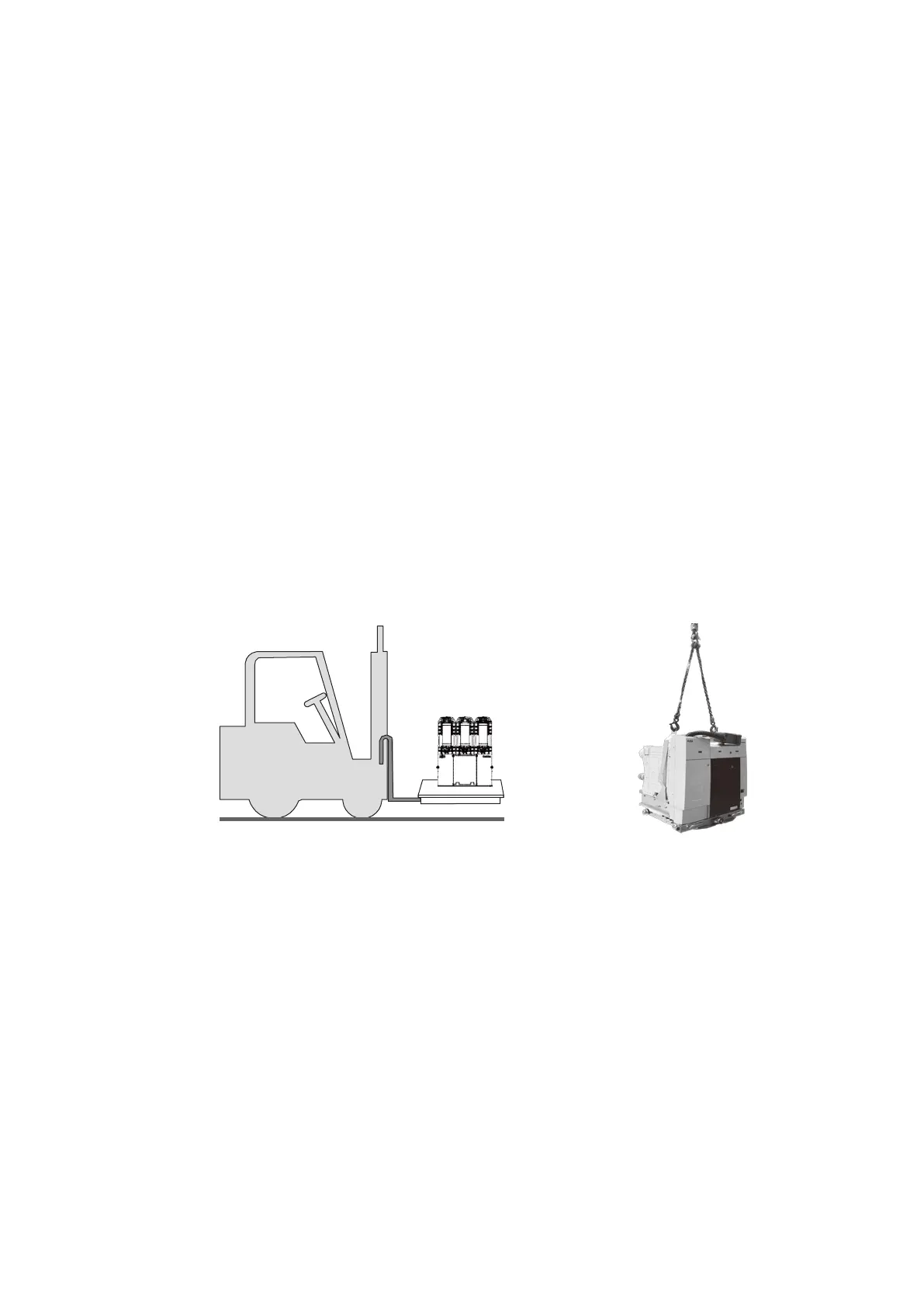

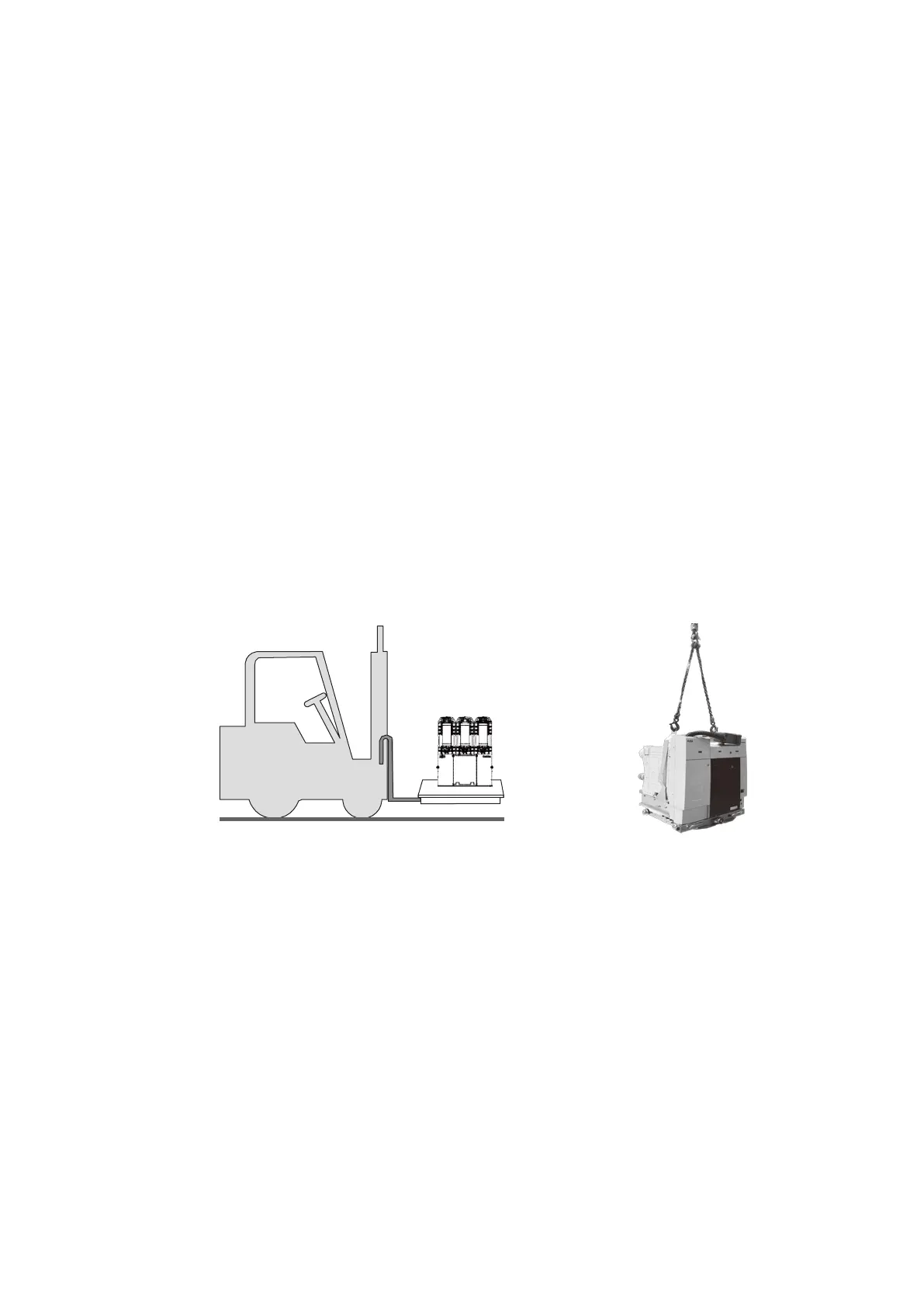

3.1 Handling using a lifting or fork-lift truck. (Fig 3a)

3.2 Handling and lifting using a crane

• Insert the lifting plates

• Lift

• Remove the lifting plates after lifting operation

finish

—

Fig 3a

ambient, with a dry atmosphere, away from any

flammable materials and at a temperature

between -15 °C and +40 °C.

In any case, avoid any accidental impacts or

positioning which stresses the structure of the

apparatus.

Loading...

Loading...