1ZSE 5492-124 en, Rev. 6 | Maintenance guide UCG 23

3.17.5 Restoring the gas cushion

Check the oil level in the oil conservator one month after

oil filling. If the oil level is lower now than when the oil filling

was finished (correct for temperature differencies!) and no

leakages are observed, the gas cushion has been solved in

the oil and has to be restored.

The procedure below is used for on-load tap-changers

without oil filter unit for continuous oil filtration. In case the

on-load tap-changer is equipped with an oil filter unit for

continuous oil filtration from ABB, and it is installed according

to our recommendations, follow the instructions in the oil filter

unit manual.

In case the on-load tap-changer consists of more than one

unit, do the restoring in one unit at a time.

WARNING

The oil in the diverter switch housing may be hot. Be

cautious!

WARNING

Before any work is carried out on the on-load

tap-changer: Make sure that the transformer is

disconnected and that earthing is properly carried

out. Obtain a signed certificate from the engineer in

charge.

CAUTION

To operate the on-load tap-changer with a too small

or no gas cushion means a risk for a trip of the

pressure relay.

Procedure

1. Close the valve in the tube to the conservator.

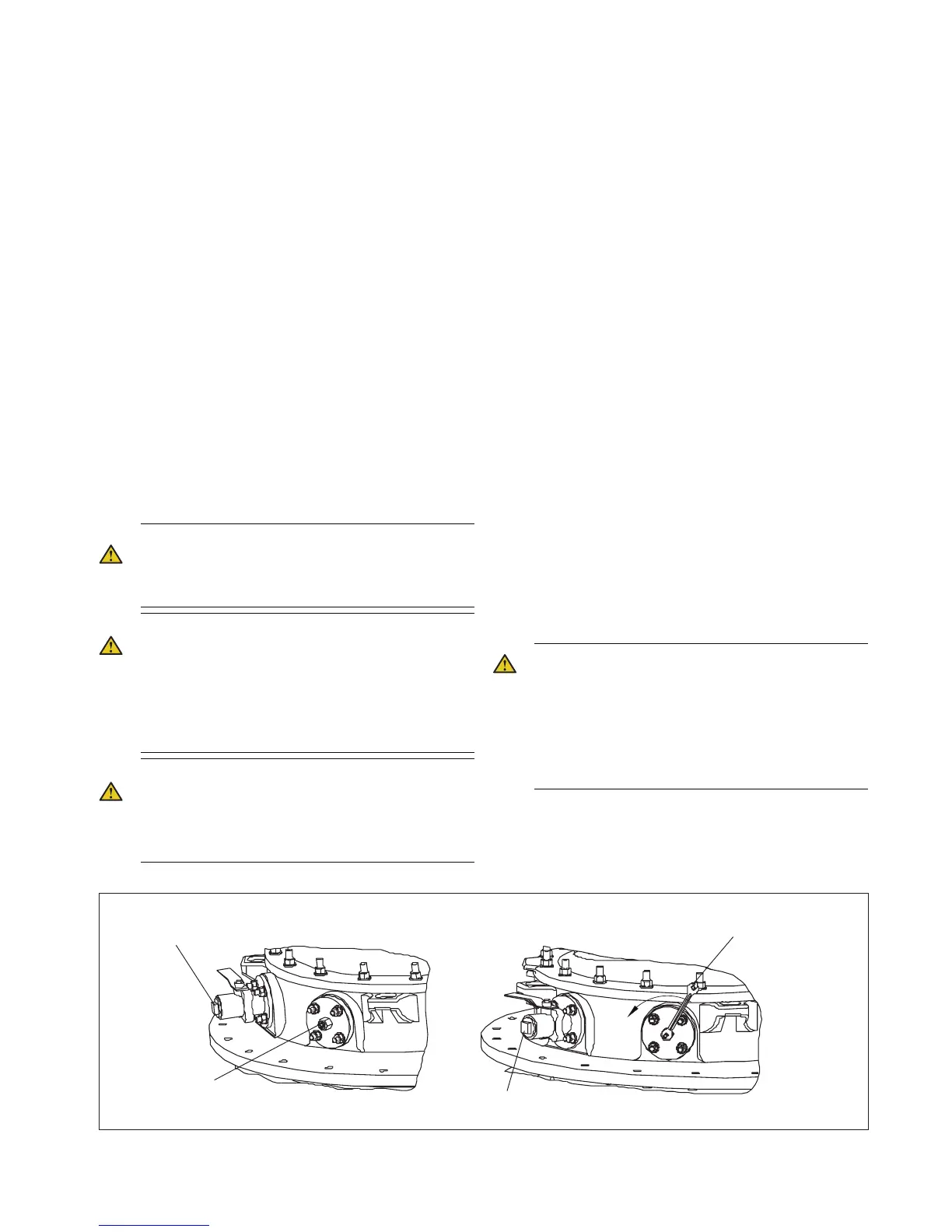

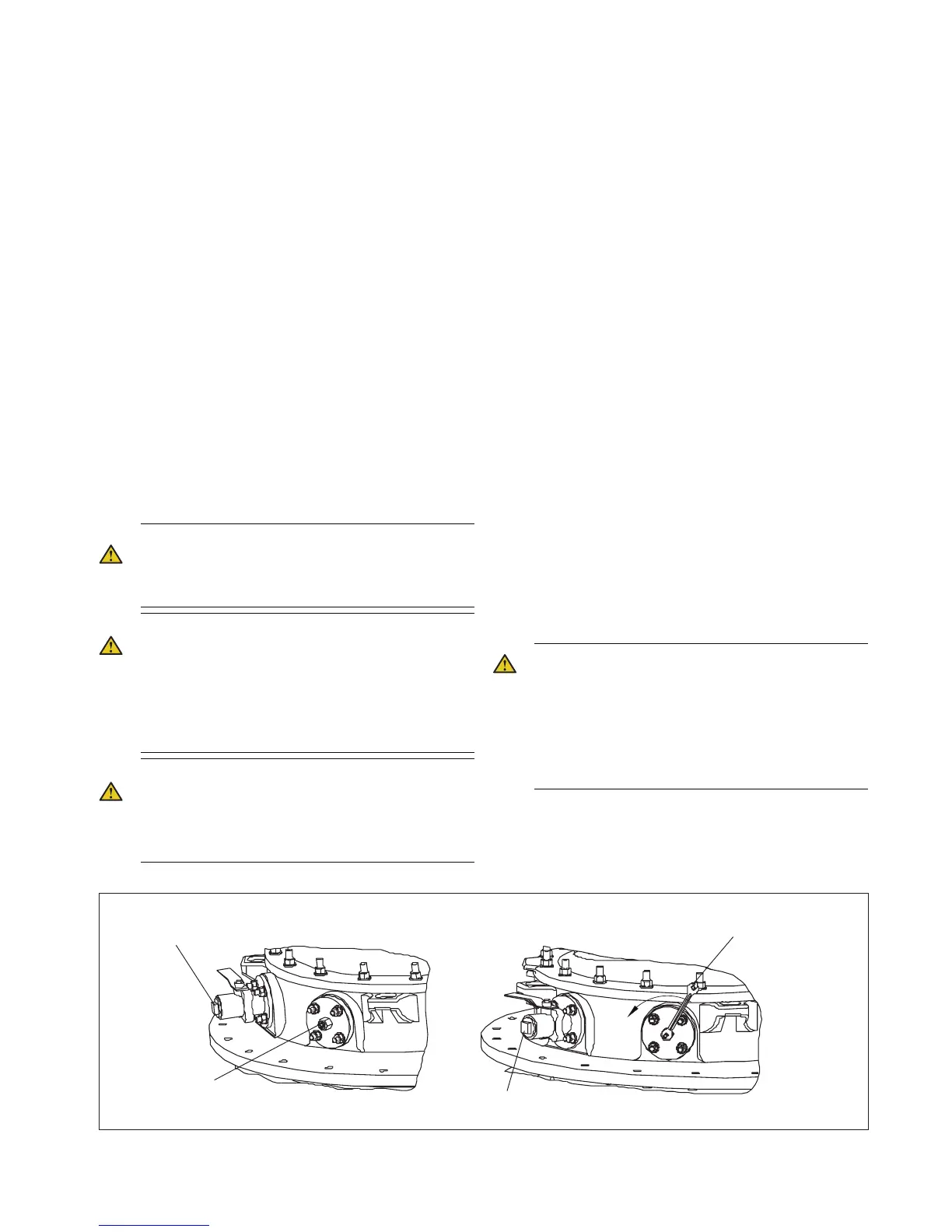

2. Connect the oil pump to the oil valve. (For connection

dimensions, see the dimension drawing for the on-load

tap-changer), see Fig. 10.

3. Open the oil valve and the air release valve.

4. Start the oil pump and drain approximately 15 litres of oil

into a clean and dry container.

5. Close the air release valve.

6. Close the oil valve and disconnect the pump.

7. Connect the output side of the pump to the oil valve.

8. Open the oil valve.

9. Open the valve in the tube to the conservator!

10. Pump the earlier drained 15 litres of oil back into the

diverter switch housing.

11. Close the oil valve and disconnect the pump.

12. The level in the oil conservator and the gas cushion are

now restored.

If the on-load tap-changer consists of more than one unit,

proceed with the other one until the last one has been

restored.

CAUTION

Avoid to do the restoring in damp weather since

moisture will get into the diverter switch housing. If

the restoring has to be done in such weather, the

incoming air has to be dehydrated and the drained oil

protected from water.

Open

Air release valve

Oil valve

Oil valve

Open end wrench

key width 6 mm

Fig. 10. Air release valve (position may be on another vertical flange).

Loading...

Loading...