Publication 20D-IN027A-EN-P

2

Before proceeding, ensure that all power to the drive has been removed.

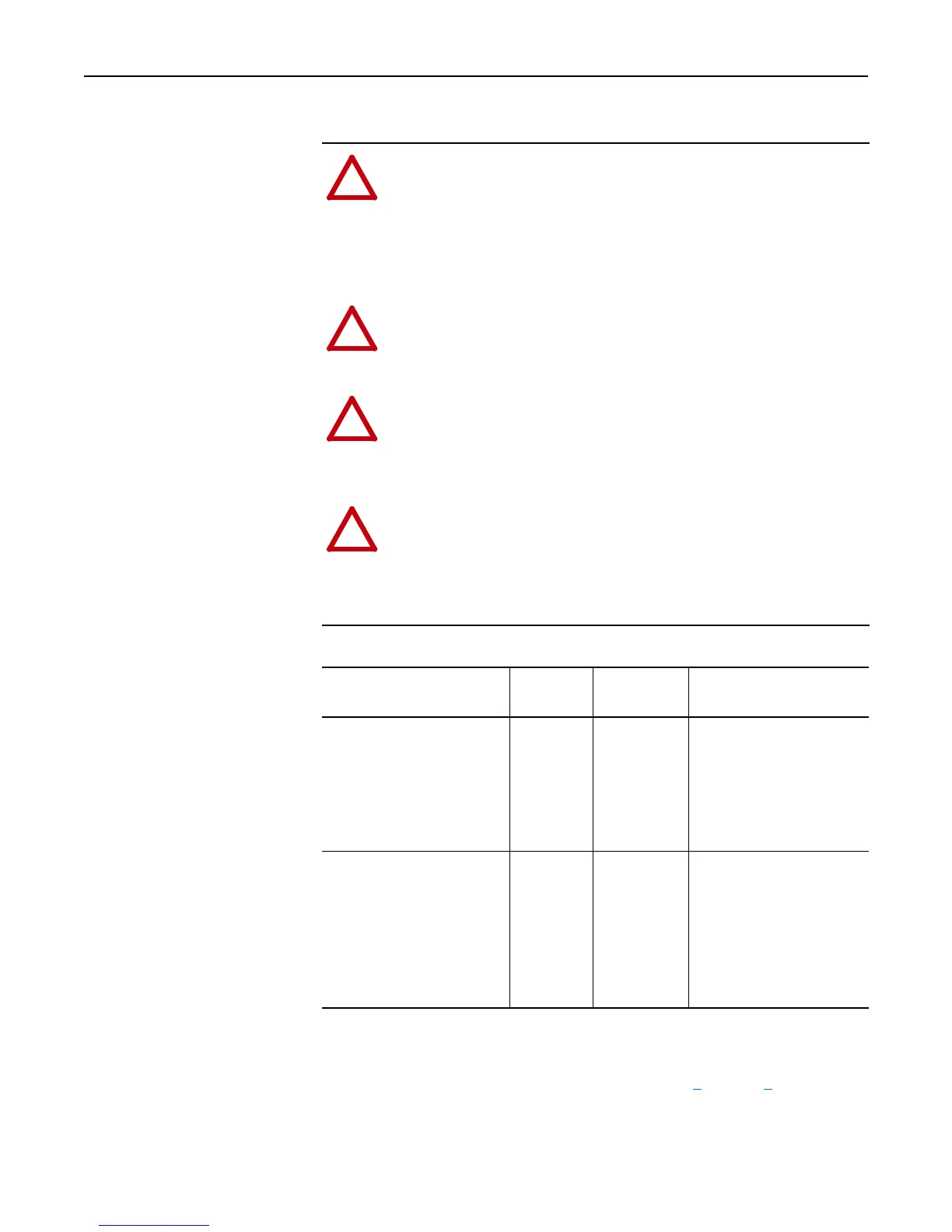

Table A Recommended Power Jumper Configurations

To connect or disconnect these devices, refer to pages 4 through 7.

!

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, Guarding Against

Electrostatic Damage or any other applicable ESD protection guide.

!

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should perform

maintenance/repair of the system. Failure to comply may result in

personal injury and/or equipment damage.

!

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing any

work on the drive. Measure the DC bus voltage at the +DC & –DC

terminals of the Power Terminal Block (refer to the User Manual for

location). The voltage must be zero.

!

ATTENTION: The following information is merely a guide for

proper installation. Rockwell Automation cannot assume

responsibility for the compliance or the noncompliance to any code,

national, local or otherwise for the proper installation of this drive or

associated equipment. A hazard of personal injury and/or equipment

damage exists if codes are ignored during installation.

Power Source Type

(1)

(1)

It is highly recommended to accurately determine the power source type and then configure appropriately.

MOV/Input

Filter Caps

(2)

(2)

When MOVs are disconnected, the power system must have its own transient protection to ensure known and

controlled voltages.

DC Bus

Common Mode

Caps

Benefits Of Correct

Configuration on Power Source

Type

Solid Ground

• AC fed, solidly grounded

• DC fed from passive rectifier

which has an AC source and

solid ground

Connected Connected • UL compliance,

• Reduced electrical noise,

• Most stable operation,

• EMC compliance,

• Reduced voltage stress on

components and motor

bearings

Non-Solid Ground

• AC fed ungrounded

• Impedance grounded

• High resistive ground

• B phase ground

• Regenerative unit such as

common DC bus supply & brake

• DC fed from an active converter

Disconnected Disconnected • Helps avoid severe equipment

damage when ground fault

occurs

Loading...

Loading...