PowerFlex 755 On-Machine Packaged Drive 3

Rockwell Automation Publication 750-PC004B-EN-P - April 2019

Packaged Drive Features

For more information on the packaged drive characteristics and catalog information, see PowerFlex 755

On-Machine Packaged Drive User Manual, publication 750-UM006

.

Dimensions

The approximate dimensions are shown in millimeters and (inches).

Software Requirements

Receive, Unpack, and Inspect the Packaged Drive

Upon delivery of the packaged drive, refer to the packing slip for sizes and shipping weights. The packing slip

lists the items that are included in the shipment. Inspect the shipment for damaged or lost items.

If the packaging appears to be damaged, take photos of the damaged shipment with the packaging, then

unpack the equipment for further inspection. Open the cover and inspect the major components for signs of

damage. Retain the original packaging for the freight inspector.

1. Inspect the shipping container for any damage that occurred during transit.

2. Remove the cover of the shipping container.

3. Remove the sides of the shipping container.

4. Remove the protective packing materials.

5. Inspect the packaged drive for any damage.

6. If enclosure appears damaged, open the front cover and inspect the major components for damage. For

instructions on how to open the front cover, see PowerFlex 755 On-Machine Packaged Drive User Manual,

publication 750-UM006

.

7. If damage to the enclosure exists:

a. Note on the delivery receipt that the equipment is damaged.

b. Contact the carrier that delivered the shipment and the authorized Rockwell Automation distributor. The

carrier may schedule a freight inspection or will waive their right to inspect. If they waive their right to

inspect, obtain the written waiver.

c. Retain all product packaging for review by the carrier.

Lift and Transport the Packaged Drive

All lifting equipment and components (hooks, bolts, lifts, slings, chains, and others) must be properly sized and

rated to safely lift and hold the weight of the packaged drive. Read these precautions before attempting to lift a

packaged drive.

IMPORTANT For proper heat dissipation and product operation, mount the device vertically as shown.

Network Software Version

EtherNet/IP RSLinx® Classic 2.50 or later

RSLogix 5000® 20.00 or previous

Studio 5000

Logix

Designer®

21.00…29.00 for hardware-based Safe Torque Off (20-750-S3)

30.00 or later for network-based Safe Torque Off (20-750-S3)

31.00 or later for Integrated Motion on EtherNet/IP networks

31.00 or later for Advanced Integrated Safety Functions Option Module

(20-750-S4)

Add-on Profile Download the most current version from

https://compatibility.rockwellautomation.com/Pages/home.aspx

PowerFlex 755

Firmware

13.00 or later when Safe Torque Off (20-750-S3) is used, 14.00 or later

when Integrated Safety Functions Option Module (20-750-S4) or

Integrated motion is used.

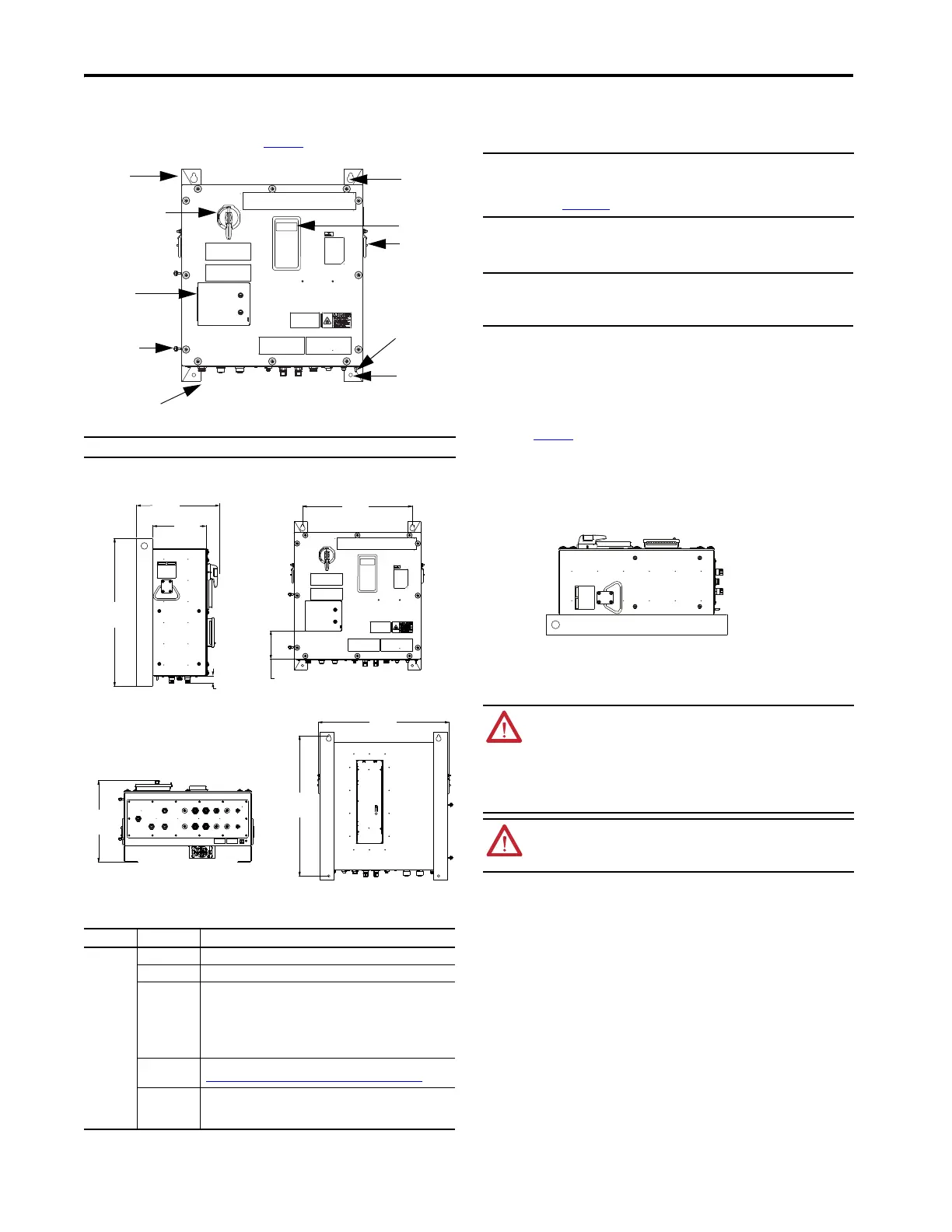

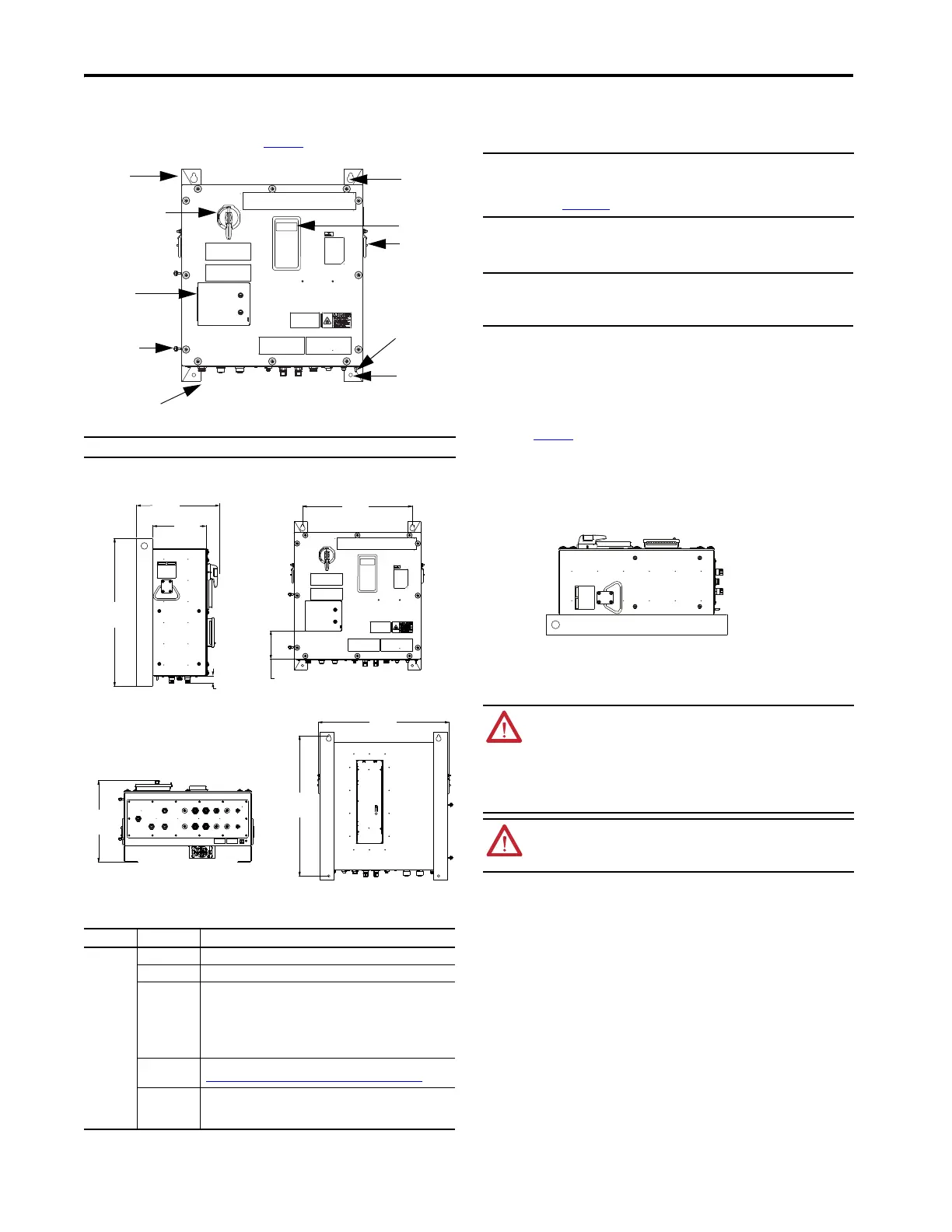

Mounting

Hole (x2)

Mounting

Hole (x2)

Hand Lifting

Handles (x2)

Hoist Lifting

Hole (x2)

Main Power

Circuit Breaker Handle

Auxiliary Circuit

Breaker Door

Connector Receptacles

HIM

Collar Stud for

Resistor Mounting

Plate (x4)

Grounding Stud

(PE Ground)

(15.43)

260.5

(10.26)

711.2

(28.00)

33.5

(1.32)

136.9

(5.39)

(20.75)

649.8

(25.58)

673.0

(26.50)

391.9

Left View

Front View

Bottom View

Back View

IMPORTANT For drives that were in storage and did not have voltage applied, maintenance of the

capacitors in the drive may be required. For drives that are stored under one year, there is

no additional maintenance required. For storage greater than one year, see Preventive

Maintenance Checklist of Industrial Control and Drive System Equipment, publication

DRIVES-TD001

for bus capacitor reforming requirements.

IMPORTANT Delivery of equipment from Rockwell Automation to the carrier is considered delivery to

the buyer. The carrier becomes liable for any damage that occurs during transit. It is the

responsibility of the buyer to notify the proper party if damage is found. The buyer can

forfeit any right to recovery for loss or damages by failing to comply with these steps.

ATTENTION: All equipment and hardware that is used to lift the packaged drive must be properly

sized and rated to safely lift and hold the weight of the packaged drive. To guard against possible

personal injury or equipment damage:

• Inspect all hardware for proper attachment before a packaged drive is lifted.

• Do not allow any part of the packaged drive or lift equipment to contact electrically charged

conductors or components.

• Do not subject the packaged drive to high rates of acceleration or deceleration during a lift or

transportation.

• Do not allow personnel or their limbs directly beneath the packaged drive during a lift.

ATTENTION: When approaching the full upright (vertical) position, the weight can shift and

cause the packaged drive to swing unexpectedly. Control the movement of the packaged drive as

it is lifted from the shipping container. Failure to comply can result in personal injury or

equipment damage.

Loading...

Loading...