2 PowerFlex 755 On-Machine Packaged Drive

Rockwell Automation Publication 750-PC004B-EN-P - April 2019

Personal Safety and Precautions

1. From user-supplied 400/480V AC, 3-phase, 50/60-Hz delta-Wye connected power distribution with solidly grounded neutral.

2. If the user-supplied input power distribution exceeds 20 times the drive rating kVA, additional impedance must be supplied in

the form of an input line reactor or isolation transformer.

Avoid Electrostatic Discharge

Electrical Safety Considerations

Environment and Enclosure

Enclosure Specifications

This section lists general specifications for the enclosure. Specifications for the components in the On-Machine

Packaged Drive are in their respective publications, see Additional Resources

.

IMPORTANT If your On-Machine Packaged Drive includes the Safe Torque Off (20-750-S3) or

Integrated Safety Functions (20-750-S4) option module, see the respective user manual,

listed in the Additional Resources

table, before operating your drive in a safety system.

ATTENTION: This unit has remote sources of power. Disconnect all power sources before the cover

is removed. Failure to comply could result in death or serious injury.

ATTENTION: Do not attempt to service internal components when the unit is energized.

Complete lock out / tag out procedures for all input power sources. Then, remove input power

(L123 and 24V DC control power) from terminals CP and CPBR (if used) before cover removal and

inspection. Failure to comply can result in death or serious injury.

ATTENTION: The 24V DC control power source can be used to aid in troubleshooting, but you

must follow local codes while the control power is energized, input power L123 is not energized,

and the cover is removed. Control power is connected to receptacles CP (24V DC auxiliary power)

and CPBR (24V DC brake options: B2and B3). Failure to comply can result in serious injury or

death.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus capacitors has

entirely discharged before servicing.

ATTENTION: The packaged drive contains high-voltage capacitors that take time to discharge

after removal of the main power supply. Before working on the drive, isolate the main power

supply from the line input (L123). Wait 3 minutes for the capacitors to discharge to minimal

voltage levels. Failure to do so can result in personal injury or death.

ATTENTION:

• Installation, adjustments, adding into service, use, assembly, disassembly, and maintenance

shall be performed by suitably trained personnel in accordance with the applicable code of

practice.

• If this equipment is used in a manner not specified by the manufacturer, the protection that is

provided by the equipment, may be impaired.

WARNING: Circumstances that can cause an explosion may exist, which may lead to personal

injury or death, property damage, or economic loss. Tripping of the instantaneous-trip circuit

breaker is an indication that a fault current has been interrupted. Current-carrying components of

a magnetic motor controller should be examined and replaced if they are damaged to reduce the

risk of fire or electrical shock.

ATTENTION: This publication is intended for qualified service personnel responsible for installing

and servicing these devices. The user must have previous experience and a basic understanding of

electrical terminology, configuration procedures, required equipment, and safety precautions.

ATTENTION: The National Electrical Code (NEC), NFPA79, and any other governing regional or

local code overrules the information in this publication. Rockwell Automation cannot assume

responsibility for the compliance or proper installation of the On-Machine Packaged Drive or

associated equipment. A hazard of personal injury and/or equipment damage exists if codes are

ignored during installation.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when you install, test, service, or repair this assembly.

Component damage can result if ESD control procedures are not followed. If you are not familiar

with static control procedures, see an applicable ESD protection handbook.

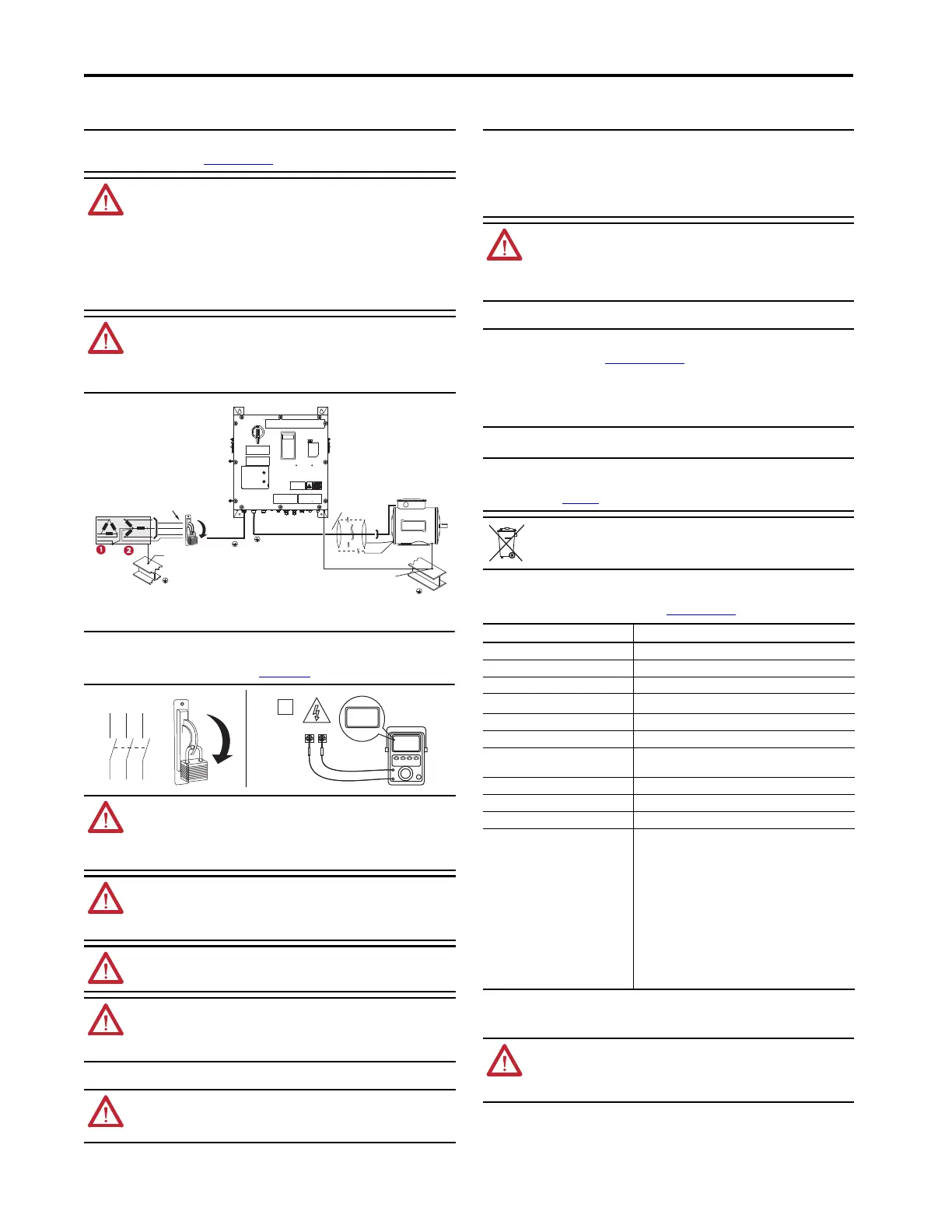

U (T1)

V (T2)

W (T3)

SHLD

Exposed Structure

and/or Building Steel

Shielded

Motor Cable

M35

R (L1)

S (L2)

T (L3)

Maximum

65,000 A SCCR

Exposed Structure

and/or Building Steel

DC+ DC-

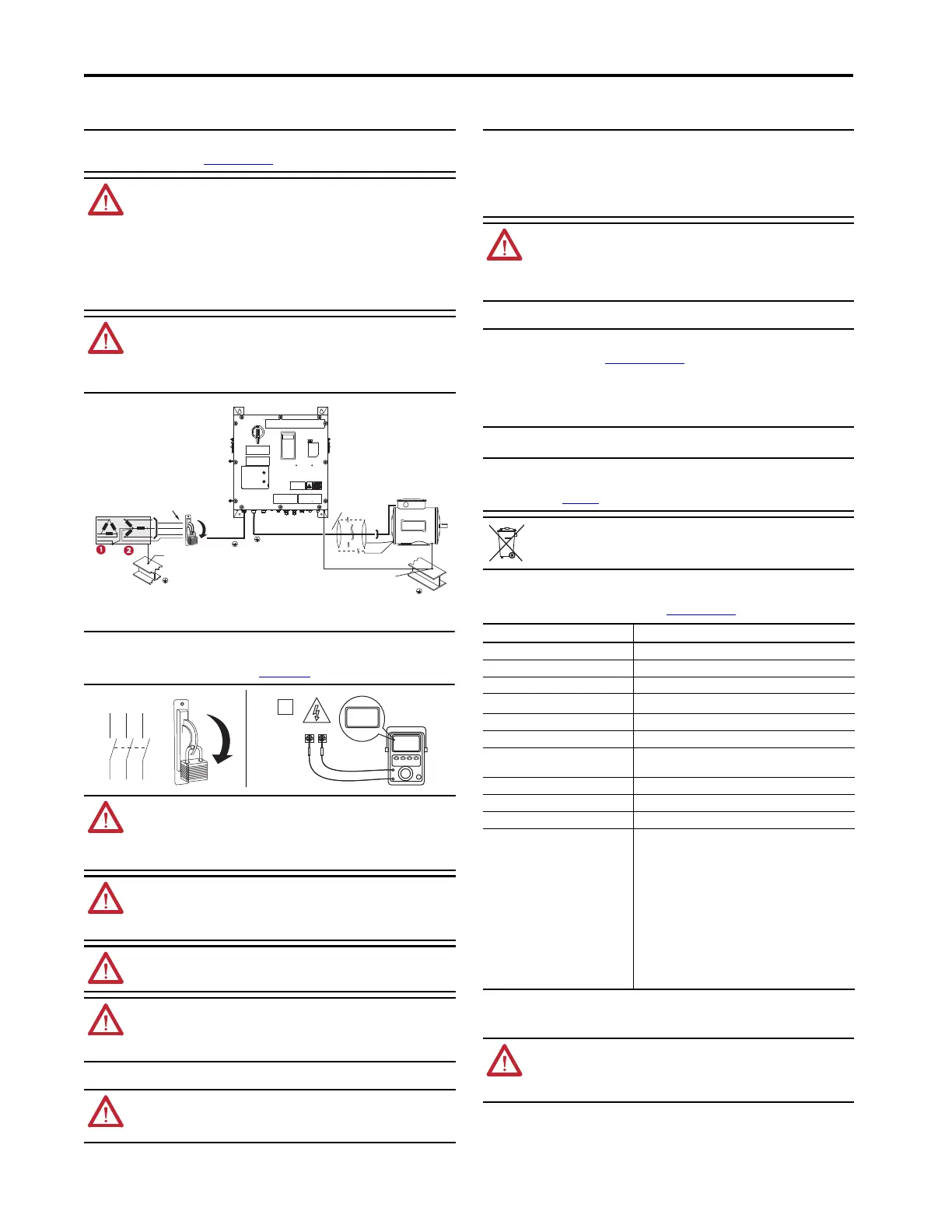

IMPORTANT This lock out / tag out is only for upstream power. During initial installation, the

On-Machine Packaged Drive does not have power. The breakers should be in the OFF

position when the unit arrives. Verify that all breakers are off before installation is started.

For more information, see the Circuit Breakers

section.

L1 L2 L3

O

I

IMPORTANT To comply with the CE Low Voltage Directive (LVD), all connections to this equipment

must be powered from a source compliant with the following:

• Safety extra low voltage (SELV) Supply

• Protected extra low voltage (PELV) Supply

To comply with UL/C-UL requirements, this equipment must be powered from a source

compliant with the following:

• IEC 60950-1 Ed. 2.1, Clause 2.2 - SELV Circuits

ATTENTION: To avoid electrical shock, open the appropriate upstream protection (disconnect

switch or branch circuit protection) before connecting and disconnecting cables.

ATTENTION: Risk of shock exists. Unused receptacles should be capped, the environmental rating

may not be maintained when receptacles remain uncapped.

ATTENTION: Do not operate controls or open covers without appropriate personal protective

equipment. Failure to comply can result in serious injury or death.

IMPORTANT This equipment is supplied as enclosed equipment. It should not require an additional

system enclosure when used in locations consistent with the enclosure type ratings

stated in the Enclosure Specifications

section of this publication. Subsequent sections of

this publication may contain additional information regarding specific enclosure type

ratings, beyond what this product provides, that are required to comply with certain

product safety certifications.

See also the following: NEMA 250 and IEC 60529, as applicable, for explanations of the

degrees of protection provided by enclosures

IMPORTANT This equipment is not intended for use in residential environments and may not provide

adequate protection to radio communication services in such environments.

IMPORTANT This equipment is intended for use in overvoltage Category III applications (as defined in

IEC 60664-1), at altitudes up to 2000 m (6562 ft) at the default carrier frequency without

derating. See PowerFlex 755 On-Machine Packaged Drive Technical Data, publication

750-TD003

for altitude and derating information.

At the End of Life, this equipment should be collected separately from any unsorted municipal

waste.

Condition Requirement

Ambient Operating Temperature 0 °C…40 °C (32 °F…104 °F)

Storage Temperature -20°C…70 °C (-4°F…158 °F)

Relative Humidity 5…95% (non-condensing)

Cabinet Rating

(1)

(1) Enclosure provides protection from dust and falling debris.

UL Type 12 / NEMA 12 / IP66 (indoor use only)

Enclosure Dimensions (H x W x D) 609.6 mm x 609.6 mm x 274.4 mm (24 in x 24 in x 11 in)

Product Dimensions Installed (H x W x D) 711.2 mm x 649.8 mm x 391.9 mm (28 in x 25.58 in x 15.43 in)

Packaging Dimensions (H x W x D)

with product inside

475 mm x 800 mm x 800 mm (18.69 in x 31.5 in x 31.5 in)

Weight 47.62 kg (105 lbs (apx.))

Weight with packaging 63.95 kg (141 lbs (apx.))

Short-circuit current rating Maximum short circuit rating 65,000 A RMS symmetrical

Incoming Power and

Power Ratings and Voltages

(2)

(2) All ratings to support continuous duty. There is no de-rate for duty cycle variations. All ratings are for normal duty except for

the variation that has 14 A Heavy-Duty rating.

400V AC, 3 HP, 50-Hz ratings:

• 8.7 A, 4 kW, Normal Duty

• 11.5 A, 5.5 kW, Normal Duty

• 15.4 A, 7.5 kW, Normal Duty

• 22 A, 11 kW, Normal Duty

480V AC, 3 PH, 60-Hz ratings:

•8 A, 5 HP, Normal Duty

• 11 A, 7.5 HP, Normal Duty

• 14 A, 10 HP, Normal Duty

• 22 A, 15 HP, Normal Duty

• 14 A, 15 HP, Heavy Duty (only when Motor Type = M2)

WARNING: Circumstances that can cause an explosion may exist, which may lead to personal

injury or death, property damage, or economic loss. Incoming power requirements must be a

delta-Wye solid ground neutral to maintain the CE/UL certification. If the user supplied input

power distribution exceeds 20 times the drive rating kVa, additional impedance must be supplied

in the form of an input line reactor or isolation transformer.

Loading...

Loading...