Copyright © 2004 General Motors Corp. 1–5

GENERAL INFORMATION

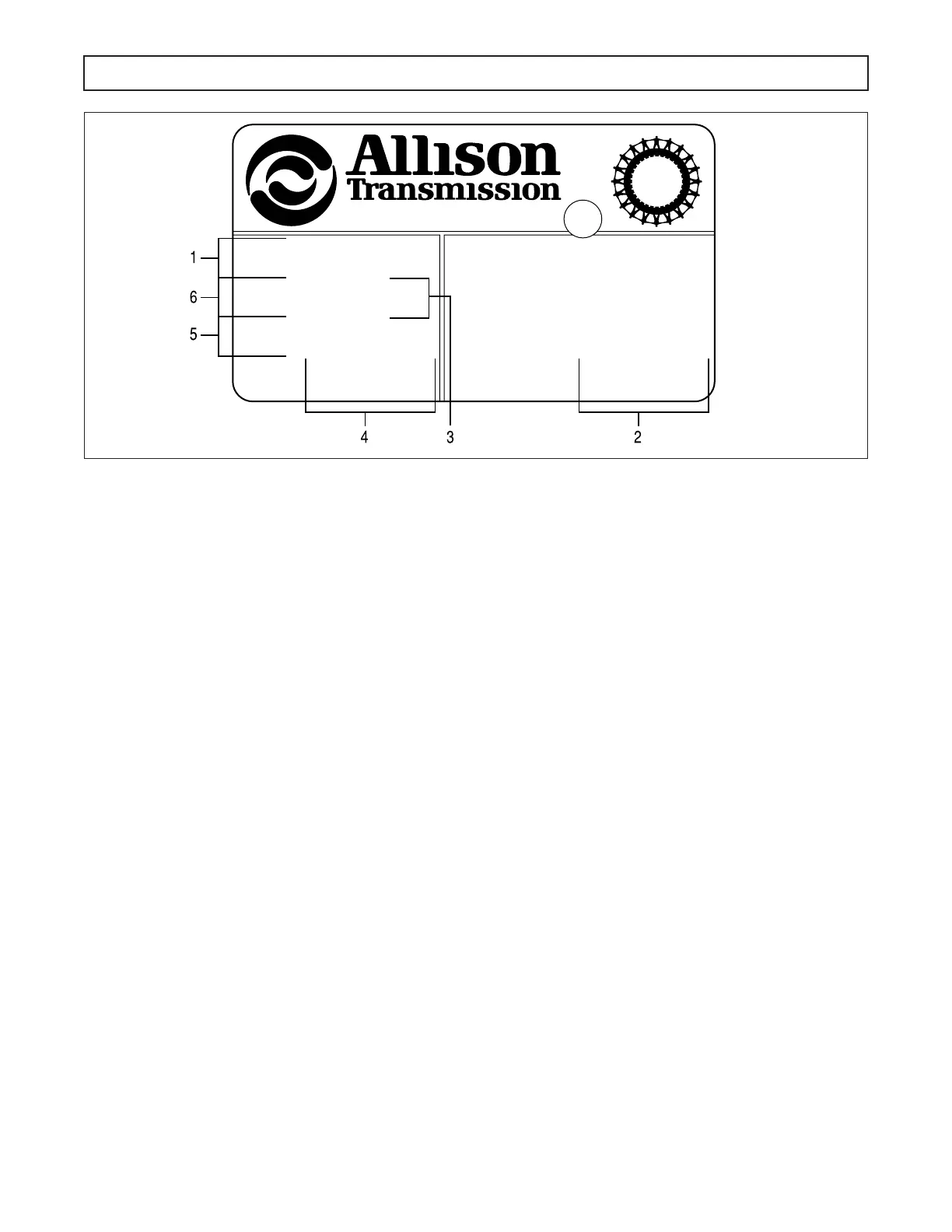

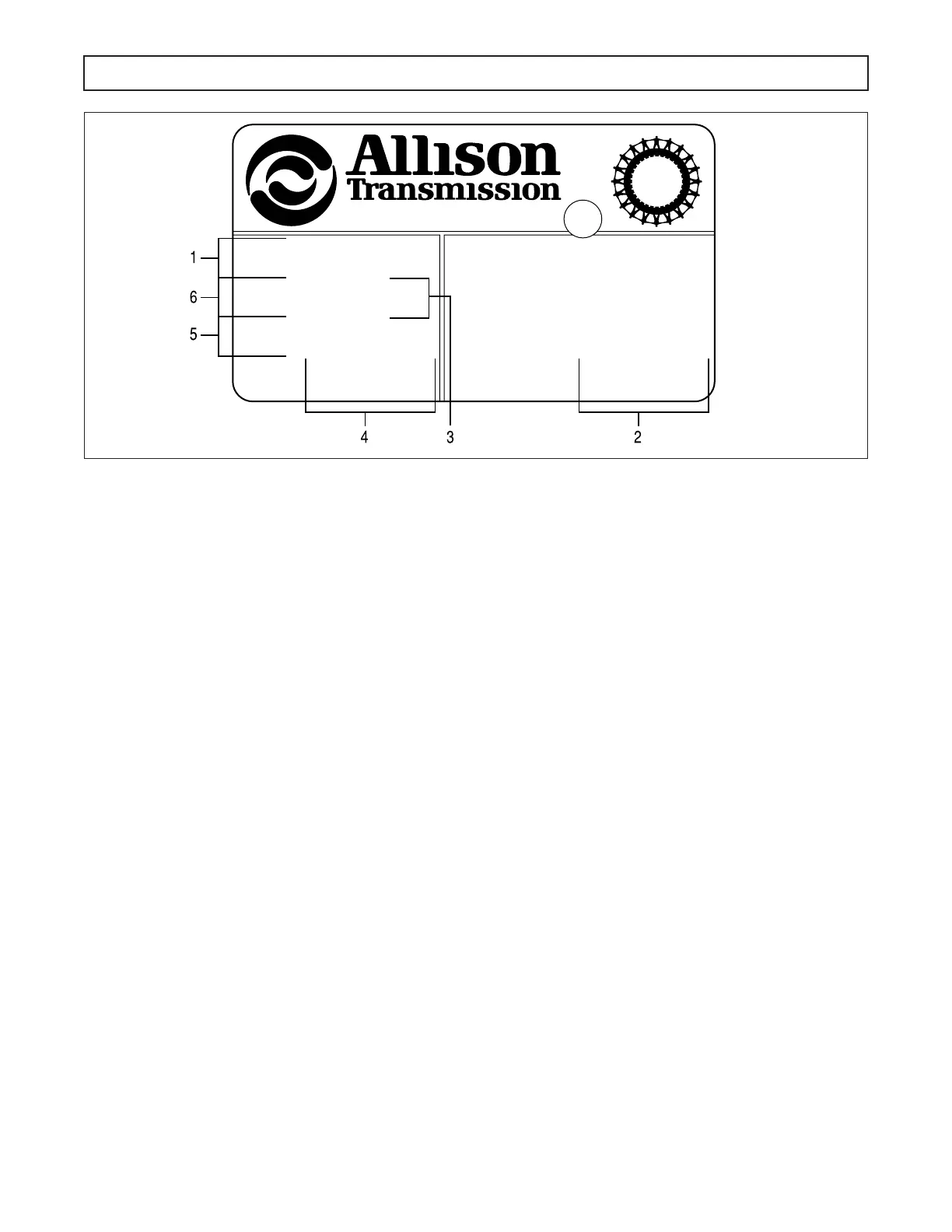

Legend

Figure 1–5. 1000 and 2000 Product Families Transmission Nameplate Components (Before March, 2000)

(1) Model (Series) (4) Engineering Feature Configuration Number

(2) Engineering Group Number (5) Serial Number

(3) Transmission Identification Number (6) Date of Manufacture

E

C

A

P

S

O

R

E

A

E

L

I

B

O

M

O

T

U

A

D

E

T

I

N

U

A

C

I

R

E

M

A

F

O

S

R

E

K

R

O

W

T

N

E

M

E

L

P

M

I

L

A

R

U

T

L

U

C

I

R

G

A

D

N

A

UAW

933

DIVISION OF GENERAL MOTORS CORP.

DIVISION OF GENERAL MOTORS CORP.

INDIANAPOLIS, INDIANA

SERIAL NO.

MODEL

EFCN

DATE TID

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XX–XXXX

XXXXXXX

XXXXXXXXXX

XXXXX XX

1 000SERI ES

1–4. GENERAL DESCRIPTION

a. Transmission Design Features. Allison 1000 and

2000 Product Families (Figures 1–1 and 1–2) are

torque-converter driven, electronically controlled,

fully automatic transmission systems. The 1000 and

2000 Product Families transmissions have up to five

forward speeds, neutral, and reverse. The fifth range

has an overdrive gear ratio. The 1000 and 2000 Product

Families incorporate a variety of standard and optional

design features.

1. Transmission-to-Engine Coupling. The con-

verter housings of 1000 and 2000 Product Fami-

lies transmissions mate directly to SAE No. 2

or No. 3 flywheel housings or to the engine

block in some cases. Flexplate drive is used for

engine-to-transmission torque transfer.

2. Torque Converter. Several torque converters are

available to match the transmissions to a wide

variety of diesel and gasoline engines. The

torque converter is a single-stage, polyphase,

three-element unit, consisting of a pump, sta-

tor, and turbine. At lower output speeds, the

torque converter multiplies torque and provides

a fluid coupling to the engine. At higher speeds,

the torque converter clutch (TCC) is automati-

cally engaged to provide direct drive from the

engine to the transmission. Hydraulic fluid for

converter charging pressure comes from the

sump and is supplied by the input pump. The

torque converter clutch is applied or released by

changing direction of fluid in the torque con-

verter. An integral converter damper minimizes

the need for additional engine vibration control.

3. Planetary Gearing. The planetary gear train in-

cludes three constant-mesh, helical gear plane-

tary sets. By the engagement of clutches in

various combinations, the planetary sets act

singly or together to provide five forward

ranges, neutral, and reverse.

4. Clutches. Five clutches (two rotating and three

stationary) direct the flow of torque through

the transmission. All range clutches are hy-

draulically-actuated and spring-released, with

automatic wear compensation. Clutches are

cooled by the transmission fluid. The transmis-

sion electronic control module signals solenoid

valves to apply and release clutches based on

speed and power combinations and the range

selected by the operator.

Loading...

Loading...