FOR MODELS: JGW, JGR AND JGJ SECTION 4 - LUBRICATION AND VENTING

PAGE 4 - 20 1/01

Setting and Maintaining Balance Valves

Balance valves cannot be set prior to operating the unit. Ensure that all fittings are tight and

any known leaks have been fixed.

Purge the force feed lube system with a high-pressure hand pump, using the same injection

oil that is used in service, to remove any trapped air or gas in the system. DO NOT USE

ANY OTHER FLUIDS FOR PURGING!

Start up the compressor and bring up to normal operating pressure. After the operating pres-

sures have stabilized, adjust the cap on the top of the balance valve if necessary. Loosen

the locking nut on the top of the balance valve directly under the cap. Turn the cap clockwise

to increase the pressure and counter clockwise to decrease the pressure. Retighten the

locking nut against the cap.

Set the balance valves and maintain at approximately same pressure on each pressure

gauge in the injection lines of the pump system affected. A system should be set and main-

tained within 500 psi (3400 kPa) total or less. The closer the individual line pressures are

maintained, the more reliable the system will become.

Once the balance valves have been set, they should be checked 4 to 6 hours later to ensure

the pressures have not changed and caused another imbalance. If readjustment is neces-

sary the gauges should be checked again in 4 to 6 hours. If a pressure gauge in a line with a

balance valve is reading more than 500 psi (3400 kPa) higher than the others, try to reduce

the pressure on that particular injection line. If reducing the balancing pressure on the bal-

ance valve does not drop the pressure, then the other balance valves will need to be

adjusted to match the highest pressure.

To set balance valves equipped with a distribution block inlet gauge only:

1. Start up the compressor and bring up to normal operating pressure. After the

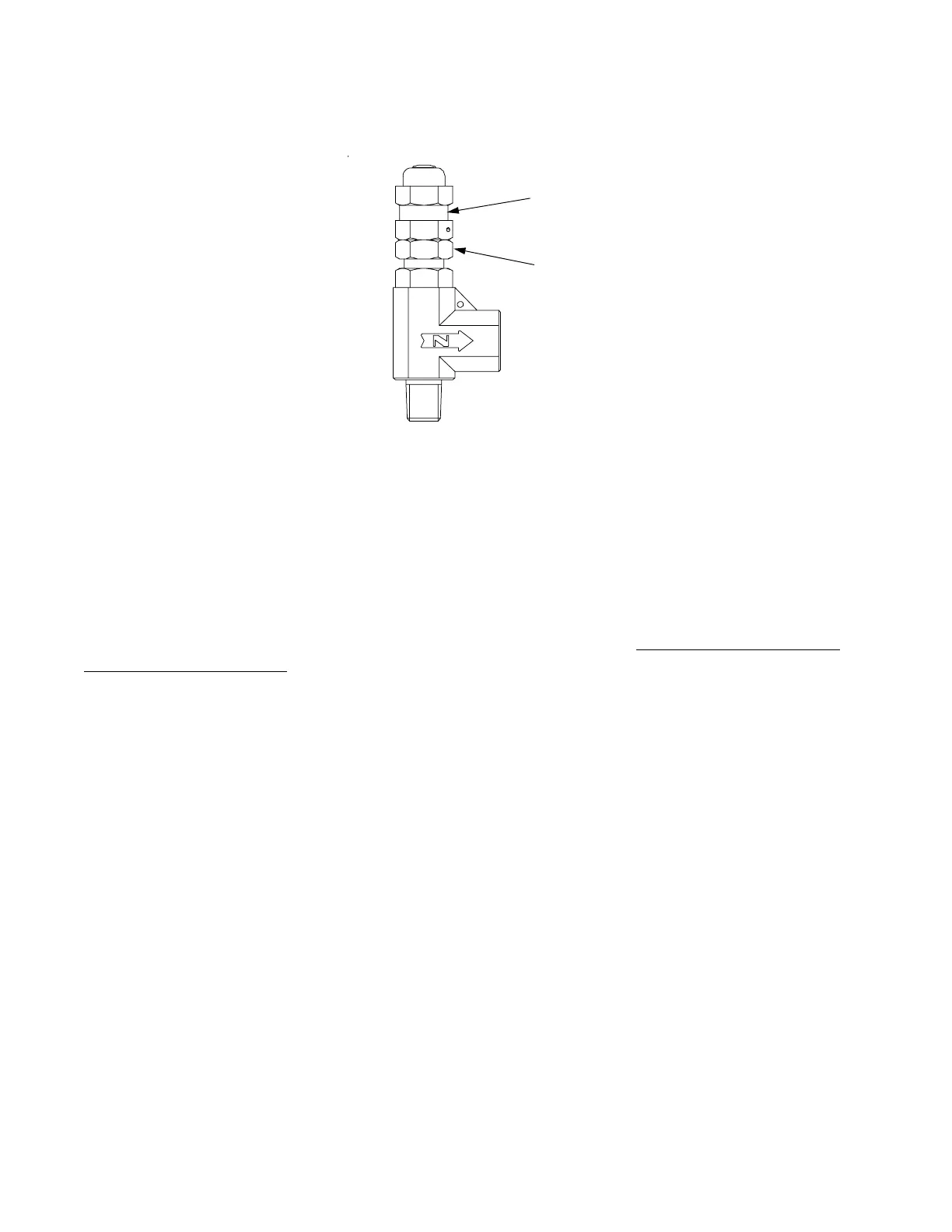

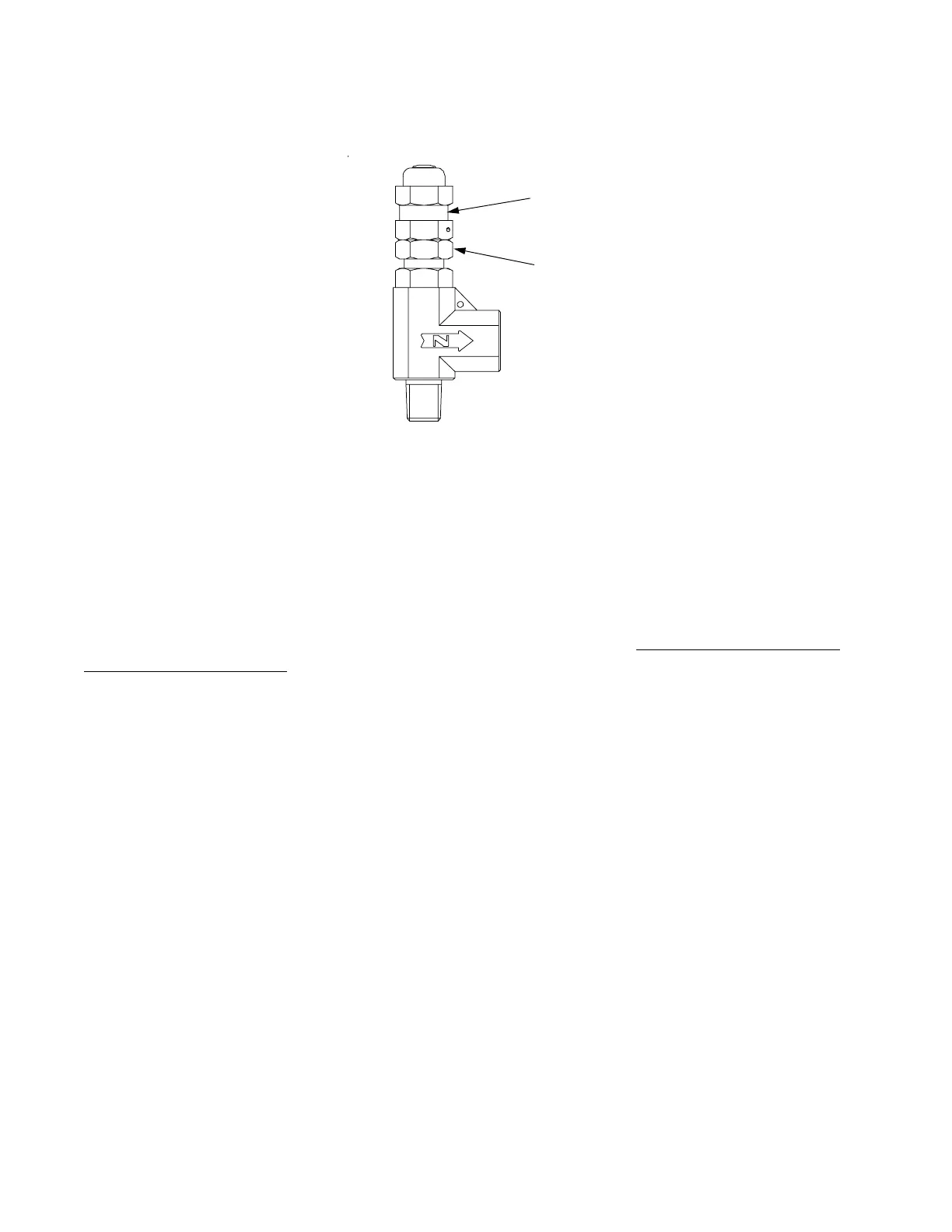

FIGURE 4-9: FORCE FEED BALANCE VALVE

Valve Cap

Lock Nut

Loading...

Loading...