FOR MODELS: JGW, JGR AND JGJ SECTION 5 - MAINTENANCE

1/01 PAGE 5 - 9

7. Before removing the crankshaft from the crankcase, wooden saddles or a

notched wooden crate with sides high enough to prevent the webs or oil slinger

from touching bottom should be prepared in order to store the crankshaft during

maintenance - even though it may be out for only a short time. In addition, the

crankshaft should be adequately protected from above so that dropped tools or

equipment cannot mar the surface of pins and journals.

8. Turn the crankshaft so that sling lifting point(s) are above the center of gravity of

the shaft, so that it does not want to rotate when lifted. Lift straight up with the

ends of the crankshaft parallel to the frame. Two persons will be needed to

safely remove the crankshaft as well as a crane or lift due to the weight of the

crankshaft (see Table 5-1). Appropriately sized nylon slings should be used dur-

ing this operation to avoid marring of the running surface of the crankshaft.

Great care must be taken during this operation since the shaft could bind and

become damaged.

NOTE: THE LOWER HALF BEARING SHELLS SOMETIMES HAVE A TENDENCY TO

STICK TO THE SHAFT JOURNALS BECAUSE OF THE CLOSE FITTING OILY

SURFACES OF THE TWO PARTS. THEREFORE, WHEN THE SHAFT HAS

BEEN LIFTED CLEAR OF THE SADDLES, APPROXIMATELY 1/4 inches OR 6

mm, CHECK TO MAKE SURE THAT THE LOWER HALF BEARING SHELLS

HAVE NOT COME OUT WITH THE SHAFT. IF SO, THE BEARING SHELLS

SHOULD BE TAPPED BACK ONTO THE SADDLES BEFORE LIFTING THE

SHAFT ANY FURTHER.

9. While one person operates the crane, raising it very slowly, the second person

must grasp the crankshaft at the drive end with one hand on the counterweight

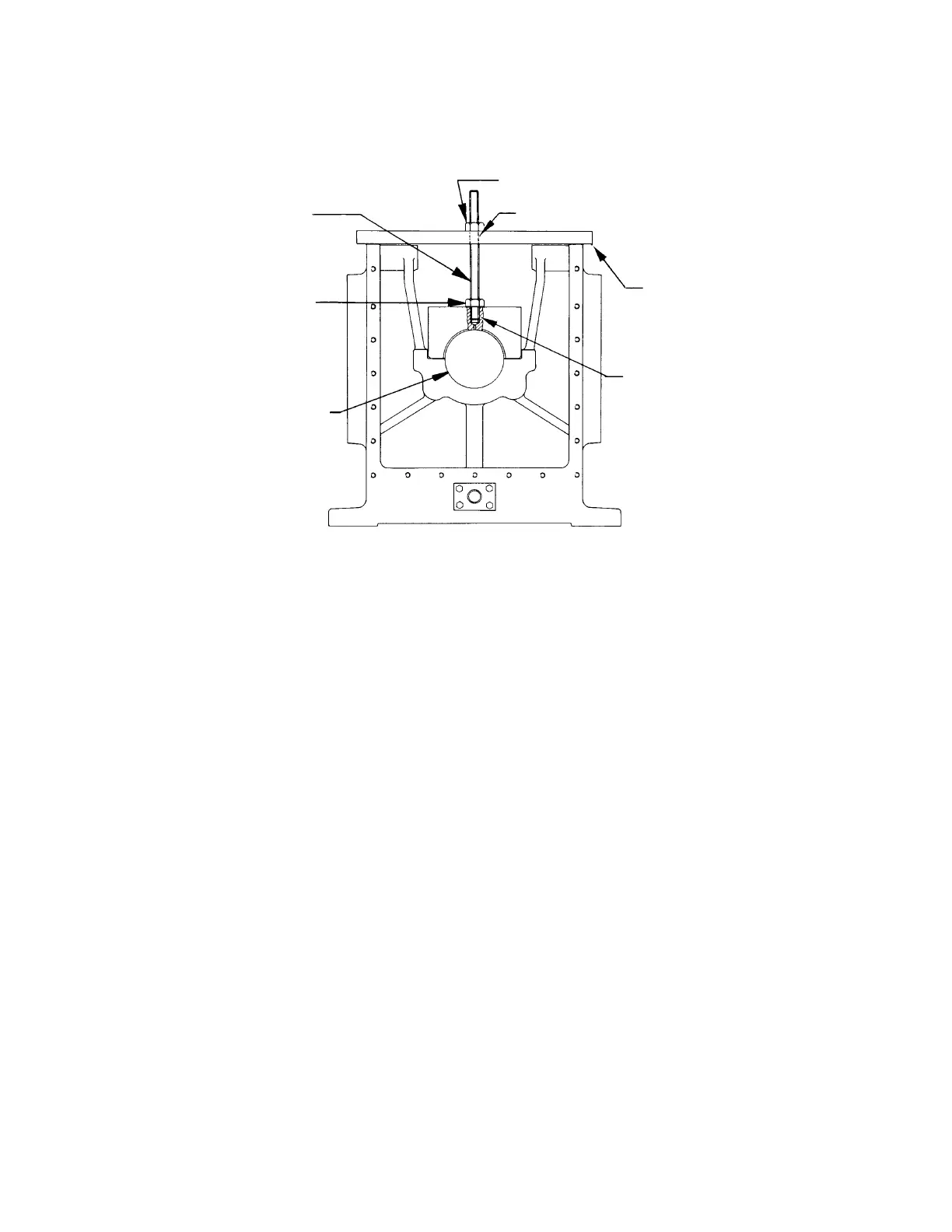

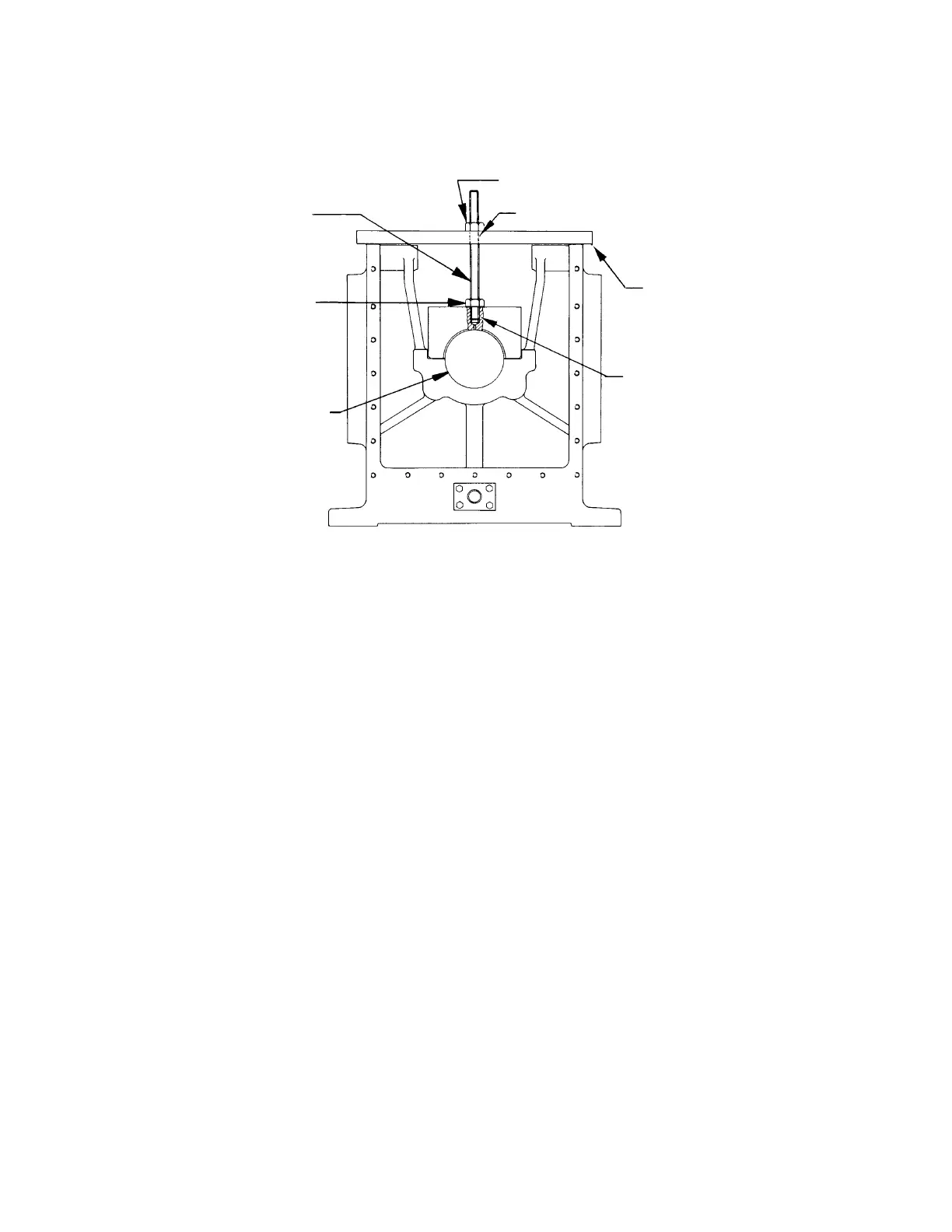

FIGURE 5-5: BEARING CAP PULLER

16” (406 mm) Long

Steel Bar

5/8-11 UNC (Jack Nut) Turn this Nut

to Jack Bearing Cap straight up.

7” (178 mm) Long

5/8-11 UNC

Threaded Rod

5/8-11 UNC

Lock Nut

Crankshaft

5/8-11 UNC

Puller Hole

Drill an 11/16” (17.5 mm) Hole

Loading...

Loading...