IRTT-B User Guide

6 (8) 9836 4436 01 Revision 2010-01

SCHEDULED MAINTENANCE

There are no critical maintenance activities required by the transducer.

Annual calibration is still required.

TROUBLESHOOTING GUIDE

Here is a quick troubleshooting guide for the IRTT-B Transducer.

If a problem appears, before taking any action (replacing parts or contacting the customer support) be sure that the transducer is being used in the

proper way and connected to a proper and working measurement unit; improper operations can cause defects or incorrect readings even if the

transducer is good.

Note: there are no spare parts available for the IRTT-B transducer.

INFORMATION ACCORDING TO WEEE DIRECTIVE

Here the instruction about how to dismiss the wasted items:

Problem Cause Solution

Shaft stiff to turn Bearing defect due to:

a) Torsional or flexural vibration

b) High axial or radial loads

c) Worn bearings

d) Bent shaft

Send unit for repair/replacement

Zero shift less than 2%

Torsional vibration

Torsional shock

The zero reading can be readjusted at the display

Zero shift between approx. 2 and 5% of

full scale

Torquemeter has been overloaded

Torsional vibration

Torsional shock

The zero reading can be readjusted once at the display

Hysteresis between clockwise and

counterclockwise torque

Torquemeter overloaded by high

alternating loads or torsional vibration

Send unit for repair/replacement

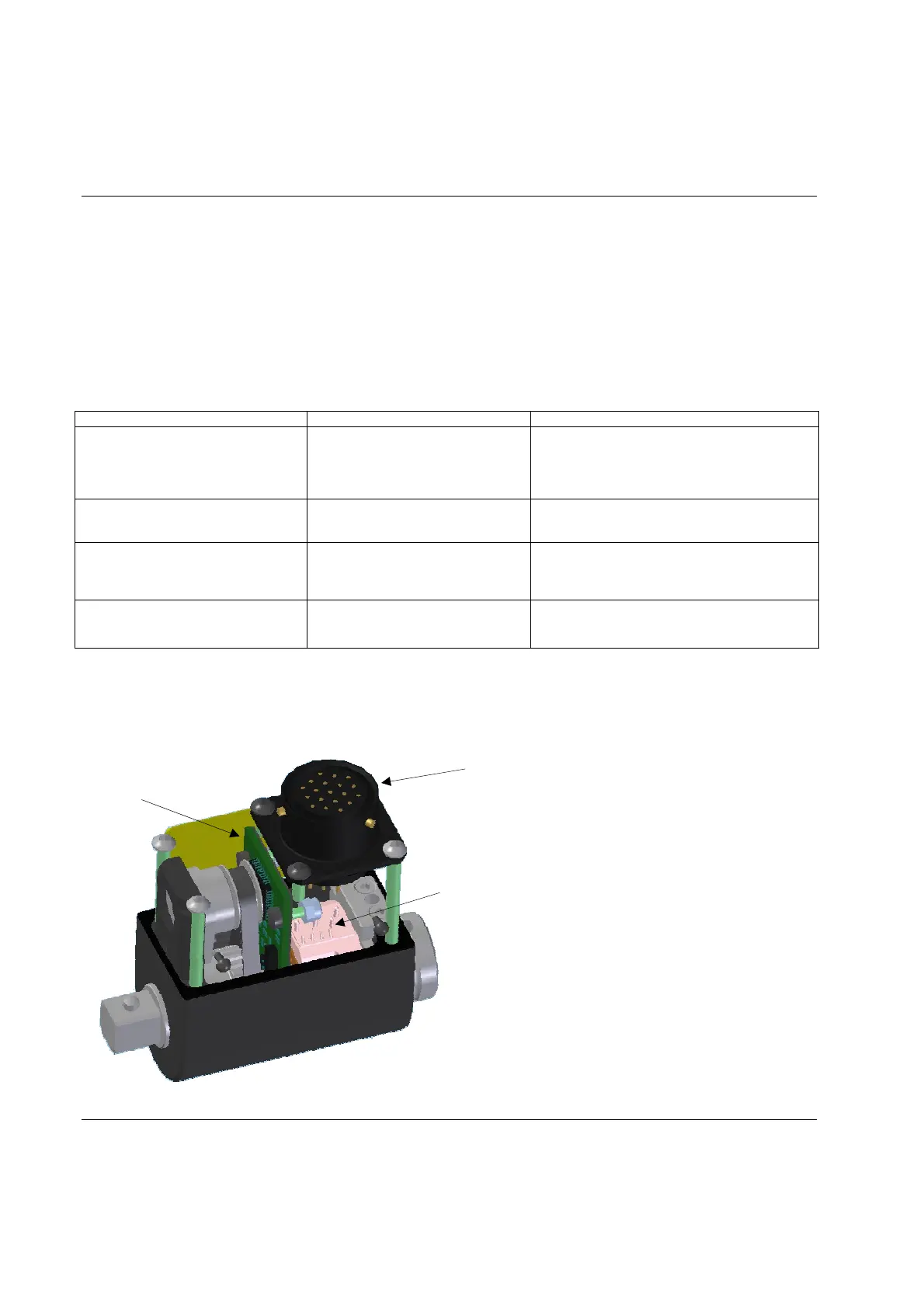

Electronic board

Connector

Brushes

1. Remove the cover

Separate the electronic parts:

2. Connector

3. Electronic board

4. Brushes

Loading...

Loading...