16

Assumption:

You want to use the green lamp on the Stacklight to signal a Job OK.

The lamp should light up at Job OK and should come off only when

you push the Stacklight button.

Solution:

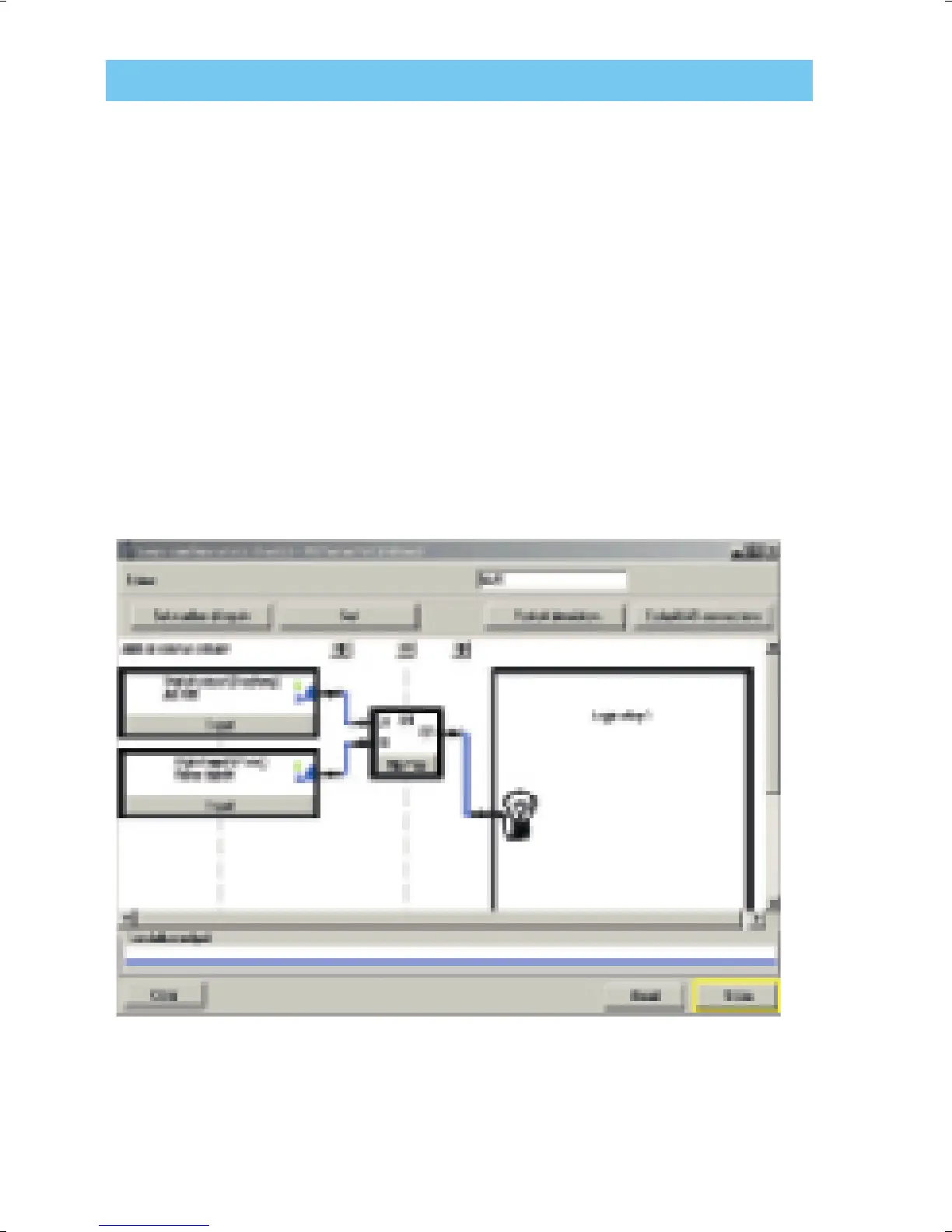

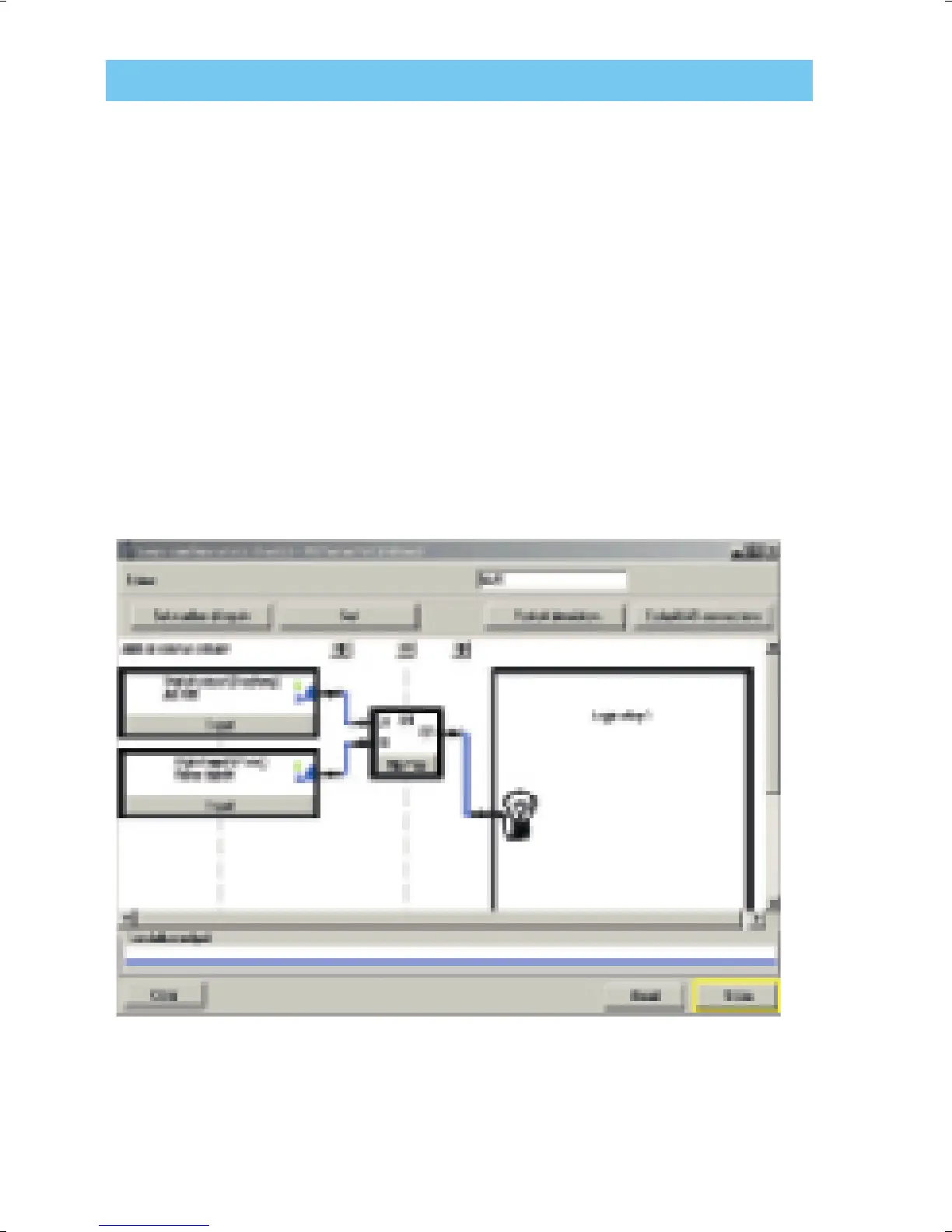

Create a Logic Confi gurator that controls the described ”process”. It

should have two Inputs – one for the Job OK signal and one for the

”button push”.

Use a Flip-fl op gate (SR type) to control the on or off of the lamp.

Let the Job OK signal be the ”S1” input. But how do we treat the

”button push” signal?

Logic Confi gurator

Loading...

Loading...