XAS136/186 Dd

22

5.2 AIR FILTER ENGINE/COMPRESSOR

5.2.1 MAIN PARTS

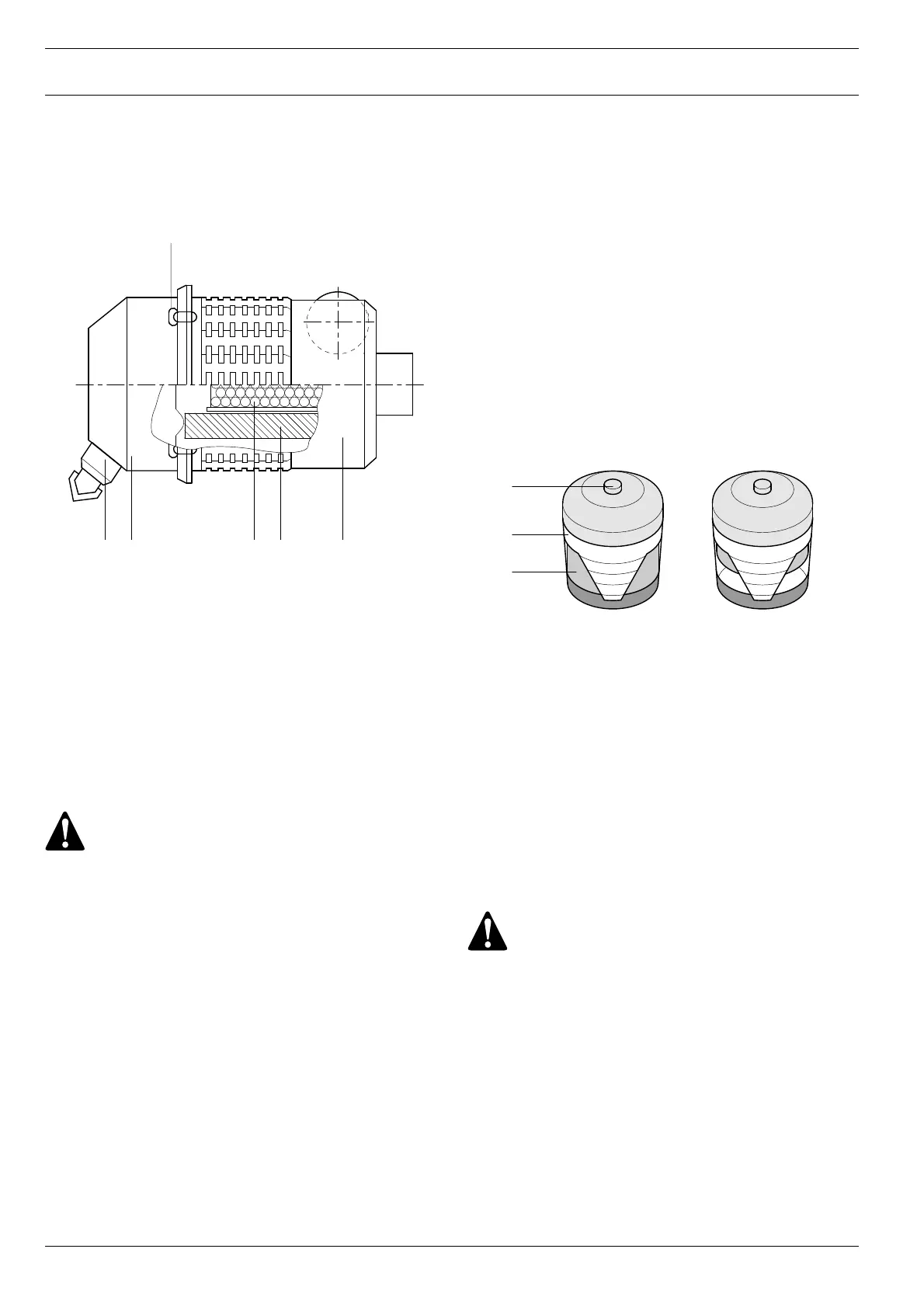

Fig. 5.2 Air filter

1 Snap clips

2 Dust trap

3 Safety cartridge (option)

4 Filter element

5 Filter housing

6 Vacuator valve

5.2.2 RECOMMENDATIONS

The Atlas Copco air filters are specially designed for the

application. The use of non-genuine air filters may lead

to severe damage of engine and/or compressor element.

Never run the compressor without air filter element.

New elements must also be inspected for tears or punctures before

installation.

Discard the element (4) when damaged.

In heavy duty applications it is recommended to install a safety

cartridge which can be ordered with

part no.: 2914 9311 00

A dirty safety cartridge (3) is an indication of a mal-functioning air

filter element. Replace the element and the safety cartridge in this

case.

The safety cartridge cannot be cleaned.

5.2.3 CLEANING THE DUST TRAP

To remove dust from the dust trap pinch the vacuator valve (6)

several times.

5.2.4 REPLACING THE AIR FILTER ELEMENT

1. Release the snap clips (1) and remove the dust trap (2).

Clean the trap.

2. Remove the element (4) from the housing (5).

3. Reassemble in reverse order of dismantling.

4. Inspect and tighten all air intake connections.

5. Reset the vacuum indicator (Fig. 5.3).

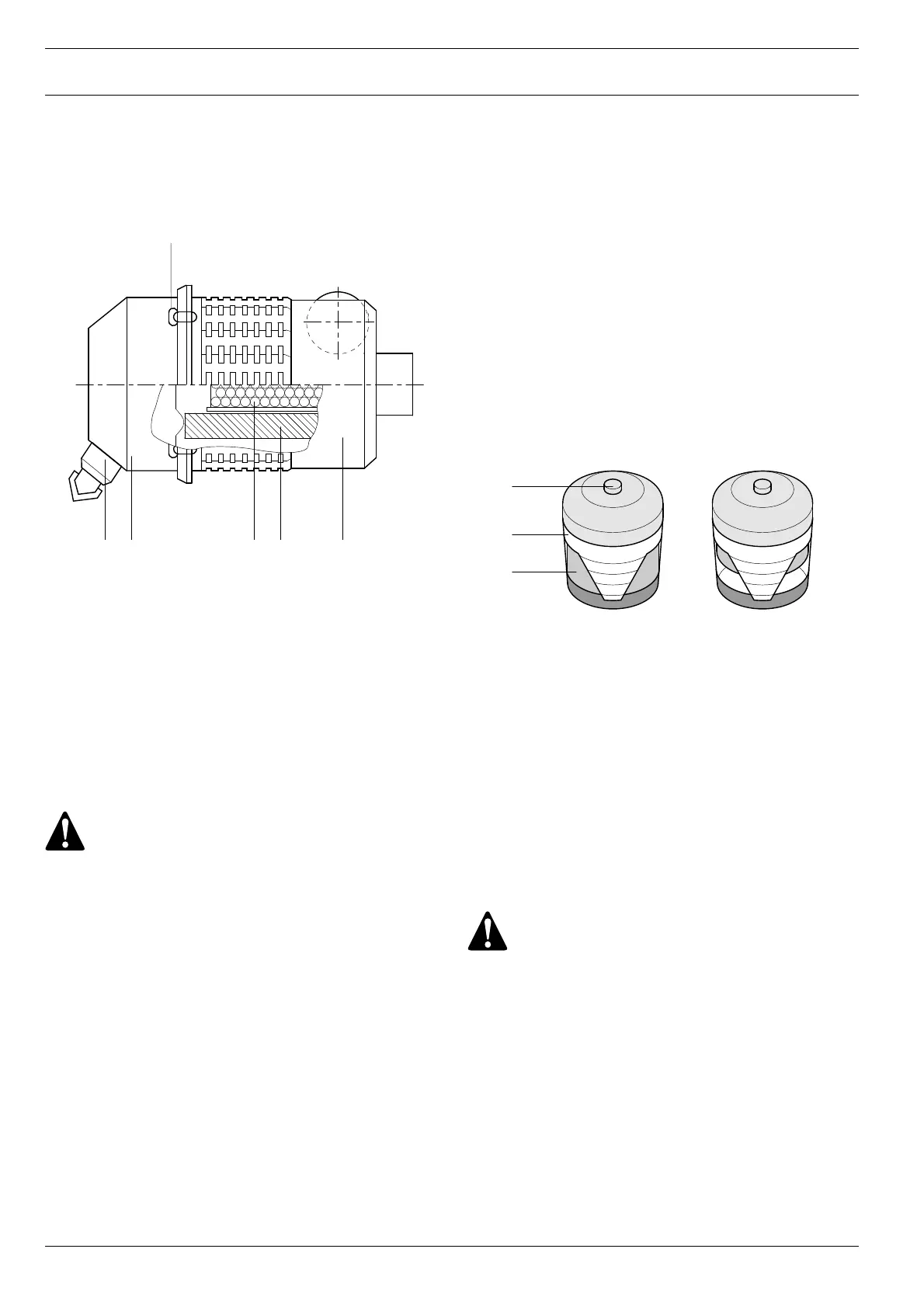

Fig. 5.3 Vacuum indicator

7 Air filter contamination indicator

8 Reset button

9 Yellow indicator

5.3 AIR RECEIVER

The air receiver is tested according to official standards. Regularly

have inspections carried out in conformity with local regulations.

5.4 SAFETY VALVE

All adjustments or repairs are to be done by an

authorized representative of the valve supplier.

Following checks must be carried out:

Ð a check of the opening of the lifting gear, twice a year.

This can be done by screwing the cap of the valve anti-clockwise.

Ð a check of the set pressure once a year according to the local

regulations. This check cannot be done on the machine and must

be carried out on a proper test bench.

Loading...

Loading...