Adaption

Power

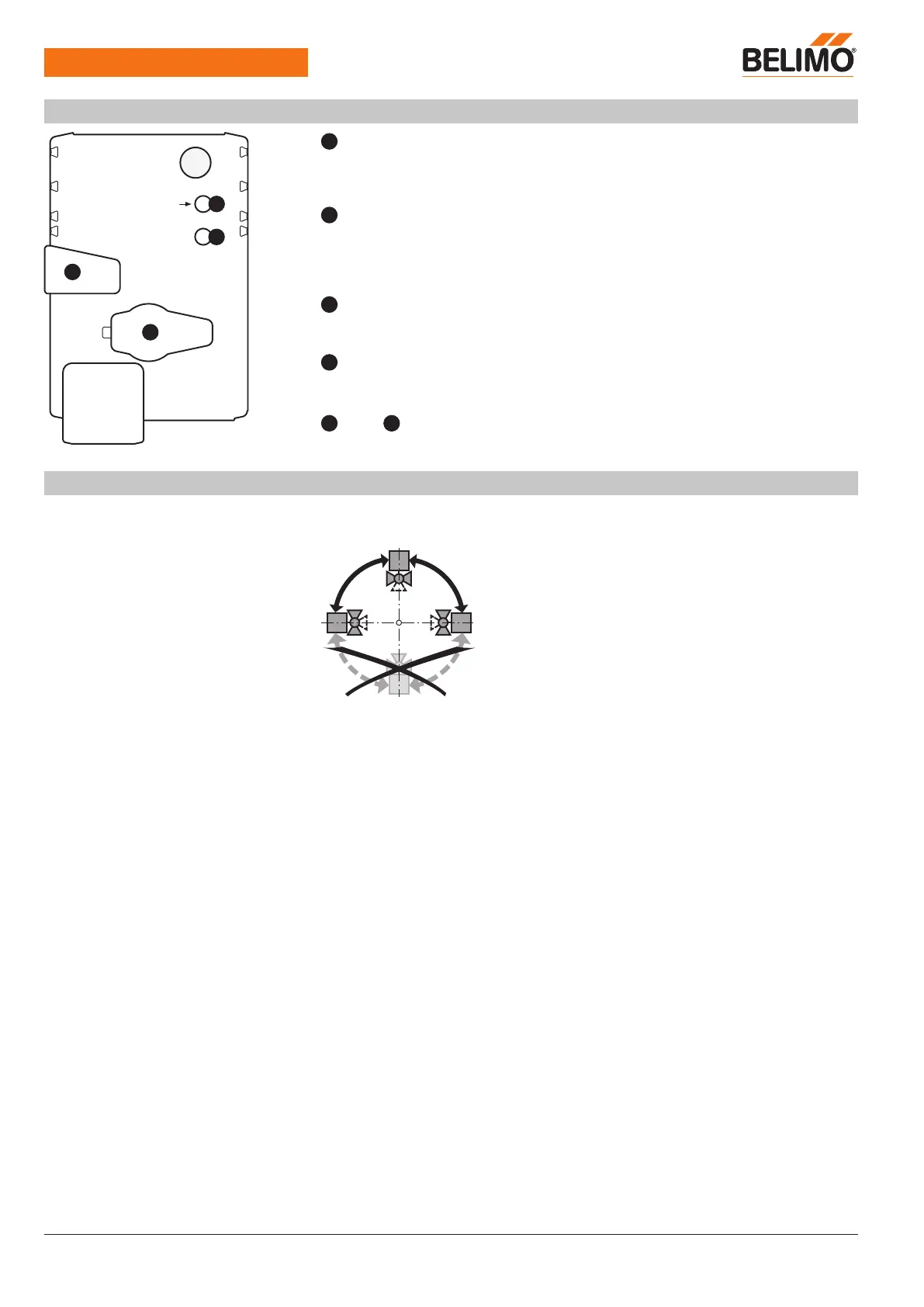

Status

2

3

4

5

2

Push-button and LED display green

Off:

On:

Press button:

No power supply or malfuntion

In operation

Triggers angle of rotation adaptation, followed by standard mode

3

Push-button and LED display yellow

Off:

Flickering:

On:

Press button:

Standard mode without MP bus

MP communication active

Adaptation or synchronising process active

Confi rmation of the addressing

4

Gear disengagement button

Press button:

Release button:

Gear disengages, motor stops, manual override possible

Gear engages, synchronisation starts, followed by standard mode

5

Service plug

For connecting parameterisation and service tools

Check power supply connection

2

Off and

3

On

Possible wiring error in power supply

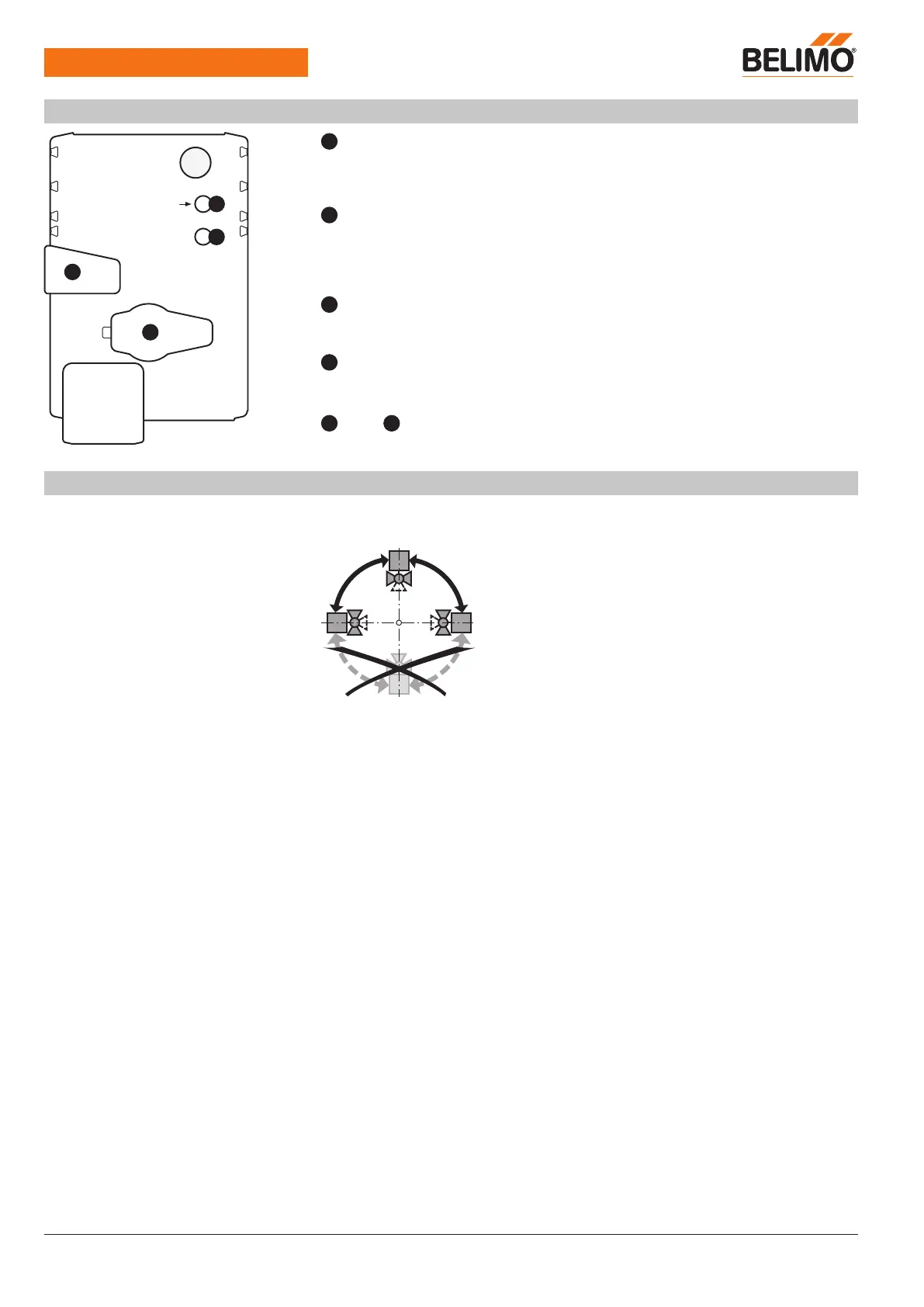

Installation notes

Recommended installation positions

The ball valve can be installed upright to horizontal. The ball valve may not be installed

in a hanging position, i.e. with the stem pointing downwards.

90

0°

Mounting position in the return

Installation in the return is recommended.

Water quality requirements

The water quality requirements specified in VDI 2035 must be adhered to.

Belimo valves are regulating devices. For the valves to function correctly in the long

term, they must be kept free from particle debris (e.g. welding beads during installation

work). The installation of suitable strainer is recommended.

The water must exhibit a conductivity ≥ 20 μS/cm during operation for correct

functioning. It should be noted that, under normal circumstances, even filling water

with a lower conductivity will experience an elevation of its conductivity to above

the minimum required value during filling and that the system can thus be put into

operation.

Elevation of conductivity during filling caused by:

- untreated residual water from pressure test or pre-rinsing

- metal salts (e.g. surface rust) dissolved out of the raw material

Stem heating

In cold water applications and warm humid ambient air can cause condensation in

the actuators. This can lead to corrosion in the gear box of the actuator and causes a

breakdown of it. In such applications, the use of a stem heating is provided.

The stem heating must be enabled only when the system is in operation, because it

does not have temperature control.

Servicing

Ball valves, rotary actuators and sensors are maintenance-free.

Before any service work on the final controlling device is carried out, it is essential to

isolate the rotary actuator from the power supply (by unplugging the electrical cable

if necessary). Any pumps in the part of the piping system concerned must also be

switched off and the appropriate slide valves closed (allow all components to cool

down first if necessary and allways reduce the system pressure to ambient pressure

level).

The system must not be returned to service until the ball valve and the rotary actuator

have been correctly reassembled in accordance with the instructions and the pipeline

has been refilled by professionally trained personnel.

EP..F+MP

Electr. 2-way PI-CCV EPIV, Flange, PN 16

Operating controls and indicators

www.belimo.com

EP..F+MP • en-ap • 2019-06-03 • subject to changes

8

Loading...

Loading...