5. Preparation

Check again whether wiring is done correctly before installing the

front unit.

Turn ON the power supply.

After initialization of the system, the output voltage set value is

indicated on the set value display.

6. Let’s use

Let’s move the vibrator.

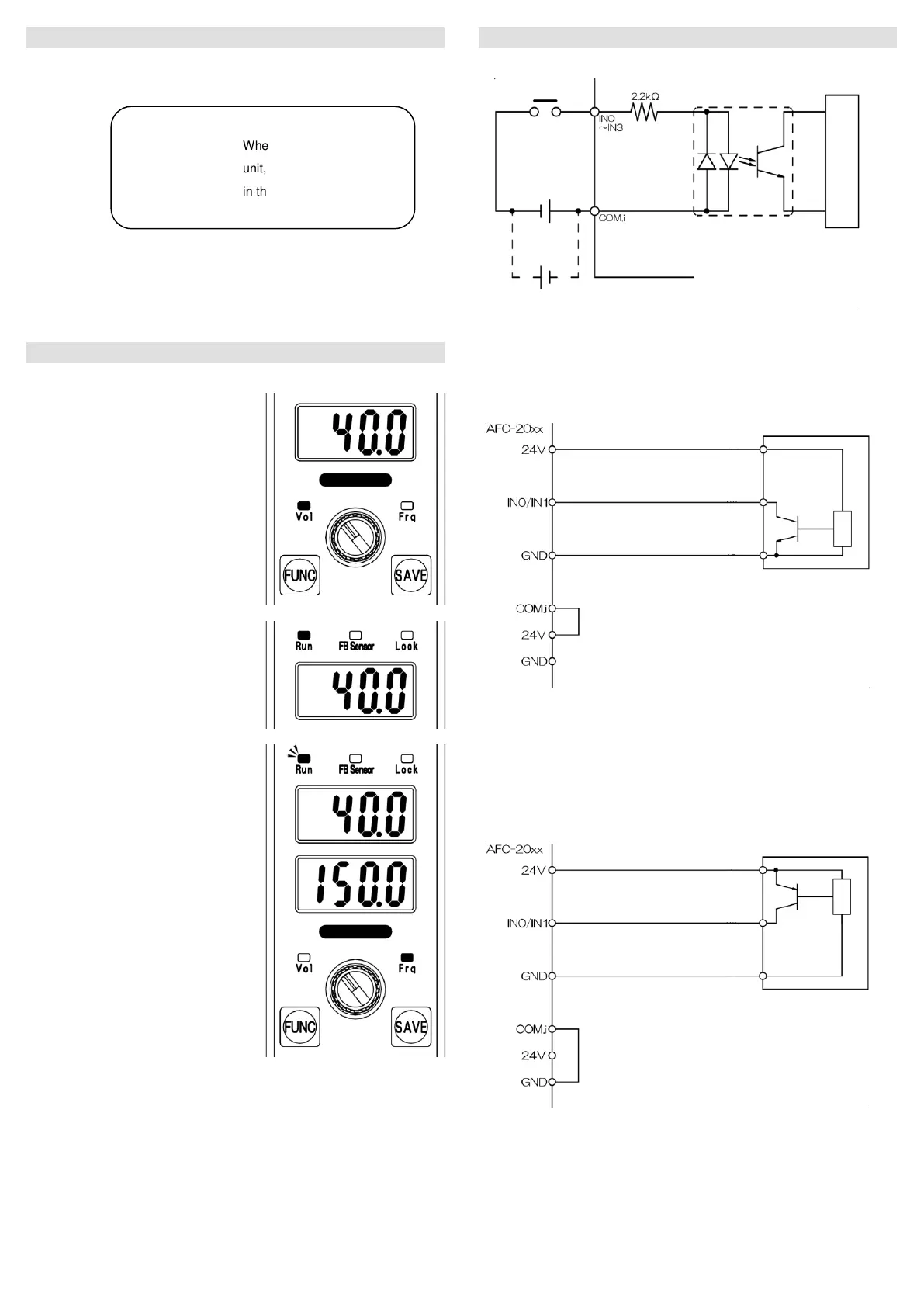

6-1 Press the FUNCTION key to turn

ON the voltage lamp and change

the output voltage set value to 40.0

by using an encoder.

Press the SAVE key to determine

the change.

6-2 If Run is OFF, press the

RUN/STOP button to turn it ON.

If Run is blinking, check the

operation signal.

The vibrator changes to operation

state if the operation signal is input.

6-3 Press the FUNCTION key to turn

ON the frequency lamp and adjust

the vibration to an area near the

strongest state (resonance point)

by using an encoder.

After adjustment, press the SAVE

key to save the change.

*The resonance point is between

75 to 250 Hz, although the value

varies depending on the load.

*If the vibration is weak and the area where it becomes strong is

difficult to find out, increase the output voltage set value.

6-4 After determining the optimal frequency, change the voltage set value

and obtain an appropriate vibration.

7. Connection with external devices

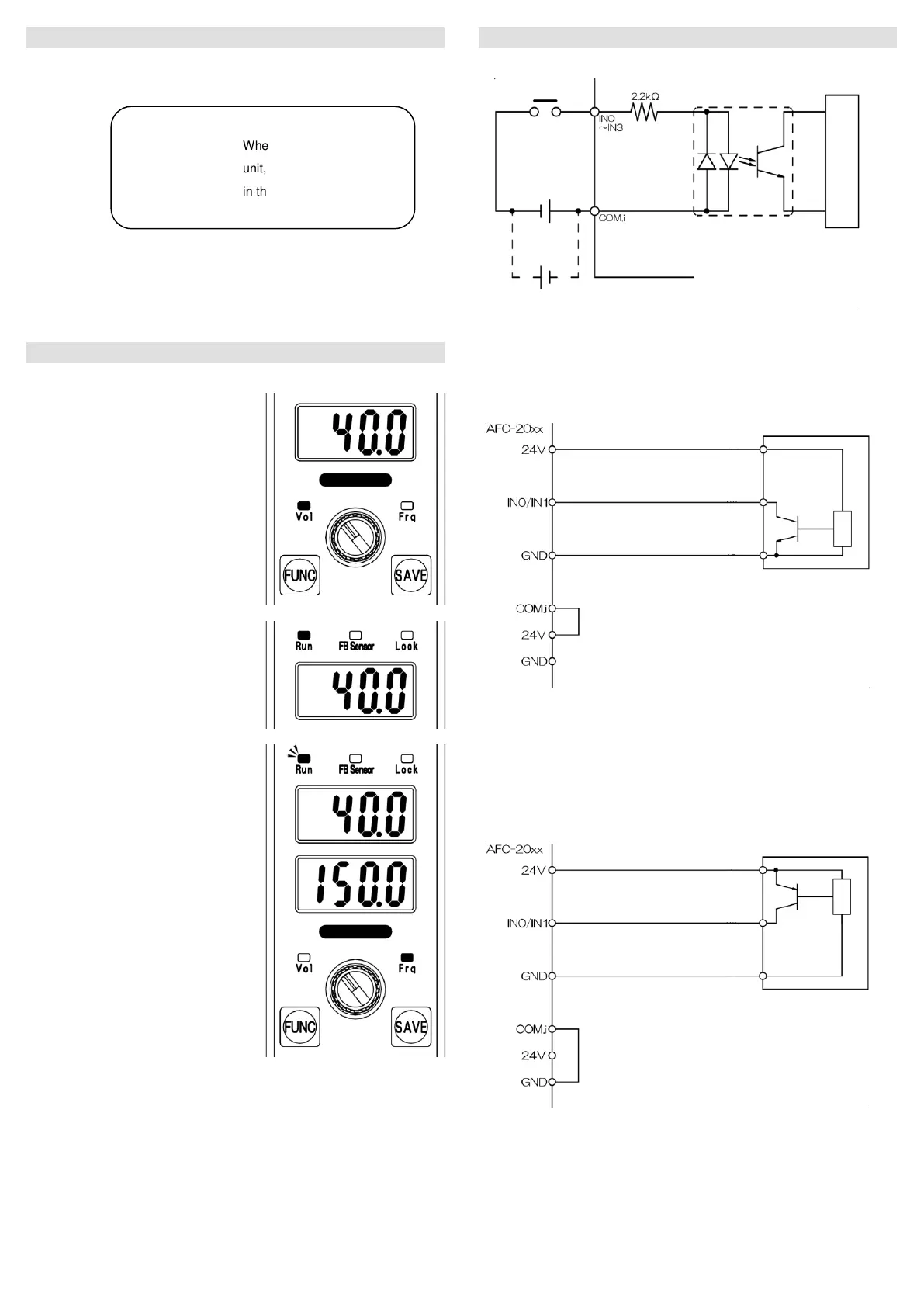

7-1 Input circuit diagram

IN0, IN1, IN2, IN3

Rated input voltage 24 VDC 15 mA

Example of connection

Connection of NPN output sensor

1 Short-circuit COM.i and 24 V of the equipment.

2 Connect 24 VDC of the sensor to 24 V of the equipment.

3 Connect the sensor output to IN0/IN1 of the equipment.

4 Connect 0 V of the sensor to GND of the equipment.

Connection of PNP output sensor

1 Short-circuit COM.i and GND of the equipment.

2 Connect 24 VDC of the sensor to 24 V of the equipment.

3 Connect the sensor output to IN0/IN1 of the equipment.

4 Connect 0 V of the sensor to GND of the equipment.

When installing the front

unit, do not tuck in or push

in the flat cable forcibly.

! Caution

Power supply to input circuit

Loading...

Loading...