7

D

3

10

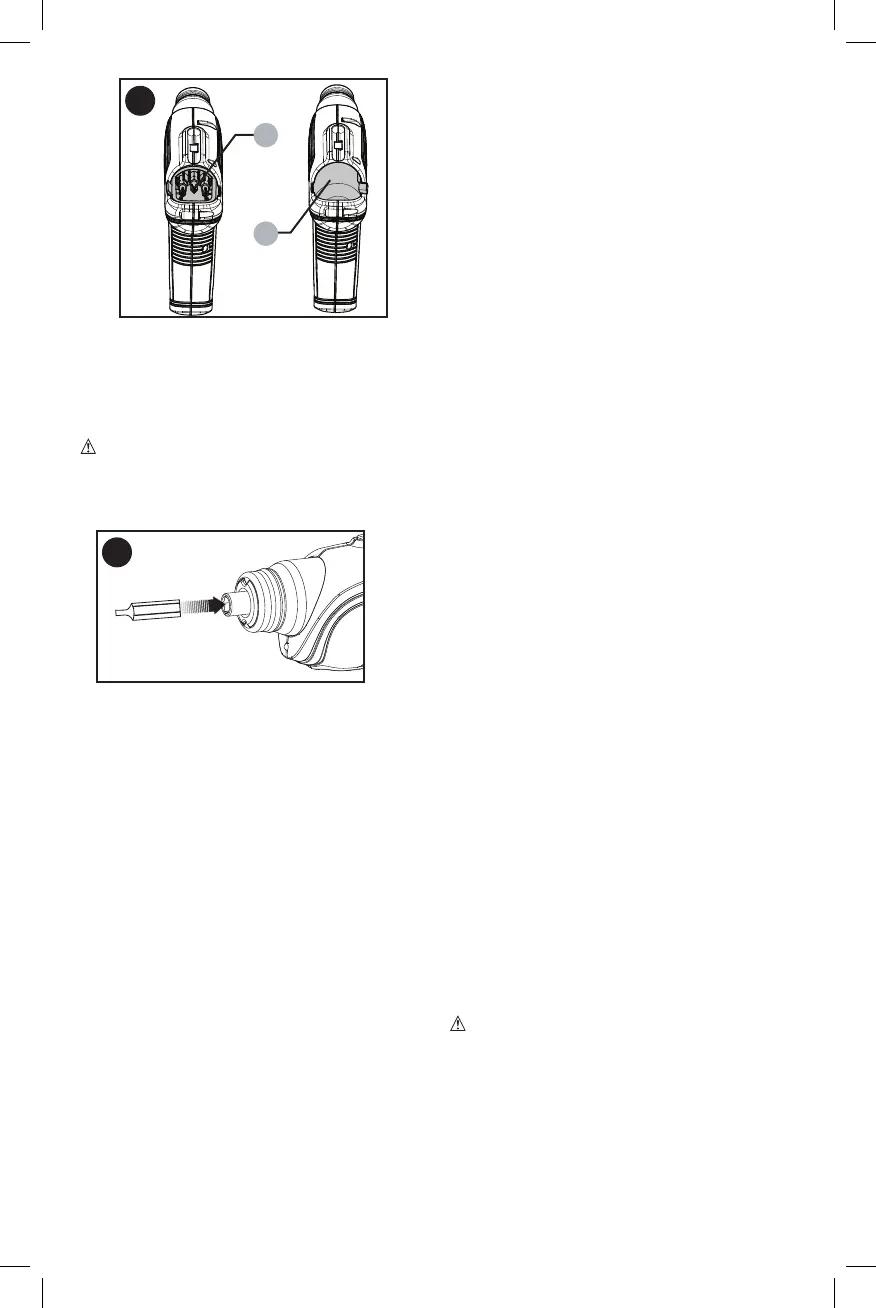

INSERTING AND REMOVING BITS

• To install a bit, insert it into the cavity in the

hex spindle as shown in Figure E.

• To remove the bit, pull it straightout.

• For bit tips, use a bit tipextender.

NOTE: Only hex end bits will fit in spindle

WARNING:

• Do not use screwdriver as a pry bar in

anyposition.

• To avoid screwdriver being turned on

accidentally, do ot cary in yourpocket.

E

OPERATING INSTRUCTIONS

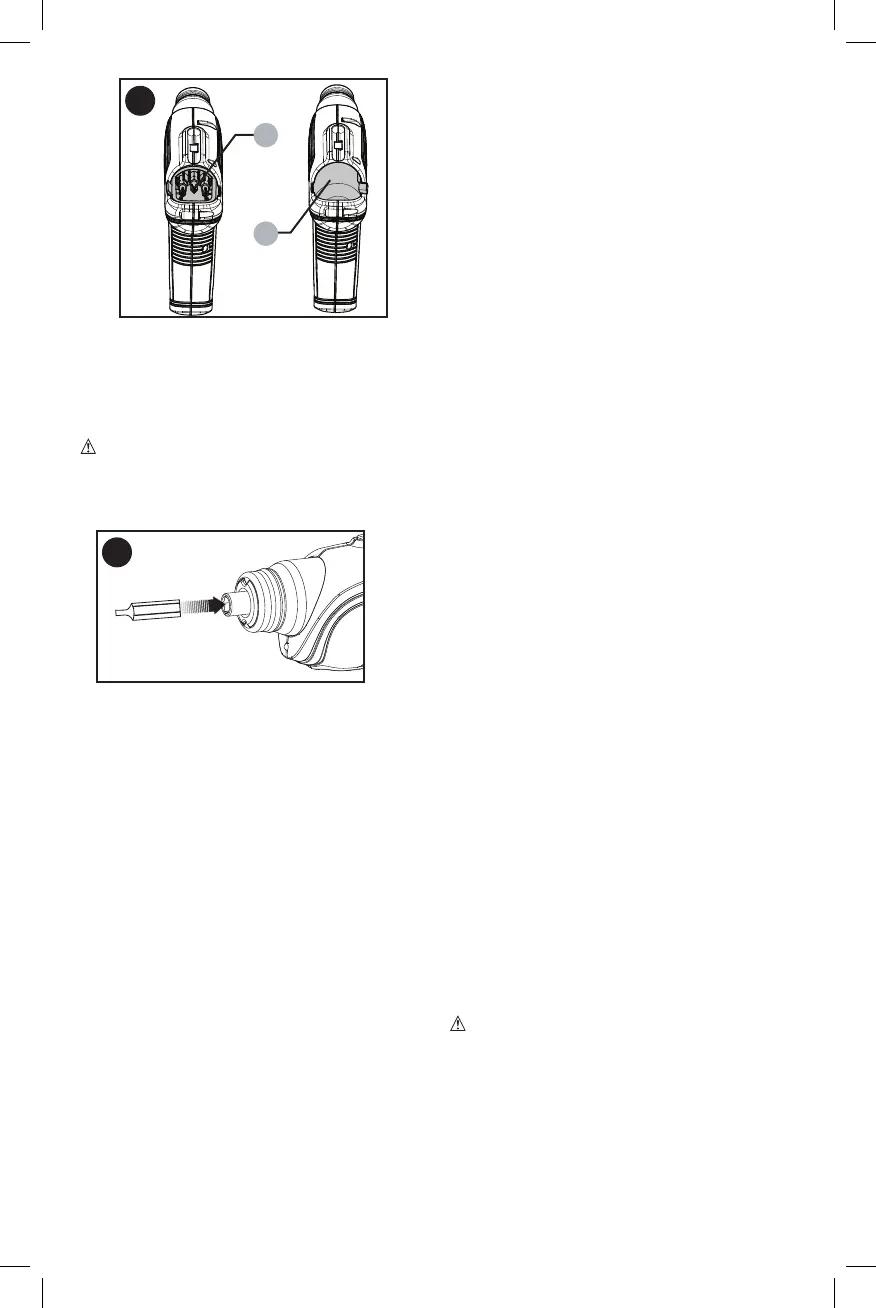

TRIGGER SWITCH & REVERSING BUTTON

• The drill is turned ON and OFF by pulling

and releasing the trigger (1).

• The forward/reverse control button (2)

determines the direction of the tool and

also serves as a lock off button.

• To select forward rotation, release the

trigger switch and depress the forward/

reverse control button to the left.

• To select reverse, depress the forward/

reverse control button the oppositedirection.

NOTE: When changing the position of the

control button, be sure the trigger is released.

LED LIGHT

When the screwdriver is activated by pulling

the trigger switch (1), the LED light (5) will

automatically come on. The light will go off

when the trigger isreleased.

MAGNETIC SCREW HOLDER

Place a few screws in the magnetic screw

holder (4), so your screws are right there to

help make the jobeasier.

SCREW DRIVING

For driving fasteners, the foward/reverse button

should be pushed to the left. Use reverse (button

pushed to the right) for removing fasteners.

When moving from forward to reverse, or vice

versa, always release the trigger switch first.

Release trigger when the fastener is at the

desireddepth.

NOTE: For best performance, #8, 2” fasteners

are recommended, or screw into pre-drilled holes

(1/16 - 5/32 bit recommended).

DRILLING

• Insert the appropriate hex shank drillbit.

• Select forwardrotation.

GENERAL DRILLING TIPS

• This tool is not recommended for drilling

inmasonry.

• Use sharp drill bits only

• Drill bits for metal can be used for drilling

holes in wood. These bits must be sharp

and should be pulled out frequently when

drilling to clear chips from theflutes.

• Support and secure work properly, as

instructed in the safety Instructions.

• Use appropriate and required safety

equipment, as instructed in the

safetyinstructions.

• Secure and maintain work area, as

instructed in the safety instructions.

• Use light pressure until the hole is started

enough to keep the drill bit from slipping

out ofit.

• Apply pressure in a straight line with the bit.

Use enough pressure to keep the bit biting

but not so much as to stall the motor or

deflect thebit.

• Hold the tool firmly to control its twistingaction.

• DO NOT CLICK THE TRIGGER OF A

STALLED TOOL OFF AND ON IN AN

ATTEMPT TO START IT. DAMAGE TO THE

TOOL CAN RESULT. To remove:

• Put tool in reverse and back drill bitout.

• Turn tool off and back bit out byhand.

• Remove bit withpliers.

• Minimize stalling on breakthrough by

reducing pressure and slowly drilling

through last part of hole.

• Put tool in reverse while pulling the bit out of a

drilled hole. This will help reducejamming.

• Make sure switch turns tool on andoff.

WARNING: It is important to support

work properly and to hold the tool firmly to

prevent loss of control which could cause

personalinjury.

MAINTENANCE

Use only mild soap and damp cloth to clean

the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into aliquid.

IMPORTANT: To assure product SAFETY

and

RELIABILITY, repairs, maintenance and adjustment

Loading...

Loading...