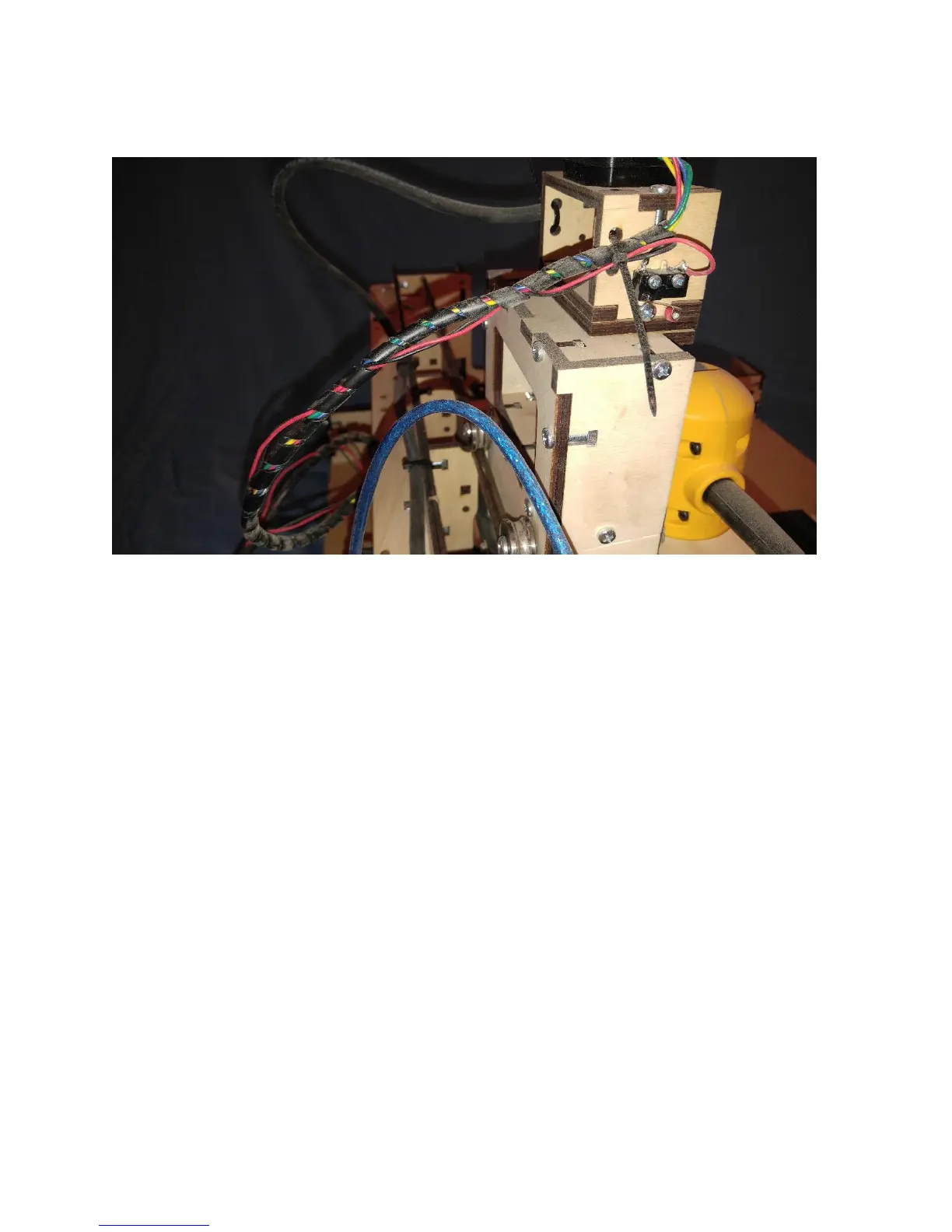

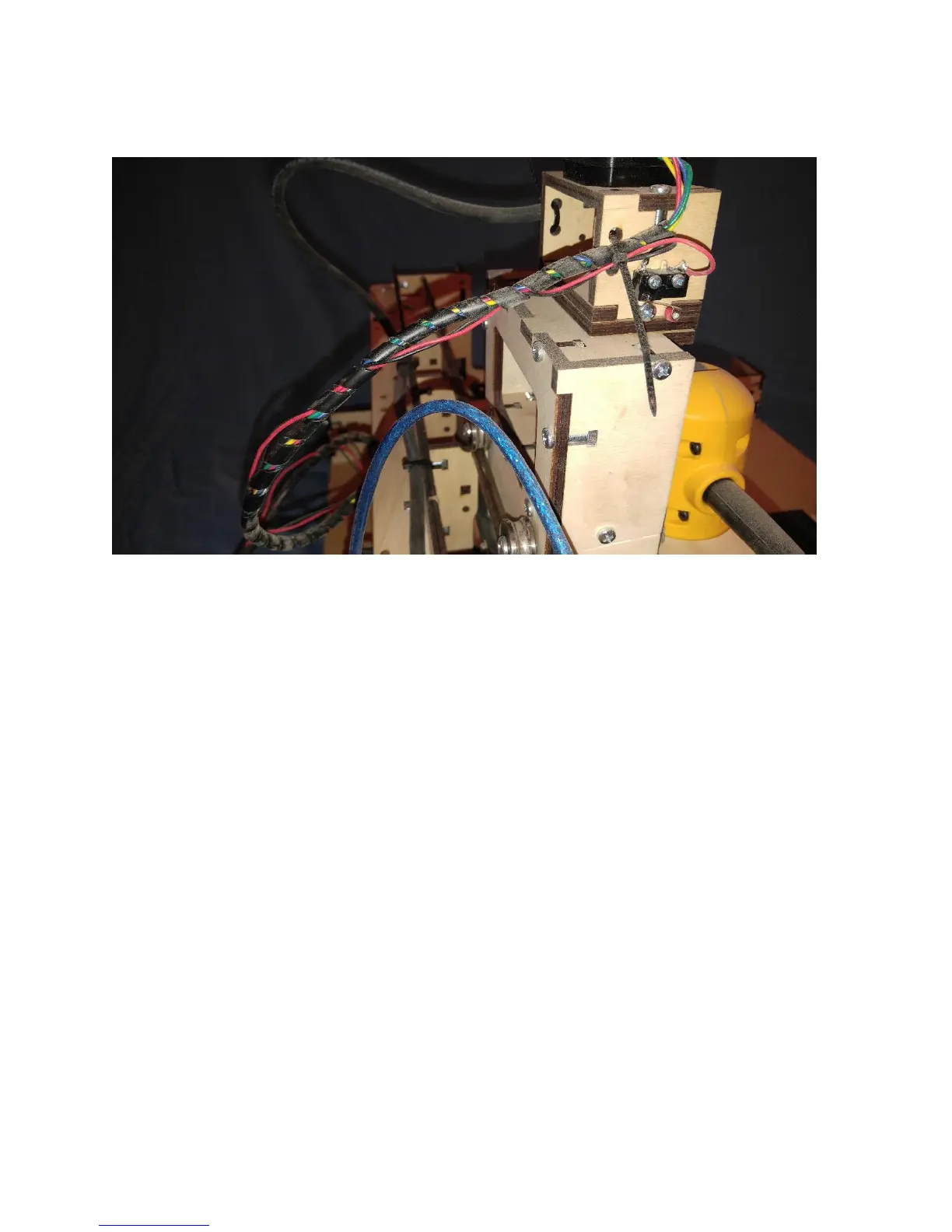

1. There is electrical noise in the Z home switch caused by the Z stepper motor wires. You can

separate the home switch wire and wrap every 5 or 6 loops like in the picture.

2. Binding in the system. The stepper motors only have so much torque and cannot drive thru

the binding. This can be solved by reducing friction in the system. The screw should turn easily.

Possible solutions are:

• Spraying dry lube (graphite, Teflon, or silicon) on the threaded rod.

• Ensure that the brass nuts with the rubber washers are not too tight. The optimal nut

flat selection is as loose as possible without axial movement of the threaded rod.

• Ensure the aluminum helical coupler has space left between the helical cut to help with

misalignment. Tighten the coupler to the Z stepper motor shaft, then pull the coupler

down, stretching it about 1 mm. While stretched, tighten the set screws to the threaded

rod.

3. Stepper motor current too low – The stepper motor driver is not suppling enough current for

the stepper motor to drive the screw. Turn up the stepper motor current on the A4988 driver.

4. Stepper motor current too high – The stepper motor driver is heating up and going into

protection mode. Once it cools it turns back on. This can look like erratic stepper motor

movement. Turn down the stepper motor current on the A4988 driver.

Loading...

Loading...