| 39

Installation Instructions

Bosch IDS BOVA15 Split System Heat Pump - BTC 761701317 A (02.2022)

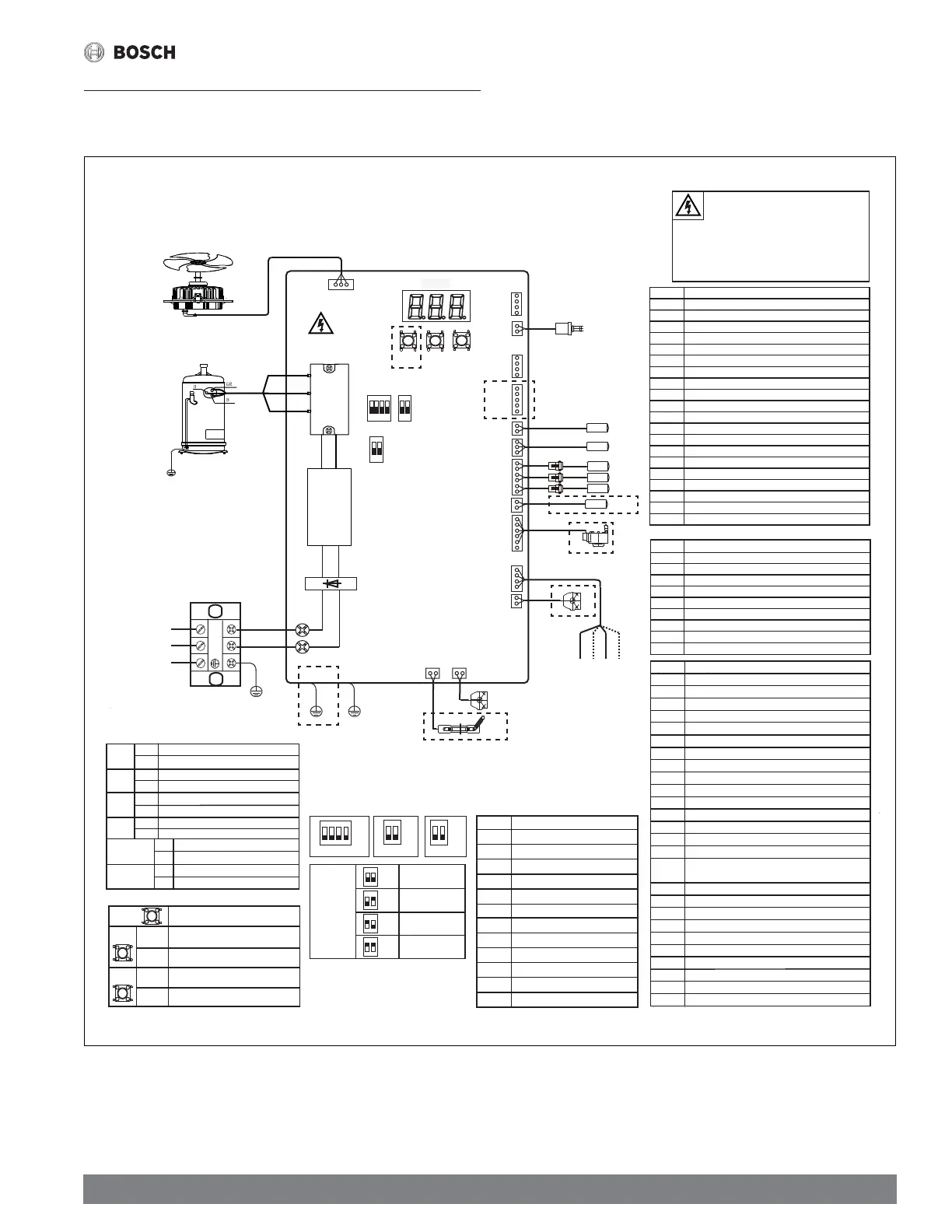

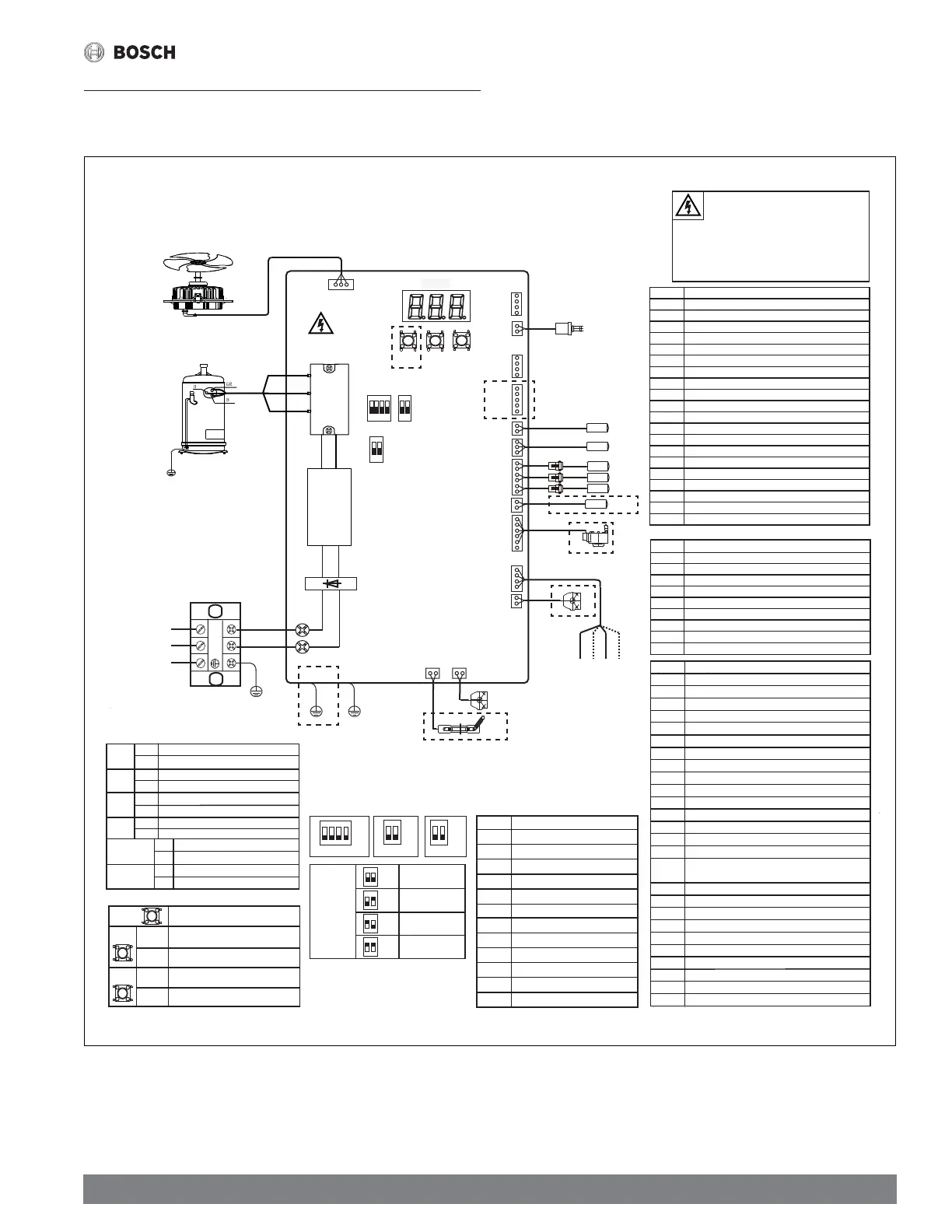

16 Wiring Diagram

16.1 BOVA24/36-15 (2/3 Ton)

Figure 60

SW4

1 2 3 4

ON

SW5

1 2

ON

SW1

FORCE

CN10

CN25

CN21

CN7

CN20

CN13

HPS

T5

PT

T3

T4

T3L

Th/T6

RV

EEV

CN14

CN16

CN9

CN12

PEV

CN17

DSP1

IPM

Main Board

GR/W

BR/V

BK/U

CN32

FAN

CN1 L1

CN2 L2

Y/G

Y/G

Power in

Terminal block

CCH

CN8

FORCE

PRESS

6s

PRESS

1s

SS

ERPSSERP

s1s1

PRESS

6s

CHECK

Detailed

reference manual instructions

SW3

Wifi setting(reserve)

YELLOW

WHITE

BLUE

C B Y W

To thermostat

USE COPPER

CONDUCTORS ONLY

Check the system parameters

Test mode(Not used)

Forced cooling/heating

(Charge mode)

PFC

Forced defrosting

V2 U2

BROWN

BLACK

WHITE

BLUE

Note:

1.B terminal to be connected with

themostat(O/B) wiring heat pump

heating operating,energized for heating.

2.EEV、RV for HP system.

3.B、W signal for HP system.

ORANGE

RED

BK

*

6:

21

ON

OFF

*The factory Default

*

21

6:

ON

OFF

SW5-1

Enter defrost

SW5-2

Quit defrost

OFF

ON

OFF

ON

Normal

SW4-2

SW4-3

SW4-4

OFF

ON

SW4-1

Normal

ON

OFF

*

*

*

*

*

OFF

ON

OFF

ON

Unused

For 48K model

For 60K model

Must be set at OFF position

Unused

Must be set at OFF position

Adaptive capacity output disable

Adaptive capacity output enable

Normally cooling/heating

Accelerated cooling/heating

Operating time is reduce 10%

Defrosting extended for 60 seconds

CN11

*

W2

SW6

1 2

ON

SW2

CHECK

SW3

6:

21

ON

OFF

For 24K model

For 36K model

21

ON

OFF

21

ON

OFF

21

ON

OFF

21

ON

OFF

Set capacity

Y/G

GND1 GND2

COMP.

L1

L2

Mumber Point check content

0

Outdoor unit capacity,example:H3=Heat pump 3 ton

1 Outdoor unit mode:0-standby,2-cooling,3-heating

2 Outdoor unit set compressor speed(Hz)

3 T3:outdoor coil temp.(°F)

4 T4:outdoor ambient temp.(°F)

5 T5:compressor discharge temp.(°F)

6 Reserve

7 T3L:(liquid line temp.)(°F)

8 Tf:module temp.(°F)

9 Pe:evaporating pressure(PSI)

10 Pc:condensing pressure(PSI)

11

Tes target evaporating temp.(only for cooling mode)(°F)

12 Te:evaporating temp.(°F)

13 Tcs target condensing temp(only for heating mode)(°F)

14 Tc:condensing temp.(°F)

15

Target of the compressor discharge superheat

(heating mode only):Target value (°F)

16 Compressor diacharge superheat(°F)

17 Opening of EEV

18 Outdoor fan speed

19 Compressor current(A)

20 Power AC voltage Input(V)

21 Compressor input dc voltage (V)

22 Continuous running time of the compressor(min)

23 Last fault code

24 Software version

25 Remark"--"

HPS

High pressure switch

T5 Comp. discharge temp. sensor

PT Pressure transducer

T3 Condensor temp. sensor

T4 Ambient temp. sensor

T3L Condensor outlet temp. sensor

Th/T6

Comp. return temp. sensor

EEV Electric expansive valve

RV Reversing valve

PEV Pressure equalizer valve

CCH Crankcase heater

COMP. Compressor

TEMP. Temprature

CODE

CODE

Fault description

Description

E4 Temprature sensor fault (T3,T4,T5,T3L,TF)

F1 High pressure switch fault (HPS)

H8 Pressure transducer fault (PT)

E6 DC fan motor fault

P8 DC fan motor hurricane/typhoon protection

E5 High/Low voltage protection

E9 EEPROM fault

H0 Communication fault in main control chip

L0-L9 The IPM module protection(only for analysis)

C3 The coil sensor is seated fault in cooling(T3)

E7 Compressor discharge sensor is seated fault (T5)

PH Low discharge superheat protection

P1 High pressure(HPS) protection

P5

Condensor coil temperature protection in cooling (T3)

P4 High T5 protection

P0 HighControl board temperature protection (TF)

P3 Compressor over current protection

P2 Low pressure protection in cooling or heating (PT)

H5 5 times (P2) protection in 100 minutes, lockup

AtL Ambient Temperature Limited T4 (heat pump)

┣

Forced operation mode

L Running indication under T3 limited condition

D Running indication under T5 limited condition

P Compression ratio protection limit

F Running indication under TF limited condition

C

Running indication under current limited condition

U

Running indication under low voltage limited condition

A Running indication under return oil model

dF Running indication under defrost model

U

V

W

Y/G

5

.

WARNING

FAILURE TO FOLLOW THIS WARNING COULD RESULT

IN PERSONAL INJURY OR DEATH

ELECTRIC HAZARD 380 VOLTS DC

WAIT 3 MINUTES AFTER DISCONNECTING POWER,THEN

VERIFY DC VOLTAGE LESS THAN 42 VDC AT INVERTER

TEST POINTS P-N. COMPONENTS MAY STORE A

DANGEROUS ELECTRICAL POTENTIAL OF 380 VOLTS DC.

SW6

Loading...

Loading...