6 | Condensate Drain LM CS Series Heat Pump

LM CS Series Heat Pump8 733 920 847 (2014/01) Subject to change without prior notice

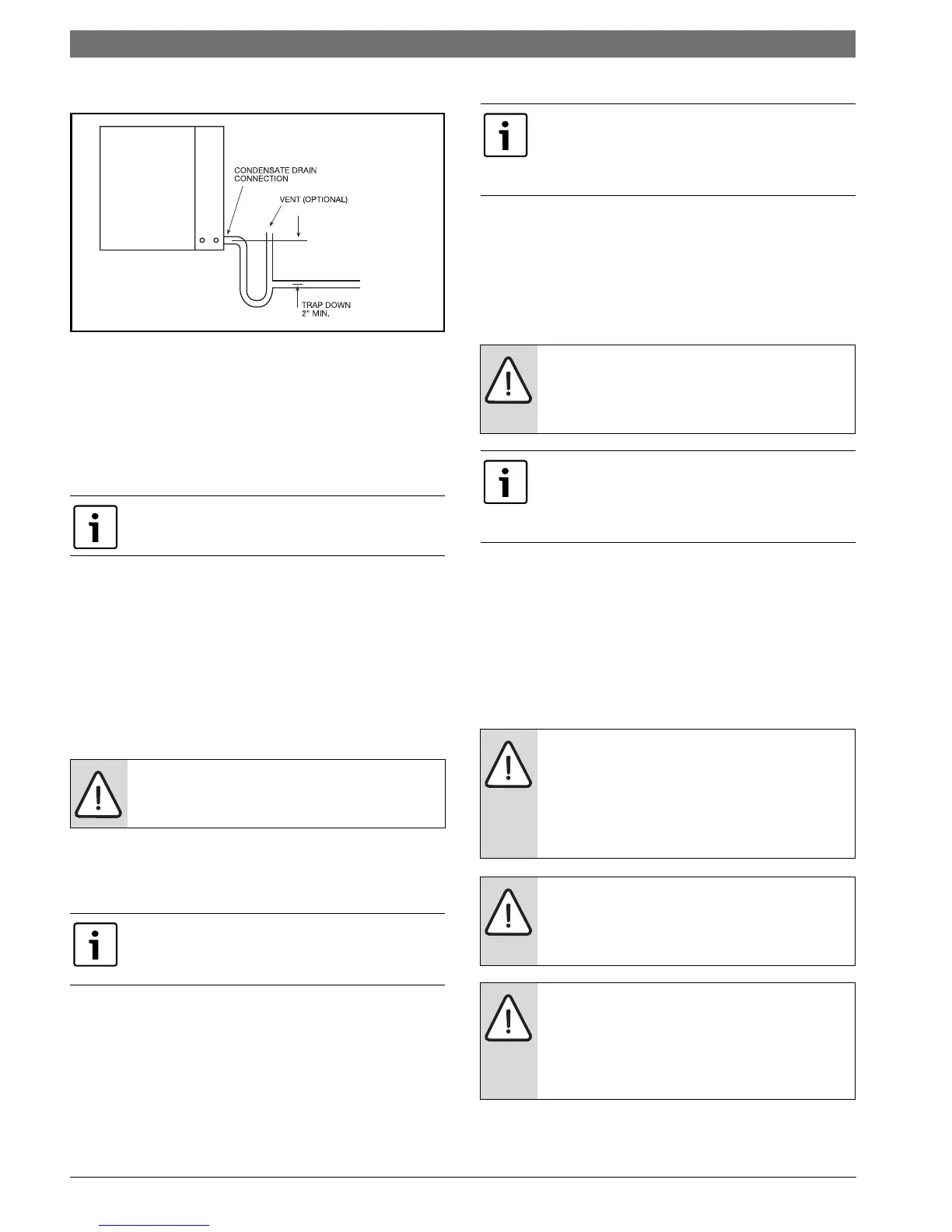

CONDENSATE DRAIN

Figure # 3

A drain line must be connected to the air handler

and pitched away from the unit a minimum of 1/8”

per foot to allow the condensate to flow away from

the unit.

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate flow.

A vertical air vent is sometimes required to avoid

air pockets. The length of the trap depends on the

amount of positive or negative pressure on the

drain pan. A second trap must not be included.

WATER PIPING

Supply and return piping must be as large as the

unit connections on the heat pump (See manual

Pg#10 for any line size at installation length longer

than 25 feet).

LM units are supplied with either a copper or

optional cupro-nickel condenser. Copper is

adequate for ground water that is not high in

mineral content.

In conditions anticipating moderate scale

formation or in brackish water a cupro-nickel heat

exchanger is recommended.

Both the supply and discharge water lines will

sweat if subjected to low water temperature.

These lines should be insulated to prevent damage

from condensation. All manual flow valves used in

the system must be ball valves. Globe and gate

valves must not be used due to high pressure drop

and poor throttling characteristics.

Flexible hoses should be used between the unit

and the rigid system to avoid possible vibration.

Ball valves should be installed in the supply and

return lines for unit isolation and unit water flow

balancing.

ELECTRICAL

Refer to electrical component box layout.

(Figures #5,6)

Drain Pan is not internally sloped.

Never use flexible hoses of a smaller inside

diameter than that of the fluid connections

on the unit.

Proper testing is recommended to assure the

well water quality is suitable for use with water

source equipment.

Use cupra-nickel condenser in ground

water application due to possibility of

containing high mineral and corrosive

properties

Never exceed the recommended water flow

rates, as serious damage or erosion of the

water-to-refrigerant heat exchanger could

occur.

Teflon tape sealer should be used when

connecting water piping connections to the units

to insure against leaks and possible heat

exchanger fouling.

Field wiring must comply with local and

national electric codes. Properly sized fuses

or HACR circuit breakers must be installed

for branch circuit protection. See unit

nameplate for maximum fuse or breaker

size.

Power to the unit must be within the

operating voltage range indicated on

the unit nameplate or on the

performance data sheet.

Operation of unit on improper line

voltage or with excessive phase

imbalance will be hazardous to the unit,

constitutes abuse and may void the

warranty.

Loading...

Loading...